High-sodium-ion-content desulfurized gypsum plaster board and method for improving bonding grade

A technology of gypsum board and desulfurized gypsum, which is applied in the field of desulfurized gypsum plaster board with high sodium ion content, can solve the problems of dehydration and poor adhesion of gypsum board, and achieve good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

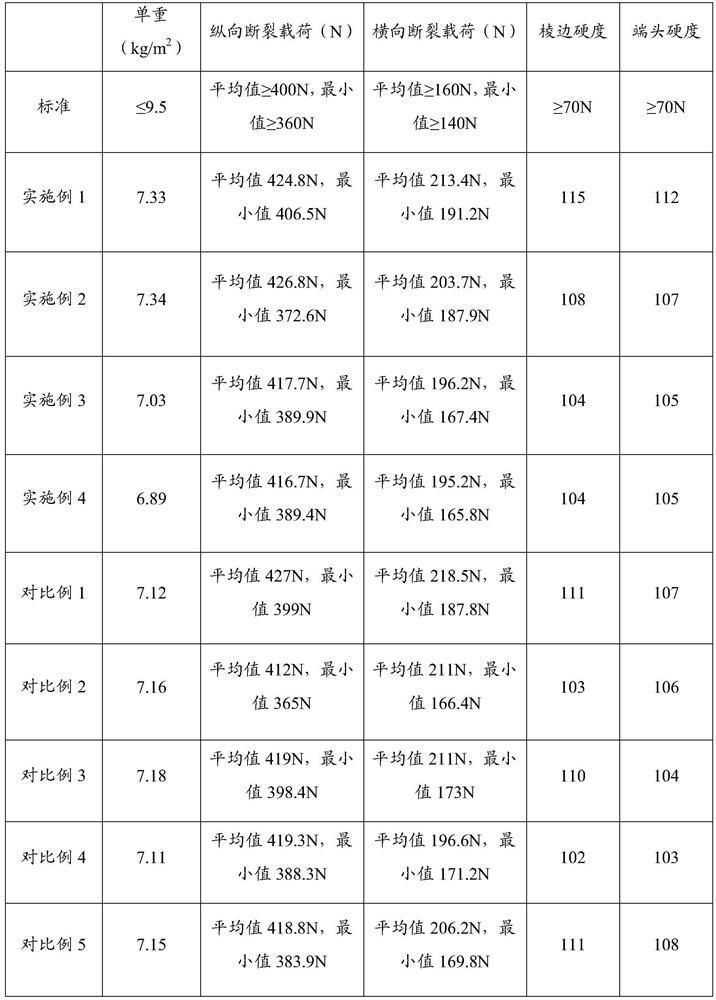

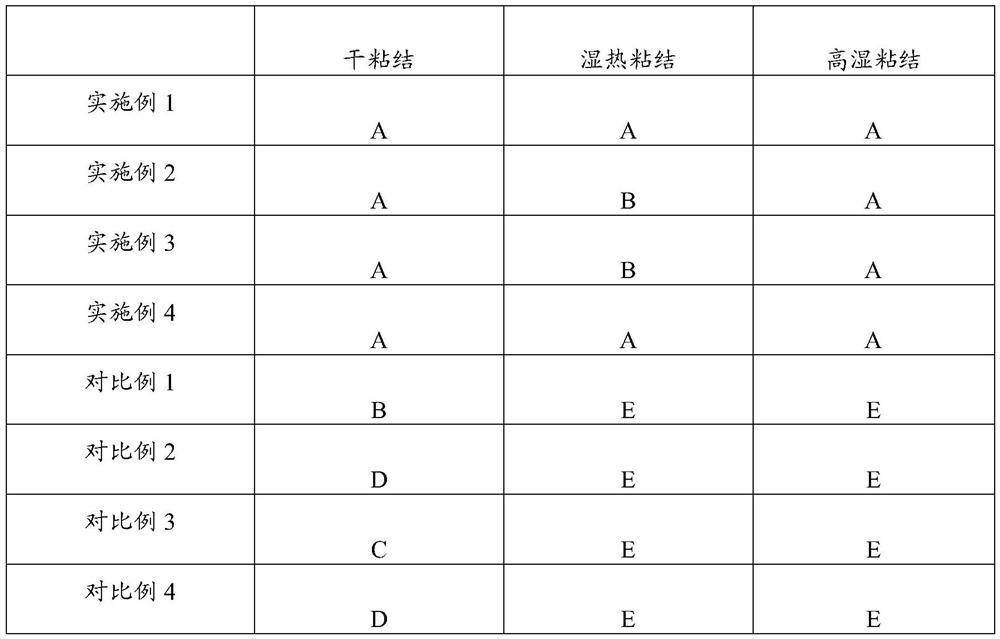

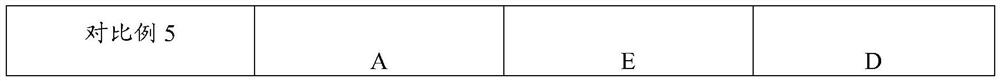

Examples

Embodiment 1

[0044] For the gypsum board prepared in this embodiment, the content of water-soluble sodium ions in the raw material desulfurized gypsum clinker is 0.09 wt.%.

[0045] Prepare the paper-faced gypsum board, the specific steps are as follows:

[0046] Step 1. Pretreat the zeolite and activate it. The method is as follows: the zeolite is roasted at 300° C. for 2 hours in a horse boil furnace, the organic matter is removed, and cooled to room temperature; the zeolite is rinsed 10 times with deionized water, and the volume of the deionized water used is not less than the volume of the zeolite 10 times, 45 ℃ vacuum drying to constant weight.

[0047] Step 2: Weigh 100 parts by weight of desulfurized gypsum clinker, 0.06 parts by weight of medium-alkali glass fiber (the length of glass fiber is 9 mm, and the diameter of fiber filament is 10 μm), stir mechanically, and mix evenly to prepare a mixture.

[0048] Step 3: Weigh 60 parts by weight of water, 1.25 parts by weight of pretre...

Embodiment 2

[0054] The paper-faced gypsum board prepared in this embodiment has a water-soluble sodium ion content of 0.12 wt.% in the raw material desulfurized gypsum clinker.

[0055] Prepare the paper-faced gypsum board, the specific steps are as follows:

