Quantitative analysis method for rubber concrete microstructure

A technology of rubberized concrete and microstructure, applied in the analysis of materials, permeability/surface area analysis, suspension and porous material analysis, etc. The effect of scientific and rigorous analytical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

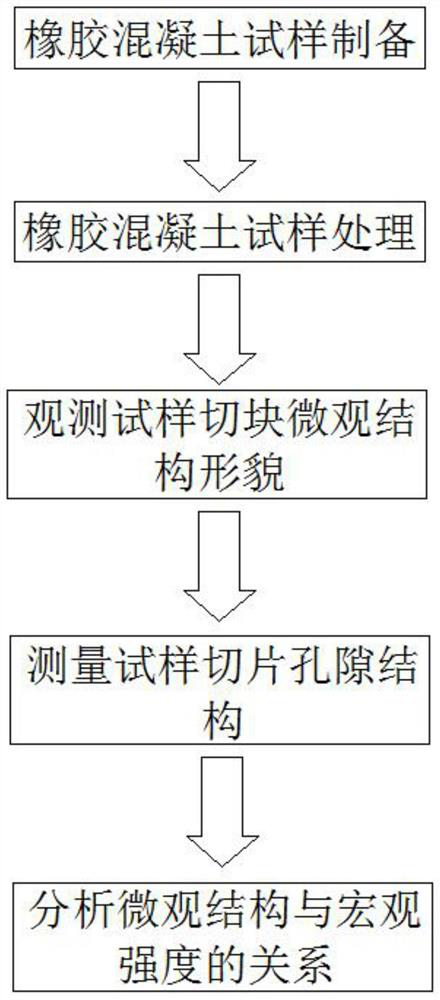

[0030] according to figure 1 , 2 As shown, the present embodiment provides a method for quantitative analysis of rubber concrete microstructure, comprising the following steps:

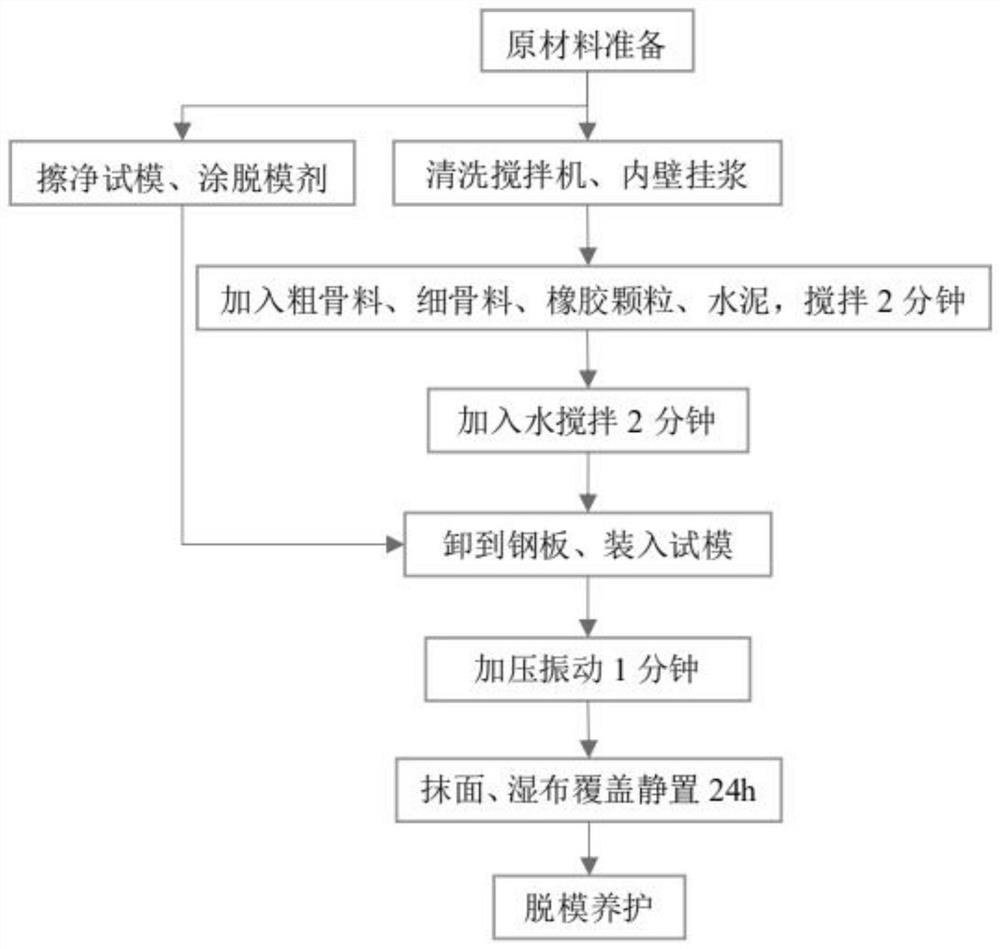

[0031] Step 1: Preparation of rubber concrete samples

[0032] First, wipe the test mold clean and evenly apply a layer of release agent, then clean the mixer and coat the inner wall of the mixer with slurry, then add the weighed coarse aggregate, fine aggregate, rubber particles, cement and sand into the mixer and Stir for 2 minutes, then add the weighed water into the mixer and continue to stir for 2 minutes. The mixing ratio between water, cement, sand, fine aggregate, coarse aggregate and rubber partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com