Gas drainage hole drainage method

A technology for gas drainage and drainage holes, which is applied in the directions of gas drainage, drainage, mining equipment, etc., can solve the problems of inability to timely drainage of drilling holes, frequent actions of automatic water dischargers, and high cost, and achieve low drainage costs and drainage technology. Simple and easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

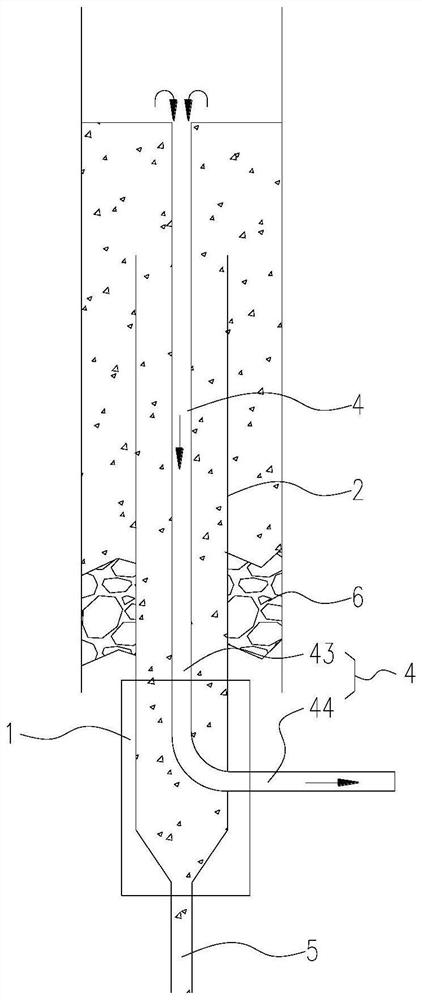

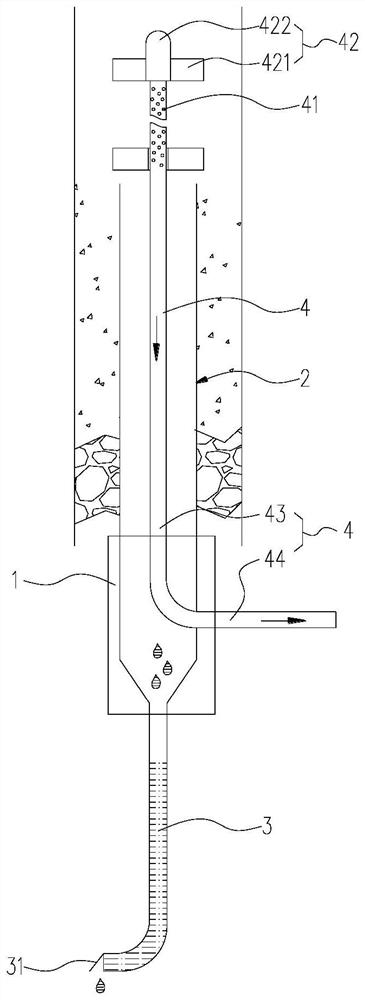

[0040] The gas drainage hole drainage method, step 1, burying the sealing buried pipe 2 in the drainage hole upward;

[0041] Step 2. Assemble the drainage pipe 3 and the exhaust pipe 4 using the connecting device 1 arranged at the bottom of the sealed buried pipe 2:

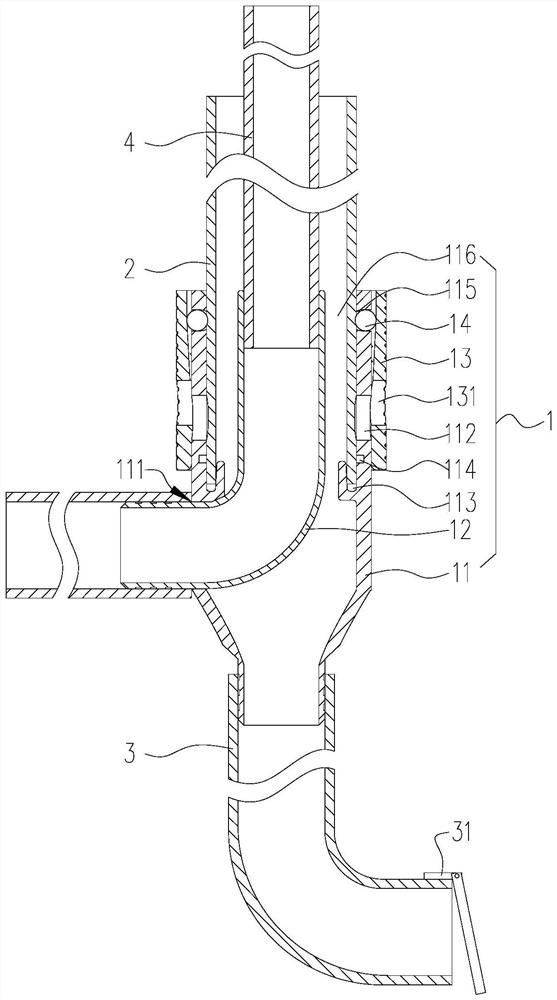

[0042] like figure 2 and image 3 As shown, the connecting device 1 includes an outer tube 11 and an inner tube 12; the two ends of the outer tube 11 are connected, one end is a plug-in end, and the other end is a connecting end; An orifice 111 through which the inner cavity of the tube 11 penetrates radially; the inner tube 12 is L-shaped, one end is a plug-in end, and the other end is a connecting end; the inner tube 12 is plugged into the outer tube 11, An insertion space 116 is provided between the inner wall and the outer wall of the inner tube 12; the insertion end of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com