Feeding platform for new material processing and feeding that can be matched with pipe processing equipment

A technology of processing equipment and feeding platform, applied in metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc. To achieve good grinding effect, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

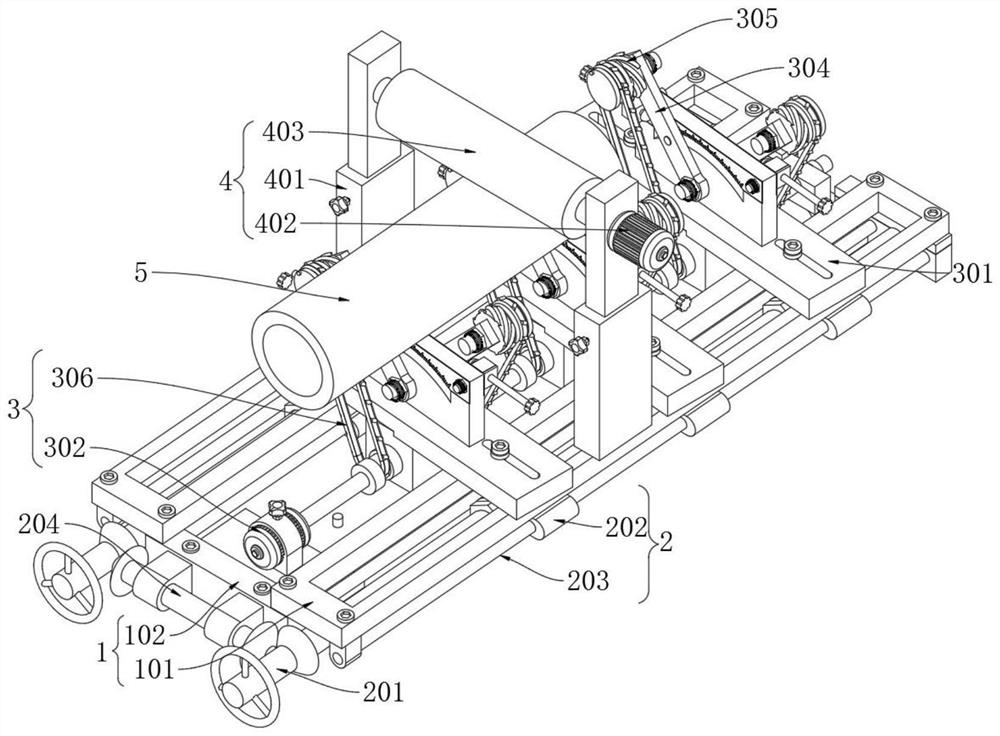

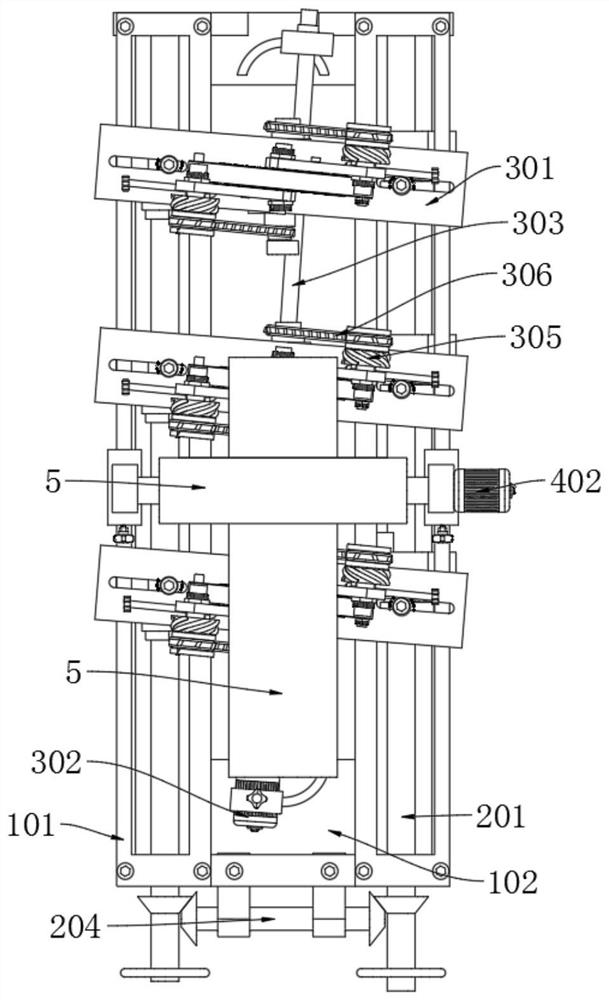

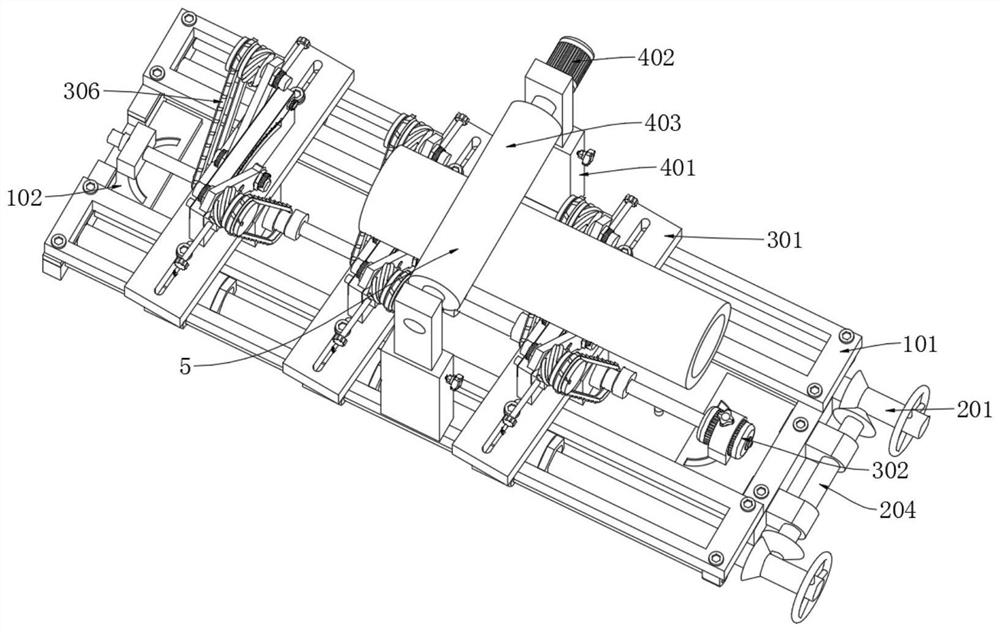

[0043] as attached figure 1 to attach Figure 14 Shown:

[0044] The invention provides a feeding platform for processing and feeding new materials that can be matched with pipe processing equipment, including a fixing mechanism 1; the fixing mechanism 1 is connected with the processing equipment through bolts, and the fixing mechanism 1 is supported by an adjusting mechanism 2 through bolts , the adjustment mechanism 2 is equipped with a rotating handle; the fixing mechanism 1 includes a back-shaped support base 101 and a connecting plate 102, and the back-shaped support base 101 is fixed with two irregular-shaped connecting plates 102 by bolts, and on the connecting plate 102 An arc groove is provided, so that the back-shaped support base 101 cooperates with the connection plate 102 to facilitate the fixing of the adjustment mechanism 2. The arc groove on the connection plate 102 is used to connect the servo motor A302. When the servo motor A302 rotates to adjust the angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com