Desulfurized gypsum plaster board with high magnesium ion content and preparation method thereof

A technology for paper-faced gypsum board and desulfurized gypsum, which is applied in the field of desulfurized gypsum paper-faced gypsum board with high magnesium ion content and its preparation, can solve the problems of dehydration and poor adhesion, and achieve good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

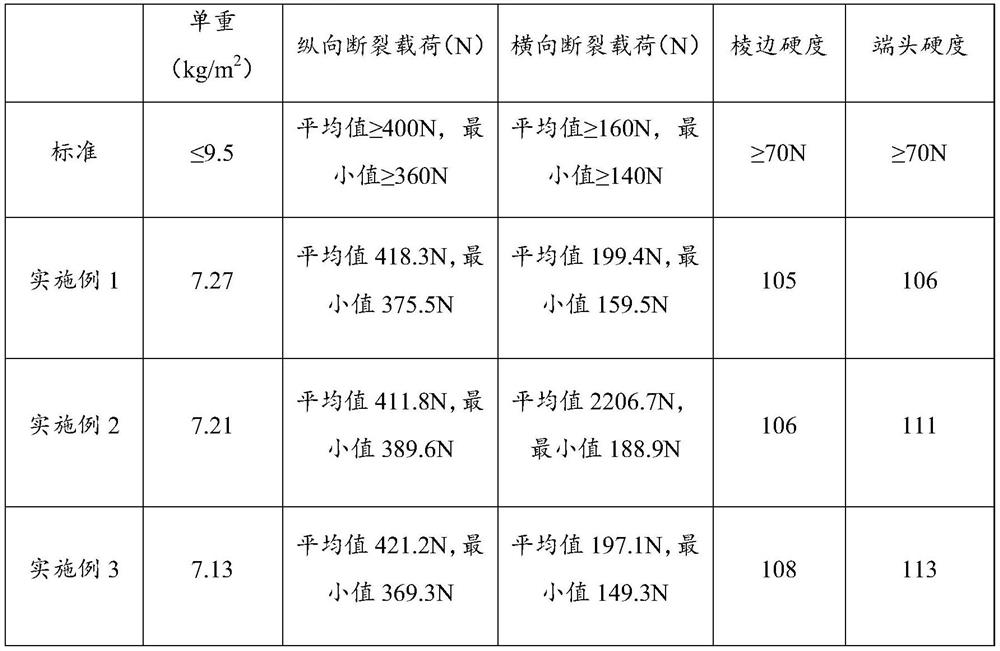

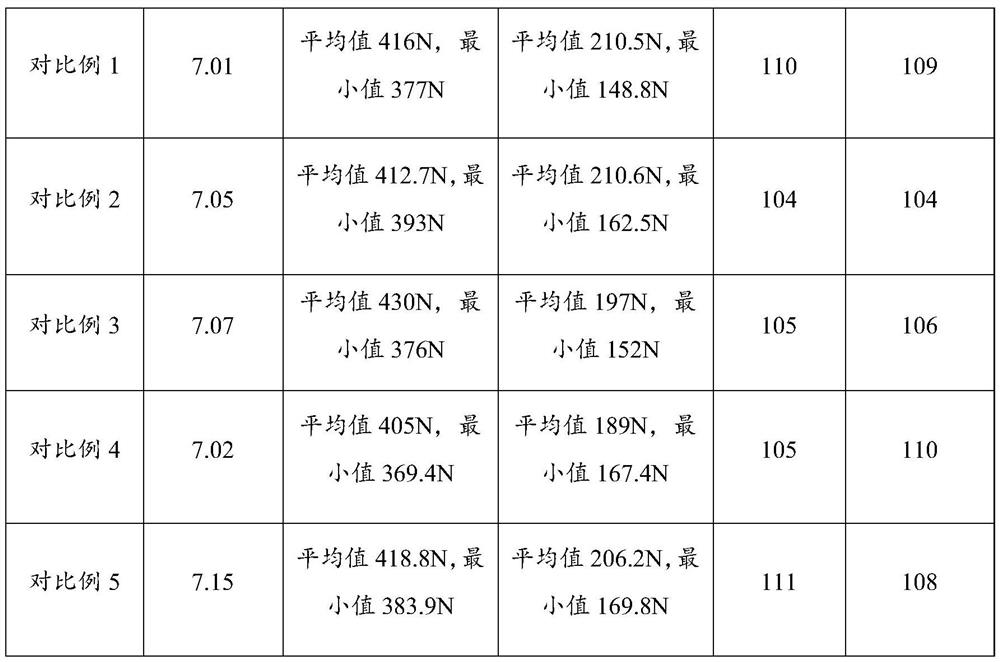

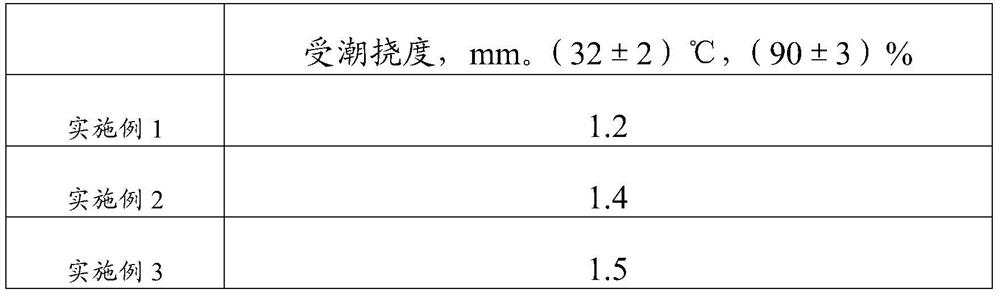

Examples

Embodiment 1

[0044] For the gypsum board prepared in this embodiment, the content of water-soluble magnesium ions in the raw material desulfurized gypsum clinker is 0.19wt.%.

[0045] Prepare the paper-faced gypsum board, the specific steps are as follows:

[0046] Step 1. Pretreat the zeolite and activate it. The method is as follows: the zeolite is roasted at 300° C. for 2 hours in a horse boil furnace, the organic matter is removed, and cooled to room temperature; the zeolite is rinsed 10 times with deionized water, and the volume of the deionized water used is not less than the volume of the zeolite 10 times, 45 ℃ vacuum drying to constant weight.

[0047] Step 2, weighing 100 parts by weight of desulfurized gypsum clinker, 1.05 parts by weight of pretreated zeolite, 0.06 parts by weight of medium-alkali glass fiber (glass fiber length is 9 mm, fiber monofilament diameter is 10 μm), mechanically stirred, and mixed uniformly, A mixture is prepared.

[0048] Step 3: Weigh 60 parts by w...

Embodiment 2

[0054] The content of water-soluble magnesium ions in the raw material desulfurized gypsum clinker of the paper-faced gypsum board prepared in this example is 0.86wt.%.

[0055] Prepare the paper-faced gypsum board, the specific steps are as follows:

[0056] Step 1. Pretreat the zeolite and activate it. The method is as follows: the zeolite is roasted at 300° C. for 2 hours in a horse boil furnace, the organic matter is removed, and cooled to room temperature; the zeolite is rinsed 10 times with deionized water, and the volume of the deionized water used is not less than the volume of the zeolite 10 times, 45 ℃ vacuum drying to constant weight.

[0057] Step 2, weighing 100 parts by weight of desulfurized gypsum clinker, 4.10 parts by weight of pretreated zeolite, 0.18 parts by weight of non-alkali glass fiber (the length of the glass fiber is 15 mm, and the diameter of the fiber monofilament is 15 μm), mechanically stirred, and mixed uniformly. A mixture is prepared.

[00...

Embodiment 3

[0061] The paper-faced gypsum board prepared in this embodiment has a water-soluble magnesium ion content of 1.56 wt.% in the raw material desulfurized gypsum clinker.

[0062] Prepare the paper-faced gypsum board, the specific steps are as follows:

[0063] Step 1. Pretreat the zeolite and activate it. The method is as follows: the zeolite is roasted at 300° C. for 2 hours in a horse boil furnace, the organic matter is removed, and cooled to room temperature; the zeolite is rinsed 10 times with deionized water, and the volume of the deionized water used is not less than the volume of the zeolite 10 times, 45 ℃ vacuum drying to constant weight.

[0064] Step 2: Weigh 100 parts by weight of desulfurized gypsum clinker, 6.7 parts by weight of pretreated zeolite, 0.1 part by weight of alkali-resistant glass fiber (the length of the glass fiber is 12 mm, and the diameter of the fiber monofilament is 12 μm), mechanically stir, and mix uniformly. A mixture is prepared.

[0065] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com