Method for evaluating separation effect of coarse powder separator during mixed coal grinding

A coarse powder separator and pulverized coal technology, which is applied in the testing of machines/structural components, instruments, particle size analysis, etc., can solve problems such as the inability to reflect the transformation effect of the coarse powder separator, and the inability to determine the recommended value of the optimal cycle rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] According to the technical scheme in the summary of the invention, an example is given in combination with the transformation of a certain coarse powder separator.

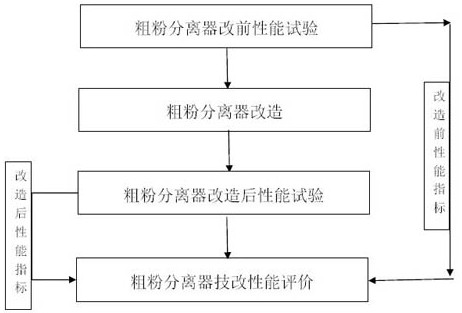

[0053] A power plant plans to renovate the coarse powder separator of a boiler storage pulverization system, and replace the coarse powder separator with a rotary-inertia coupling coarse powder separator. The performance evaluation work steps of the modification of the coarse powder separator are shown in Figure 1.

[0054] Step 1: Carry out the performance test of the coarse powder separator before modification. At the same time, record the coal quality of the coal mill inlet, the ventilation volume of the pulverizing system, the fineness of coal pulverized in the pulverizing system, the current of the coal mill, the current of the pulverizing fan, and the pressure cooker at the inlet and outlet of each equipment in the pulverizing system.

[0055] Step 2 carried out the modification of the coarse powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com