Medicine production waste liquid drainage device

A technology of pharmaceutical production and waste liquid, which is applied in the direction of grain processing, etc., can solve problems such as easy blockage of drainage pipe valves, etc., and achieve the effects of prolonging service life, convenient adjustment, and reducing frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

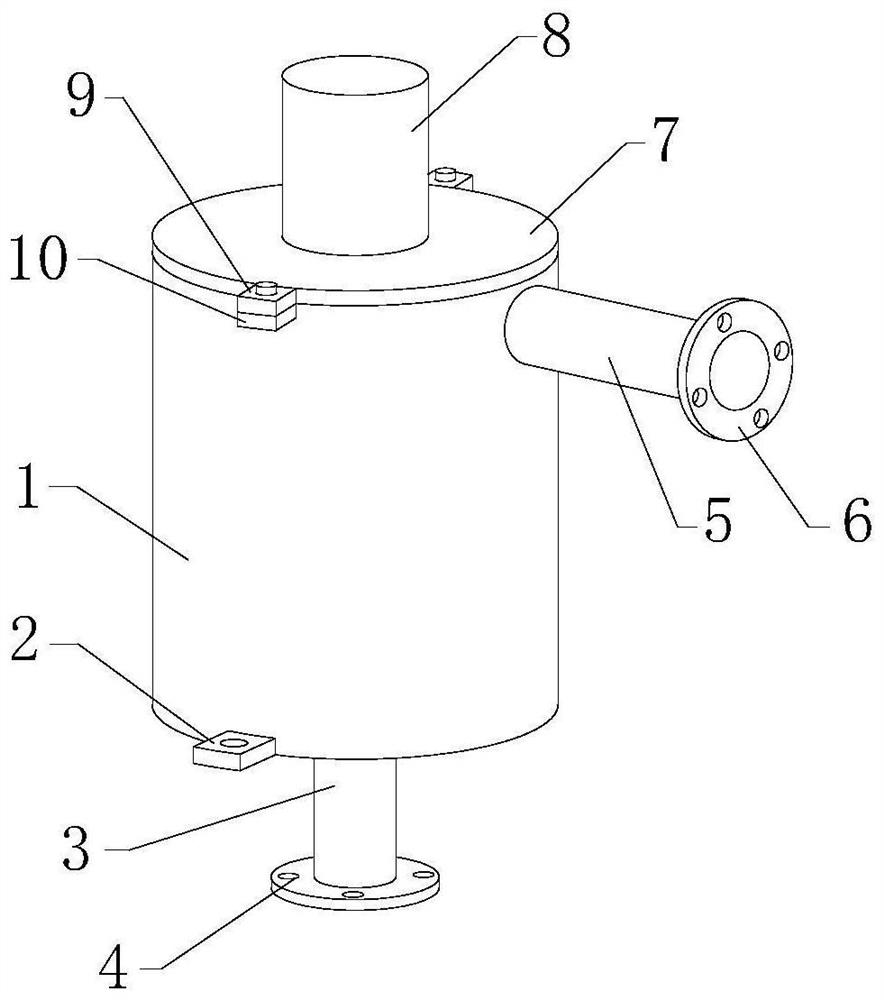

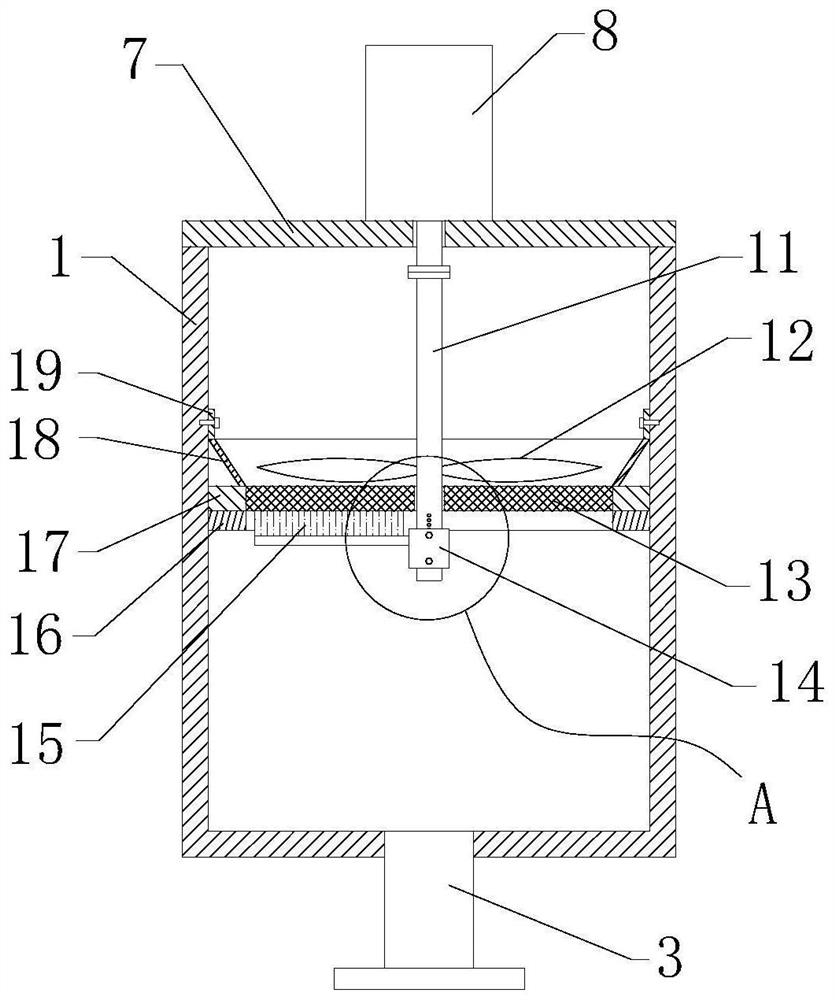

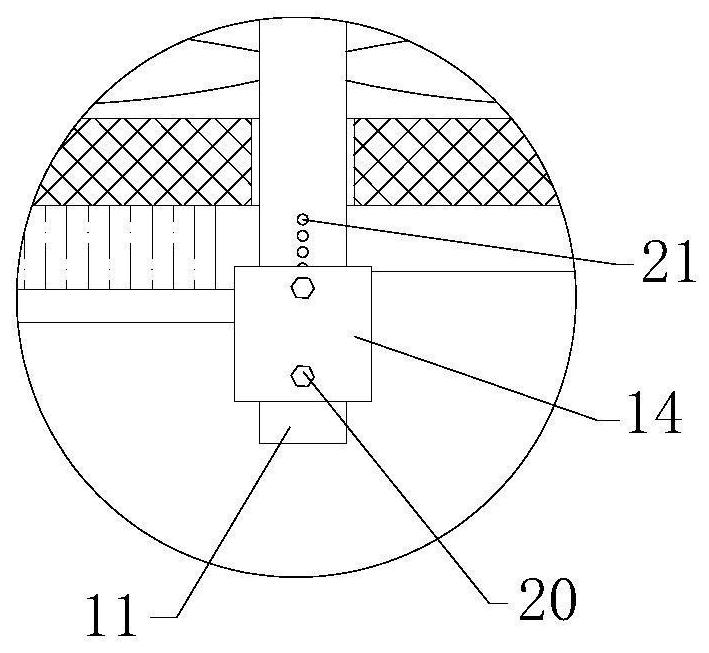

[0025] see Figure 1 to Figure 7 , the present invention provides a technical solution: a device for discharging waste liquid from pharmaceutical production, including a crushing cylinder 1, a liquid outlet pipe 3 is installed in the middle of the lower end surface of the crushing cylinder 1, and a liquid inlet pipe 3 is installed on the outer surface of the upper end of the crushing cylinder 1. Pipe 5, the upper end of the crushing tube 1 fixes the cap 7, and the cap 7 is installed on the crushing tube 1 to block the crushing tube 1, and the waste liquid generated in the pharmaceutical production process enters the crushing tube 1 through the liquid inlet tube 5 , and then the waste liquid that is filtered and pulverized is discharged through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com