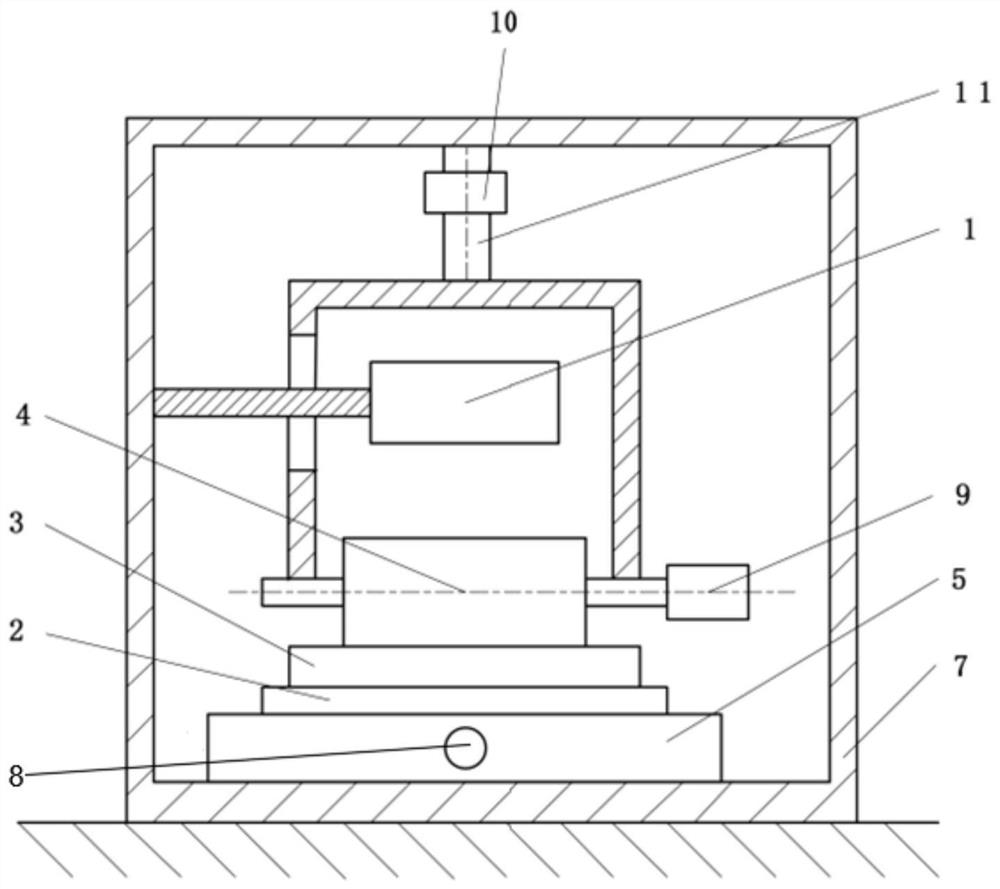

Laser heating roller type micro-imprinting device

A laser heating, roll-forming technology, applied in decorative arts, embossed decorative parts, etc., can solve the problems of low quality of imprinted products, uneven flow filling, high resistance to material deformation, etc., to improve forming stability and forming. Accuracy, good thermal action controllability, good guiding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

