Aquaculture waste centrifugal filter pressing device and control method thereof

A technology for aquaculture and waste, applied in chemical instruments and methods, centrifugal separation water/sewage treatment, filtration treatment, etc., can solve the problem of solid waste immobilization and transfer. There is no very effective solution, and solid waste cannot be realized. Problems such as fixation and transfer, long tail water treatment cycle, etc., achieve the effects of solidification transfer, intelligent and easy-to-learn operation methods, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

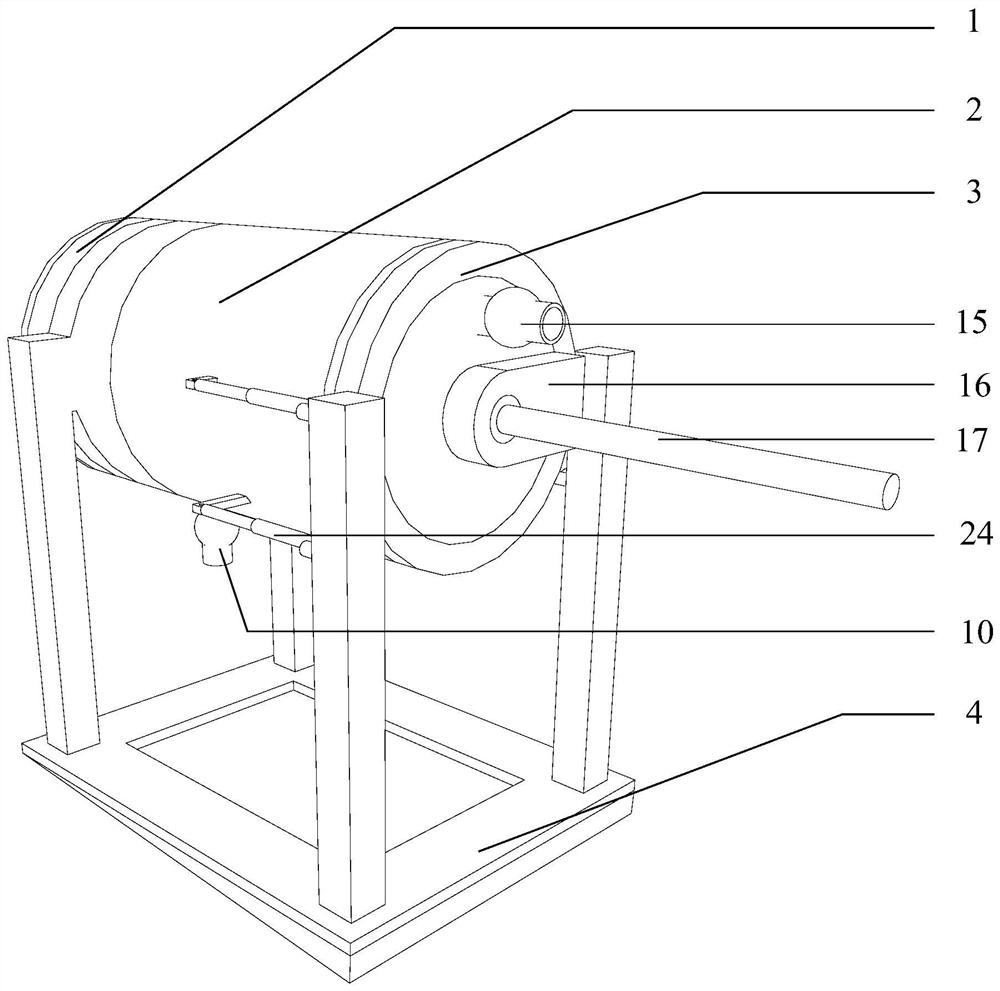

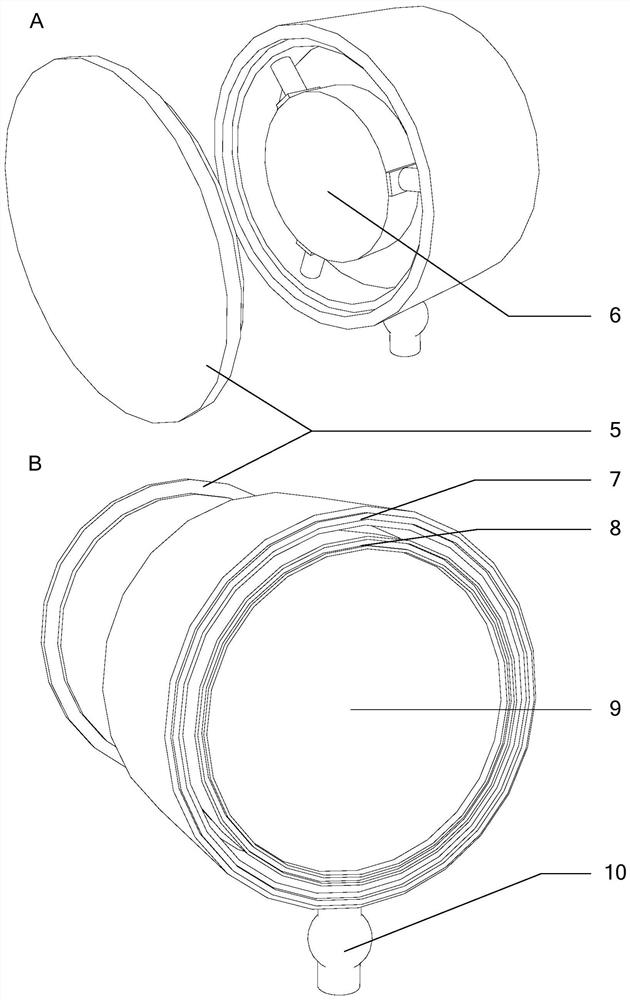

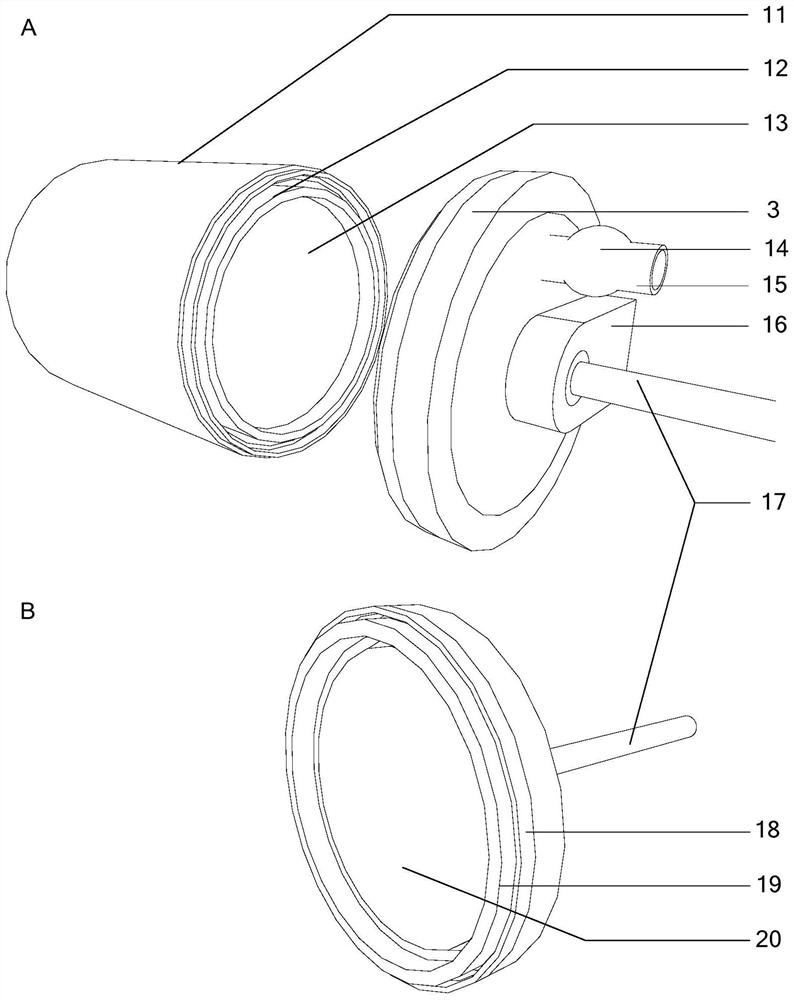

[0025] A centrifugal filter press device for aquaculture waste, the device includes a motor chamber 1, a centrifugal cylinder 2 and a filter press cover 3 arranged on a mounting bracket 4, wherein the motor chamber 1 and the filter press cover 3 are respectively arranged on two sides of the centrifugal cylinder 2 end, and are all sealed and connected with the centrifuge cylinder 2; the motor compartment 1 is formed by a motor compartment bottom cover 5 and a filter press bottom plate 9 to form a sealed compartment body, a DC centrifugal motor 6 is arranged in the compartment body, and a drain pipe 10 is arranged below the compartment body; The pressure filter cover 3 and the centrifuge cylinder 2 are sealed on one side with a filter press top plate 20, and the other side is provided with a water inlet pipe 15, a filter press motor 16 and a filter press screw 17, wherein the filter press motor 16 and the filter press screw 17 are electrically connected to each other. connect.

...

Embodiment 2

[0035] Adopt the device described in embodiment 1 to carry out aquaculture waste centrifugal filter press control, concrete method is as follows:

