Baking working method of electric oven

A working method and technology of an electric oven are applied in the field of oven control systems, which can solve the problems of reducing market competitiveness, undercooking, and scorching of food, and achieve the effect of realizing automatic cooking of food.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

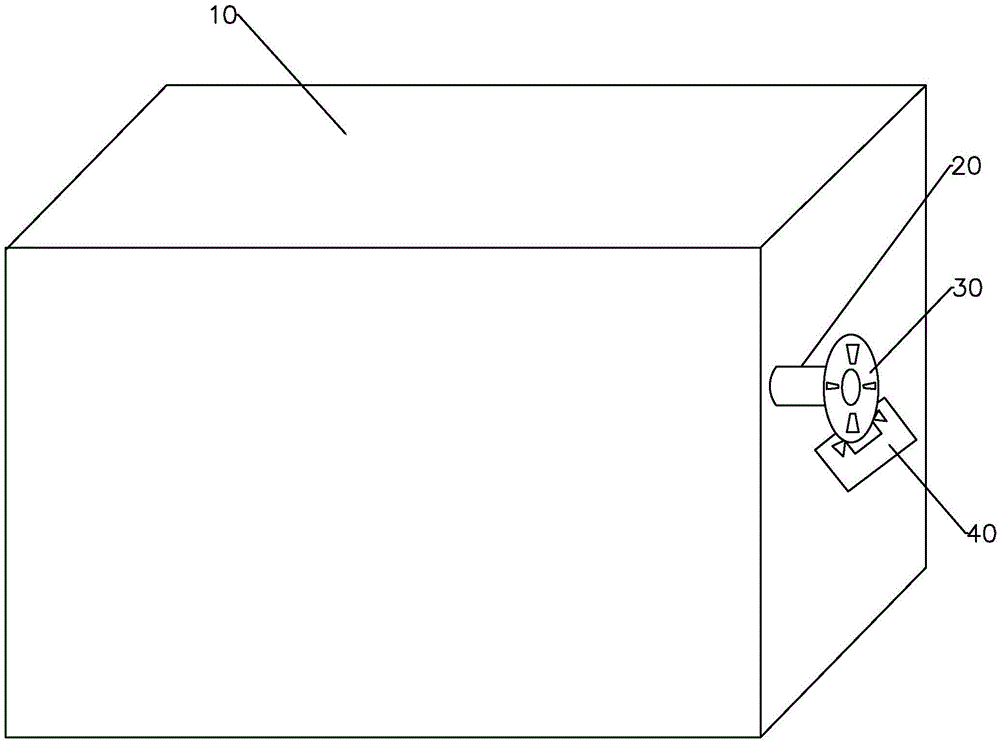

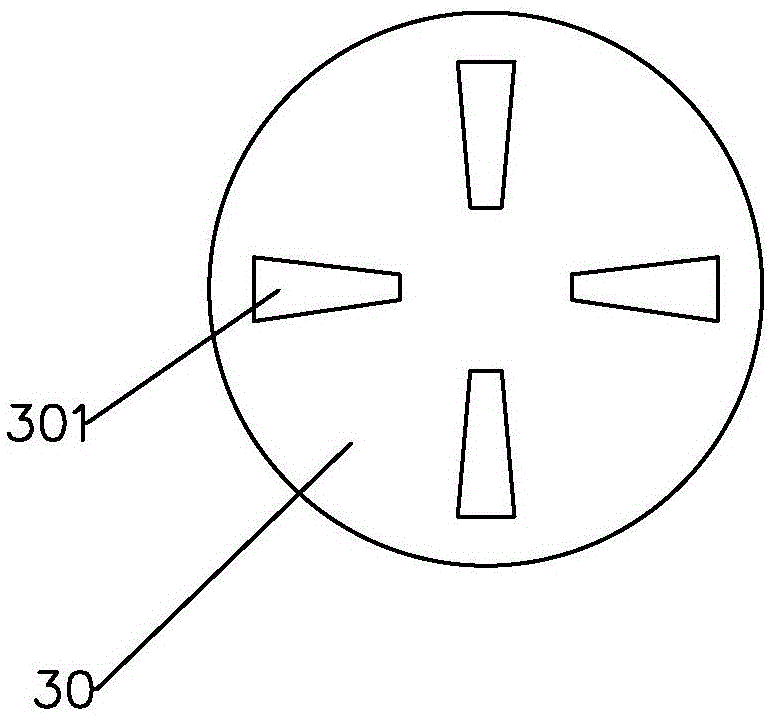

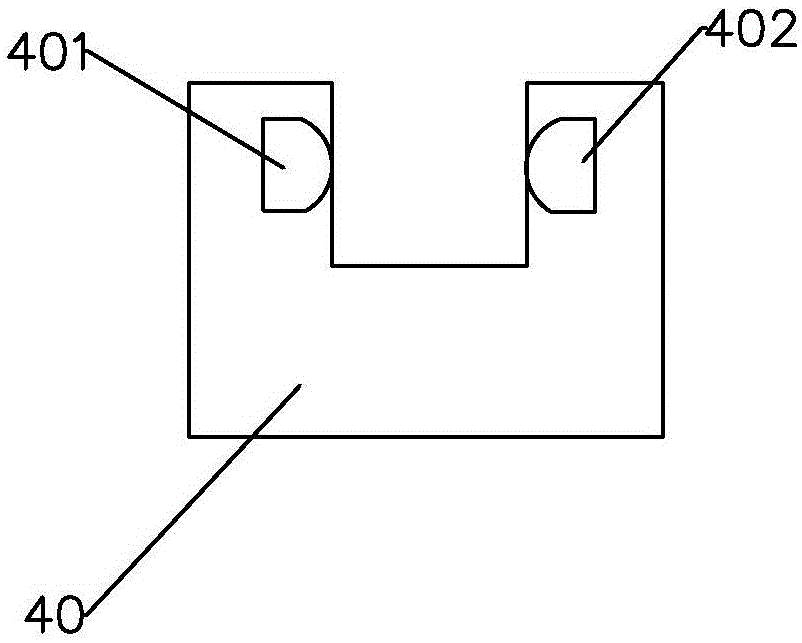

[0019] like Figure 1-Figure 3 As mentioned above, in order to implement the food weight detection of the oven 10 of the present invention, a turntable 30 that rotates synchronously and has a grid 301 is set on the barbecue fork shaft 20, and an infrared emitting and receiving device 40 is arranged outside the rotating disk 30, and the infrared emitting and receiving device 40 includes a transmitter transmitter 401 and receiver 402, the transmitter 401 transmits a signal from one side of the turntable 30, and when the signal passes through the grid 301, it is received by the receiver 402 on the other side of the turntable 30, and the interval between two consecutive receptions of the signal by the receiver 402 is Rotation cycle of the spit.

[0020] Baking working method of the present invention comprises the following steps:

[0021] S1. Measuring the period T of the barbecue fork when it is unloaded 0 ;

[0022] S2. Fix the food on the barbecue fork, and measure the perio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com