Grinding aid adding method

A grinding aid and grinding technology, which is applied in the field of building materials, can solve the problems of increasing grinding mechanical energy and increasing energy consumption, and achieve the effect of improving grinding efficiency, increasing energy consumption, and good coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The six-chamber ball mill used in the production line is used as the ball milling equipment. The equipment parameters are 0.9m in diameter and 2m in length. The weight ratio of balls with three particle sizes is φ21:φ30:φ35=7:4:1, and the filling rate of grinding media is 26%, rotating speed 23r / min, ball milling time 40min; the grinding aid is solid water reducer FDN-A (provided by Laiwu Huijiang Building Materials Co., Ltd.).

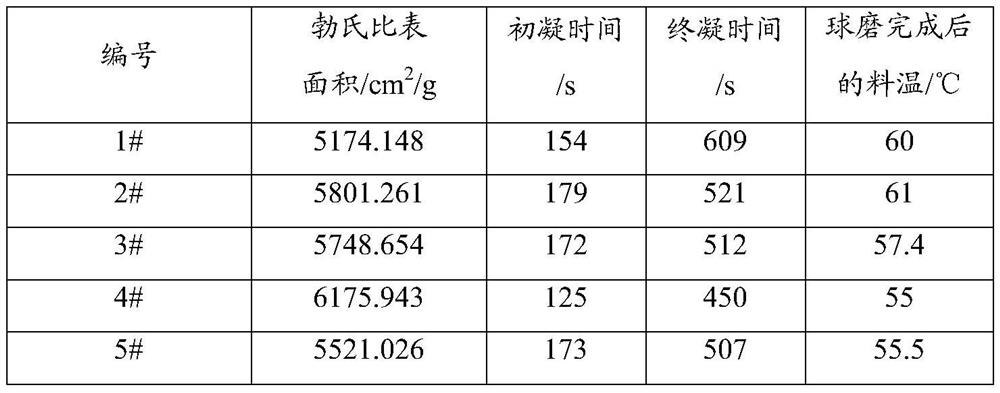

[0024] Make a set of blank control data (1#) and four sets of test data (2# to 5#). No. 1#: Add 50kg of desulfurized gypsum raw meal, and after ball milling for 40min, the Blaine surface area is 5174.148cm 2 / g, the particle size corresponding to the Blaine’s surface area is taken as the target particle size; No. 2#: Add 50 kg of desulfurized gypsum raw meal and 0.5 kg of solid water reducing agent at the same time, and ball mill for 40 minutes; No. 3#: Add 50 kg of desulfurized gypsum raw meal, When ball milling until the Blaine specific surf...

Embodiment 2

[0029] The six-chamber ball mill used in the production line is used as the ball mill equipment. The equipment parameters are 0.9m in diameter and 2m in length. The weight ratio of steel balls with three particle sizes is φ21:φ30:φ35=7:4:1, and the filling rate of grinding media is The grinding aid is 26%, and the rotation speed is 23r / min; starch (edible corn starch, provided by Changchun Dacheng Biotechnology Development Co., Ltd.) is selected as the grinding aid.

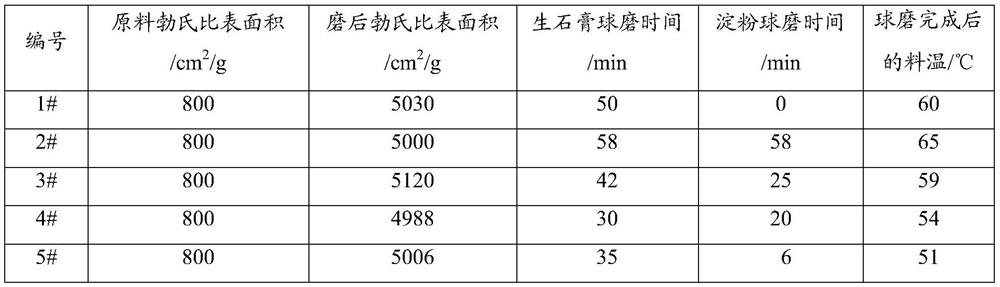

[0030] 1# Add 50kg of desulfurized gypsum raw meal without adding grinding aids, and the Blaine surface area measured after ball milling for 50min is 5030cm 2 / g, the particle size corresponding to the Blaine surface area is used as the target particle size; 2# adds 5kg grinding aid and 50kg desulfurized gypsum raw meal at the same time, and ball mills to about the target particle size; 3# first adds 50kg desulfurized gypsum raw meal, Desulfurization gypsum raw meal mill until the Blaine specific surface area is ...

Embodiment 3

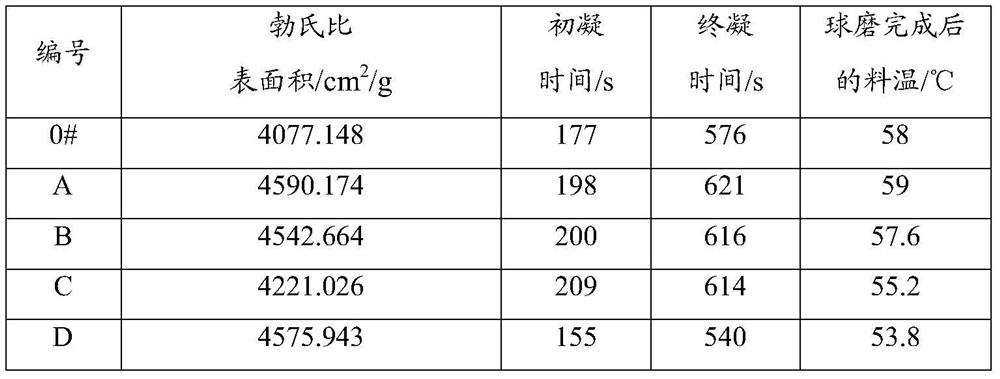

[0034] Use a star-shaped ball mill model QXQM-2 to mill at a speed of 600r / min. The ball mill has 4 ball mill jars in total. Select one of the ball mill jars as 0#, and put 120g of agate balls and 140g of desulfurized gypsum raw meal in it, and measure The Blaine specific surface area of the desulfurized gypsum raw meal is 900cm 2 / g, Blaine specific surface area measured by ball milling for 2h is 4077.148cm 2 / g, as the target particle size; then number 4 ball milling tanks A, B, C, D, put 120g of the same agate balls in each tank, add desulfurized gypsum raw meal, and perform ball milling under the same conditions. Grinding aid selects starch (edible cornstarch, provided by Changchun Dacheng Biotechnology Development Co., Ltd.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blaine specific surface area | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com