[0056] Step 1. Pretreat the zeolite and activate it. The method is as follows: the zeolite is roasted at 300° C. for 2 hours in a horse boil furnace, the organic matter is removed, and cooled to room temperature; the zeolite is rinsed 10 times with deionized water, and the volume of the deionized water used is not less than the volume of the zeolite 10 times, 45 ℃ vacuum drying to constant weight.

[0057] Step 2: Weigh 100 parts by weight of desulfurized gypsum clinker, 0.18 parts by weight of non-alkali glass fiber (the length of the glass fiber is 15 mm, and the diameter of the fiber monofilament is 15 μm), stir mechanically, and mix evenly to prepare a mixture.

[0058] Step 3: Weigh 65 parts by weight of water, 4.2 parts by we...

Embodiment 3

[0061] The paper-faced gypsum board prepared in this embodiment has a water-soluble sodium ion content of 0.16 wt.% in the raw material desulfurized gypsum clinker.

[0062] Prepare the paper-faced gypsum board, the specific steps are as follows:

[0063] Step 1. Pretreat the zeolite and activate it. The method is as follows: the zeolite is roasted at 300° C. for 2 hours in a horse boil furnace, the organic matter is removed, and cooled to room temperature; the zeolite is rinsed 10 times with deionized water, and the volume of the deionized water used is not less than the volume of the zeolite 10 times, 45 ℃ vacuum drying to constant weight.

[0064] Step 2: Weigh 100 parts by weight of desulfurized gypsum clinker, 0.1 part by weight of alkali-resistant glass fiber (the length of glass fiber is 12 mm, and the diameter of fiber monofilament is 12 μm), stir mechanically, and mix evenly to prepare a mixture.

[0065] Step 3: Weigh 72 parts by weight of water, 6.8 parts by weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com