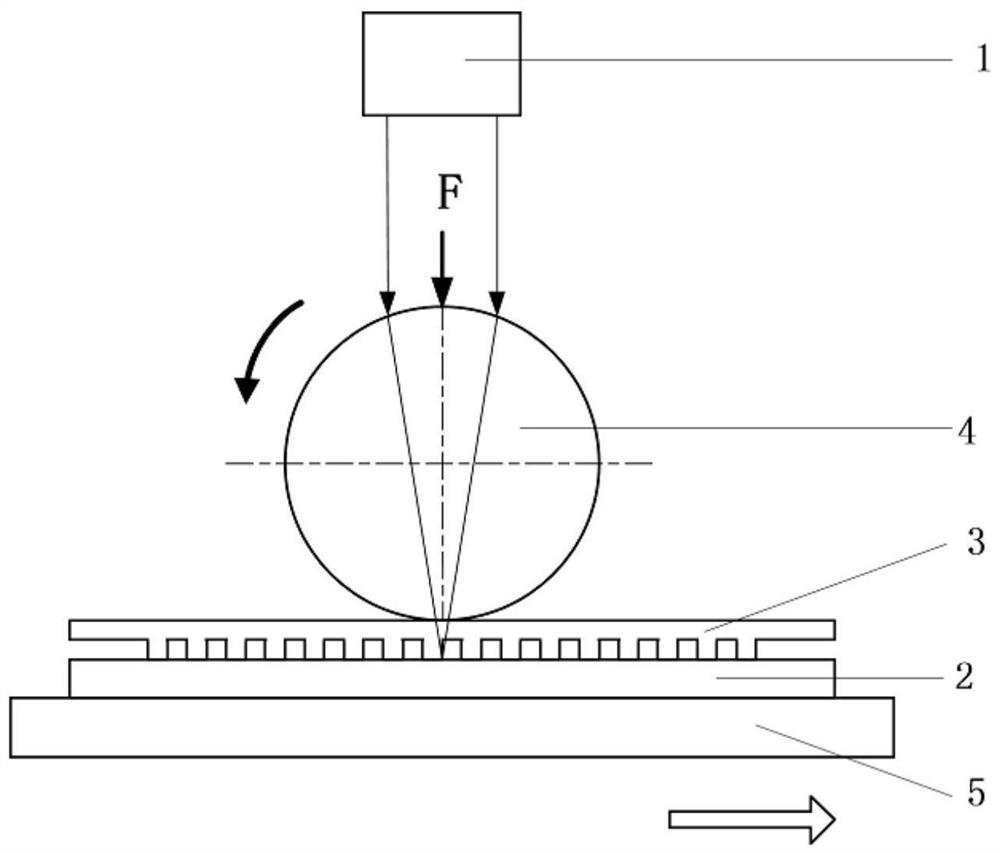

[0041] Such as figure 2 As shown, the transparent mold 3 and the transparent roller 4 are set separately. The transparent mold 3 is a flat mold placed on the upper surface of the material 2. The transparent mold 3 is transported along the support along with the material 2 synchronously. The direction in which the mechanism runs moves, and the translucent roller 4 rolls relative to the upper surface of the translucent mold 3 .

[0042] The supporting transport mechanism is a linear motion platform 5, and the linear motion platform 5 is driven by the first driving mechanism 8 to perform linear reciprocating motion. The linear motion platform 5 can adopt sliding guide rails, rolling guide rails, hydraulic guide rails, air-floating guide rails or magnetic levitation guide rails. Any one of them, the first driving mechanism 8 is a servo motor or a linear motor.

[0043] In this embodiment, when material 2 is embossed with a laser heating roller, the steps are as follows:

[0044] ...

