A miniaturized high-precision laser beam pointing stabilization device

A stable device and high-precision technology, which is applied in the field of ultra-precision optical measurement and control, can solve the problems of long optical path, limited beam calibration accuracy, large crosstalk, etc., and achieve the effect of accurate adjustment process, miniaturization and high-precision detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through the examples and accompanying drawings, but the protection scope of the present invention should not be limited by this.

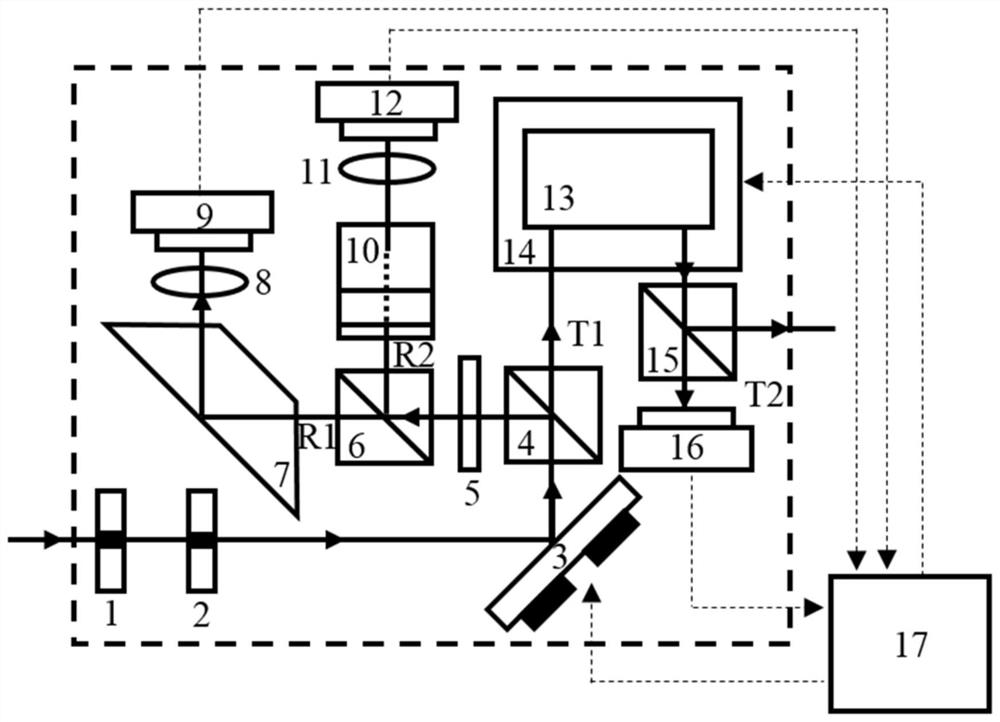

[0026] A miniaturized high-precision laser beam pointing stabilization device, such as figure 1 As shown, it includes: a first adjustable aperture stop 1, a second adjustable aperture stop 2, a two-dimensional fast control mirror 3, a first dichroic prism 4, a half-wave plate 5, a polarizing beam splitter prism 6, The first rhombic prism 7, the first lens 8, the first photoelectric induction device 9, the second rhomboid prism 10, the second lens 11, the second photoelectric induction device 12, the reflective member 13, the nano mobile platform 14, the second light splitter A prism 15, a third photoelectric sensing device 16, and a controller 17. Wherein, the maximum aperture of the first adjustable aperture stop 1 and the second adjustable aperture stop 2 is φ12.0 mm. The reflection c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com