High-efficiency heat exchange type cooling circulating water system and working method thereof

A technology for cooling circulating water and circulating water pumps, which is applied in the types of heat exchangers, water shower coolers, direct contact heat exchangers, etc., which can solve the problems of poor water quality, weaker cooling effect of equipment, and high minimum cooling temperature. Achieve the effect of increasing the ability to purify the air, improving the quality and practicality, and improving the evaporation of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

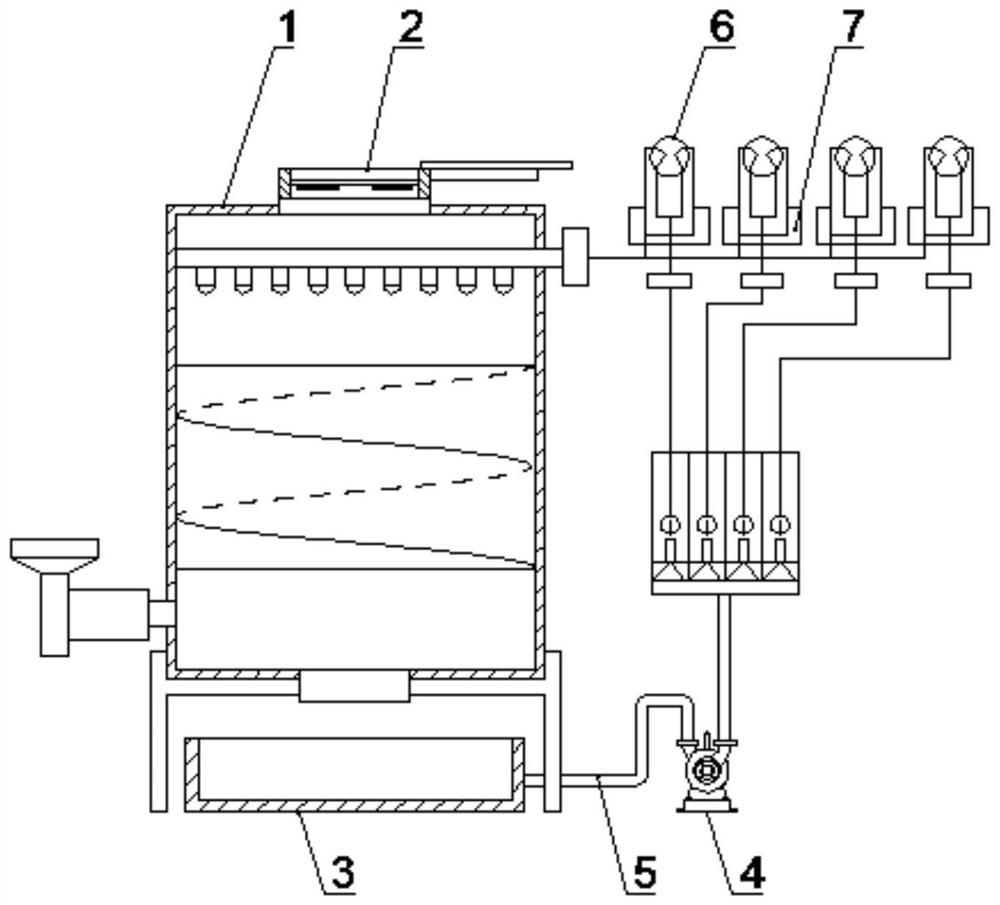

[0030] Such as Figure 1-6 A kind of high-efficiency heat exchange type cooling circulating water system shown includes: cooling tower 1, cooling fan 2, sump 3, circulating water pump 4, water supply pipe 5, condenser 6 and auxiliary cooler 7, described cooling tower A cooling fan 2 is provided on the top of the cooling tower 1, and a sump 3 is provided at the bottom of the cooling tower 1. The sump 3 is connected with a circulating water pump 4, and the output end of the circulating water pump 4 is provided with a water supply pipe 5. The water supply pipe 5 Connected to the cooling tower 1, the water supply pipe 5 is provided with a condenser 6, and the condenser 6 is provided with an auxiliary cooler 7.