Embodiment 2

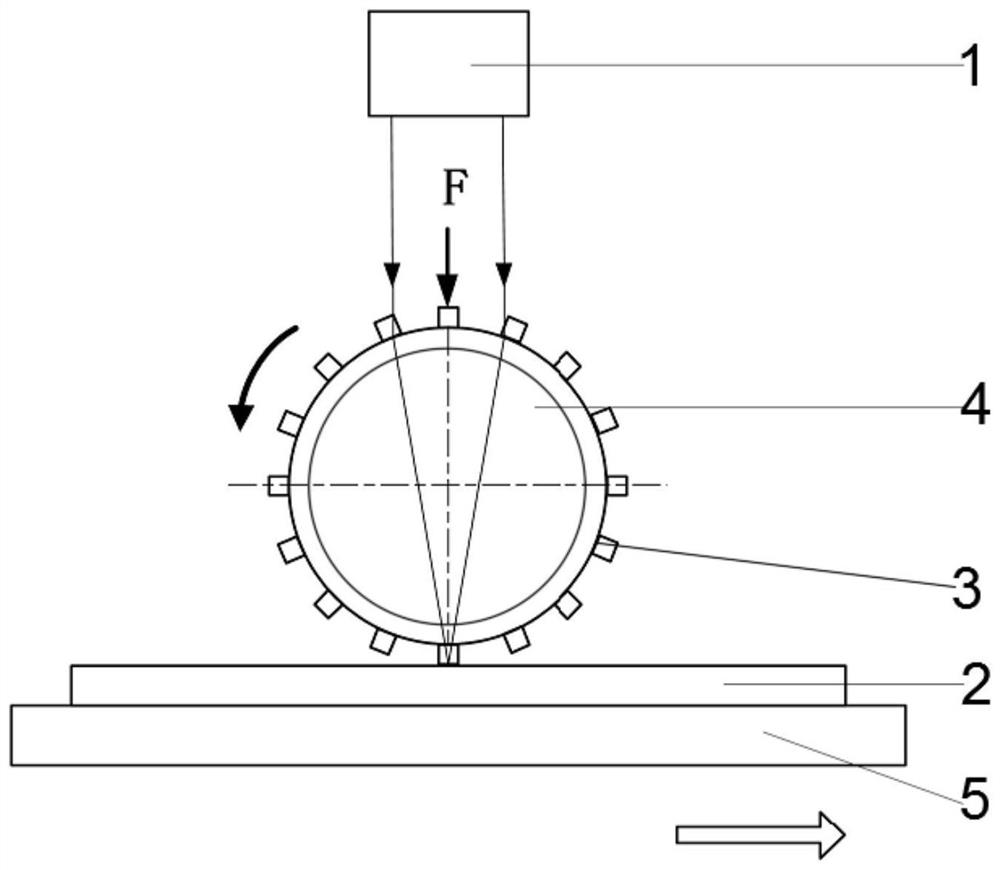

[0050] Such as image 3 As shown, based on Example 1, the light-transmitting mold 3 is replaced, specifically: the light-transmitting mold 3 surrounds the outer roll wall of the light-transmitting roller 4, and is integrally formed with the light-transmitting roller 4. During the rotation of the light roller 4 , the light-transmitting mold 3 on it acts on the surface of the material 2 . Roll embossing has the following steps:

[0051] The first step is to adjust the height of the transparent roller 4, and place the material 2 to be rolled on the linear motion platform 5;

[0052] The second step is to adjust the rolling gap regulator 11, so that the light-transmitting roller 4 moves vertically downward, and the microstructure on the surface of the light-transmitting mold 3 on the outer ring of the light-transmitting roller 4 is pressed into the surface layer of the material 2 to the required rolling depth;

[0053] The third step is to turn on the laser 1, adjust the focal l...

Embodiment 3

[0055] Such as Figure 4 , based on Embodiment 1, the linear motion platform 5 is replaced by a rotating roller 6, that is, the supporting transport mechanism is a rotating roller 6, and the rotating roller 6 is driven to rotate by a first drive mechanism 8, and the rollers of the rotating roller 6 and the light-transmitting roller 4 Shafts are parallel to each other, and the rotating roller 6 is mounted on the frame 7 through a bearing, the bearing is any one of a hydraulic bearing, an air bearing or a magnetic bearing, and the first driving mechanism 8 is a servo motor or a brushless motor , hydraulic motor or air motor in any one. Roll embossing has the following steps:

[0056] The first step is to adjust the height of the light-transmitting roller 4, place the material 2 to be rolled on the rotating roller 6, and place the light-transmitting mold 3 on the top of the material 2, so that the side of the light-transmitting mold 3 with microstructure features is in line with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com