Scraper discharging full-automatic control method and production line for basic copper chloride

A copper chloride, production line technology, applied in the direction of copper chloride, chemical instruments and methods, copper halide, etc., to achieve the effects of improving production efficiency, high production efficiency, and fast unloading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

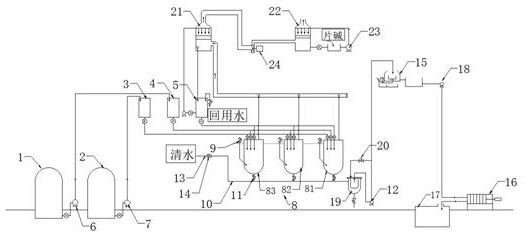

[0046] Acidic etching solution and alkaline etching solution are used as raw materials, which are temporarily stored in acidic solution tank and alkaline solution tank respectively, and then sent to acid high level tank and alkali high level tank respectively through acid delivery pump and alkali delivery pump. Open the reuse water inlet valve to introduce water into the dripping water head tank, and respectively flow the acidic etching solution, alkaline etching solution and water into the respective dripping main pipes, and drop them into the reaction barrel through the dripping valve. Under the conditions of stirring in the reaction tank and direct steam heating to 60~75°C, neutralize the three liquids in the reaction tank to reach a Baume degree of 7~12 and a pH value of 4.5~4.8. During the reaction The ammonia gas produced is recycled through the exhaust gas recovery device. When the liquid level of the dropwise reaction solution reaches 90% to 95% of the volume of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com