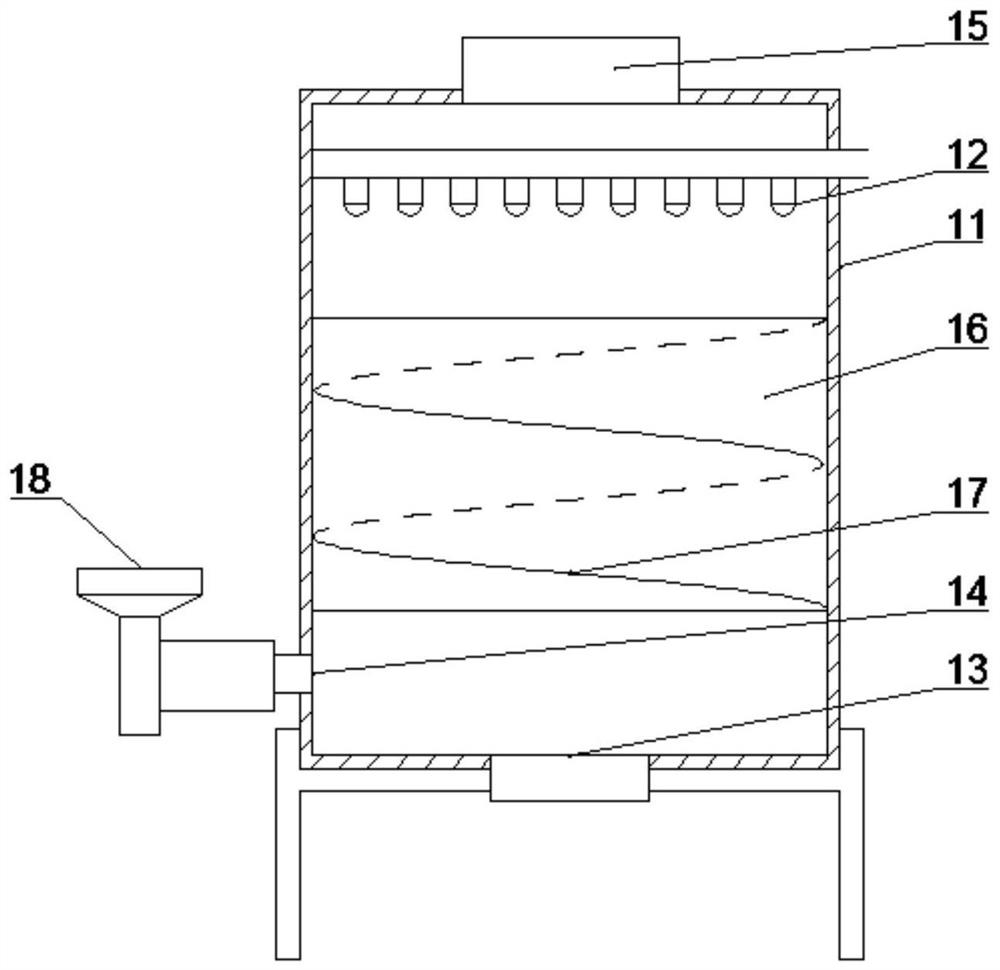

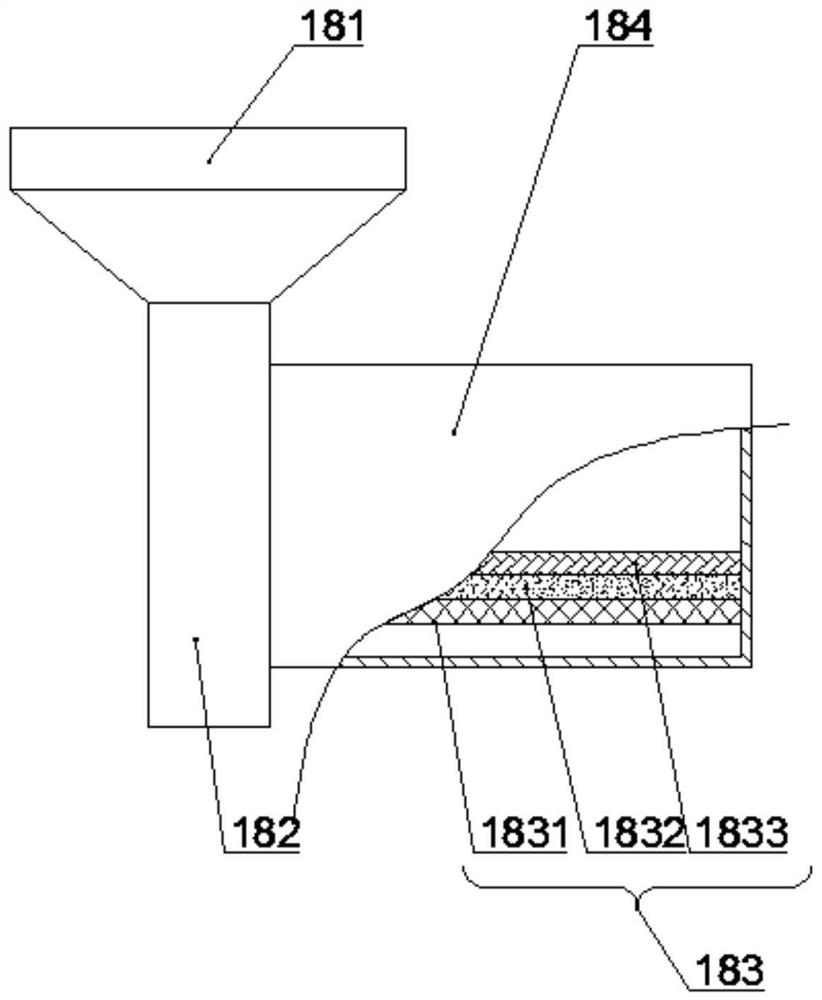

[0031] The cooling tower 1 described in this embodiment includes a tower body 11, a water inlet 12, a water outlet 13, an air inlet 14, an air outlet 15, a filler 16 and a spiral guide plate 17, and the top side of the tower body 11 is provided with an inlet The water inl...

Embodiment 2

[0039] Such as figure 1 A kind of high-efficiency heat exchange type cooling circulating water system shown includes: cooling tower 1, cooling fan 2, sump 3, circulating water pump 4, water supply pipe 5, condenser 6 and auxiliary cooler 7, described cooling tower A cooling fan 2 is provided on the top of the cooling tower 1, and a sump 3 is provided at the bottom of the cooling tower 1. The sump 3 is connected with a circulating water pump 4, and the output end of the circulating water pump 4 is provided with a water supply pipe 5. The water supply pipe 5 Connected to the cooling tower 1, the water supply pipe 5 is provided with a condenser 6, and the condenser 6 is provided with an auxiliary cooler 7.

Embodiment 3

[0041] Such as Figure 1-3 A kind of high-efficiency heat exchange type cooling circulating water system shown includes: cooling tower 1, cooling fan 2, sump 3, circulating water pump 4, water supply pipe 5, condenser 6 and auxiliary cooler 7, described cooling tower A cooling fan 2 is provided on the top of the cooling tower 1, and a sump 3 is provided at the bottom of the cooling tower 1. The sump 3 is connected with a circulating water pump 4, and the output end of the circulating water pump 4 is provided with a water supply pipe 5. The water supply pipe 5 Connected to the cooling tower 1, the water supply pipe 5 is provided with a condenser 6, and the condenser 6 is provided with an auxiliary cooler 7.

[0042] The cooling tower 1 described in this embodiment includes a tower body 11, a water inlet 12, a water outlet 13, an air inlet 14, an air outlet 15, a filler 16 and a spiral guide plate 17, and the top side of the tower body 11 is provided with an inlet The water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com