High-temperature-resistant magnesia carbon brick high-performance antioxidant coating and detection method thereof

A technology of anti-oxidation coatings and magnesia-carbon bricks, applied in the field of materials, can solve problems such as lack of pertinence, few reports, and lack of systematic research, and achieve the effect of convenient use and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

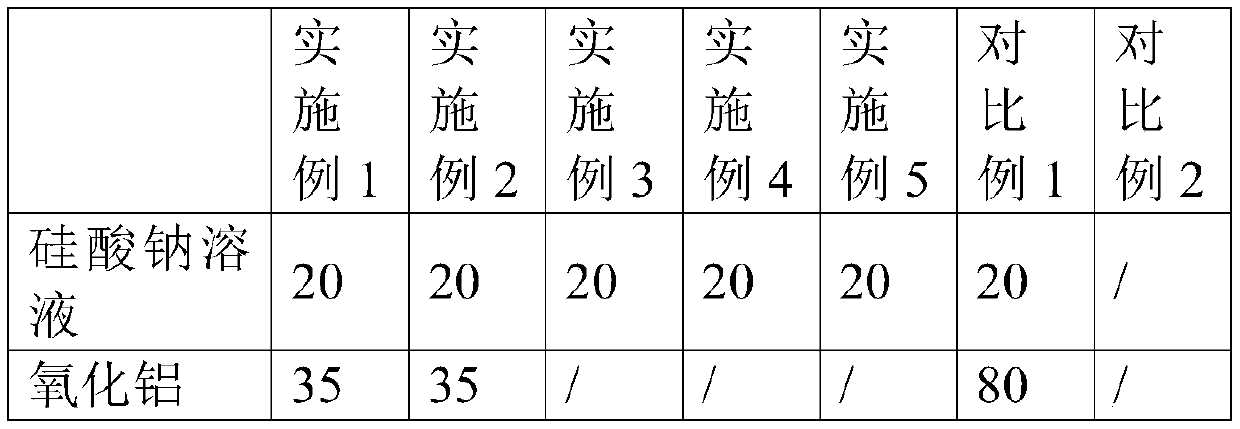

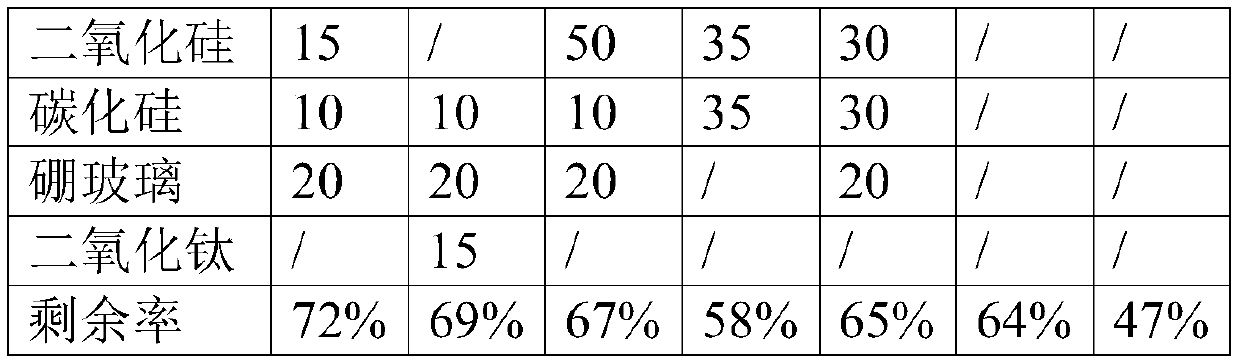

Embodiment 1

[0024] This embodiment provides a high-performance anti-oxidation coating for high-temperature-resistant magnesia-carbon bricks. The raw materials for preparing the high-performance anti-oxidation coating for high-temperature-resistant magnesia-carbon bricks include sodium silicate solution, alumina, silicon dioxide, silicon carbide, and boron glass. and titanium dioxide, and the parts by weight of each component are 20 parts of sodium silicate solution, 0-35 parts of aluminum oxide, 0-50 parts of silicon dioxide, 10-35 parts of silicon carbide, 0-20 parts of boron glass, titanium dioxide 0-15 servings.

Embodiment 2

[0026] This embodiment provides a high-performance anti-oxidation coating for high-temperature-resistant magnesia-carbon bricks. The raw materials for preparing the high-performance anti-oxidation coating for high-temperature-resistant magnesia-carbon bricks include 20 parts by weight of the following components: sodium silicate solution, oxidized 35 parts of aluminum, 15 parts of silicon dioxide, 10 parts of silicon carbide, and 20 parts of boron glass.

Embodiment 3

[0028] This embodiment provides a high-performance anti-oxidation coating for high-temperature-resistant magnesia-carbon bricks. The raw materials for preparing the high-performance anti-oxidation coating for high-temperature-resistant magnesia-carbon bricks include 20 parts by weight of the following components: sodium silicate solution, oxidized 35 parts of aluminum, 10 parts of silicon carbide, 20 parts of boron glass, and 15 parts of titanium dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com