[0036] S1. Device assembly and fixation and preparation: use expansion bolts to install and fix the installation base 25 on a hard surface, put the motor compartment 1 into the fixing slot of the fixing ring 21 and fix it with screws, and complete the motor compartment 1 Installation; connect the centrifuge cylinder 2 with the pressure filter cover 3, and seal and fix the filter cover-shell sealing connection groove 18 and the filter pressure cover-centrifuge cylinder sealing connection groove 19 with the centrifugal cylinder outer cylinder 11 and the centrifugal cylinder inner cylinder 12 respectively , use screws to connect and fix the pressure filter cover 3 with the centrifugal cylinder 2 to complete the assembly of the centrifugal filter pressure cylinder; use bolts to fasten and connect the four sets of electric push rods 24 t...

Embodiment 3

[0040] Using the device described in Example 1 and the method described in Example 2 to carry out the field application of centrifugal pressure filtration of aquaculture waste:

[0041] Complete the assembly of the device described in Embodiment 1 according to the method described in Embodiment 2, place the device on the hardened level ground, fix the installation base 25 on the ground, and complete the installation and fixation of the device; connect the DC centrifugal motor 6, filter press motor 16, electric Push rod 24, electric ball valve 14 power supply and control cable, start electric push rod 24 elongation, make motor compartment 1 closely connected with centrifuge cylinder 2.

[0042] Put the mud pump into the area where there are many waste deposits in the breeding pond, closely connect the mud pump outlet pipe with the water inlet pipe 15 of the device, open the water inlet electric ball valve 14, start the mud pump to extract the waste at the bottom of the breeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com