Vertical metal plate strip friction composite device

A metal strip and composite device technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of increased rolling pressure, deteriorated surface quality of rolled products, and increased roll wear, etc. Lubricity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

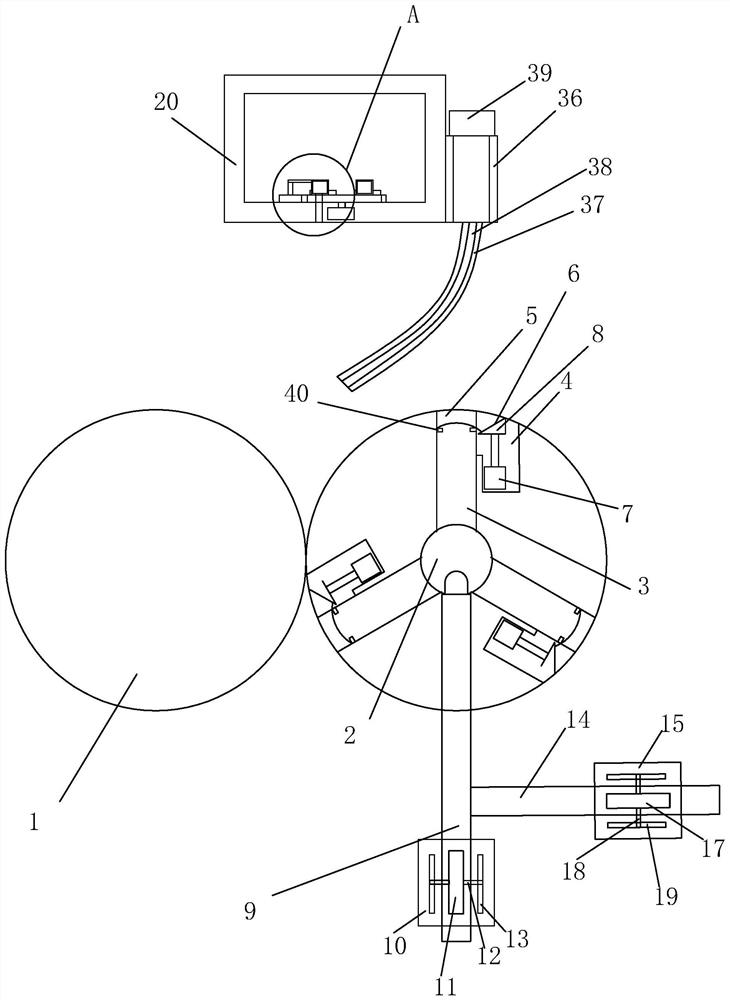

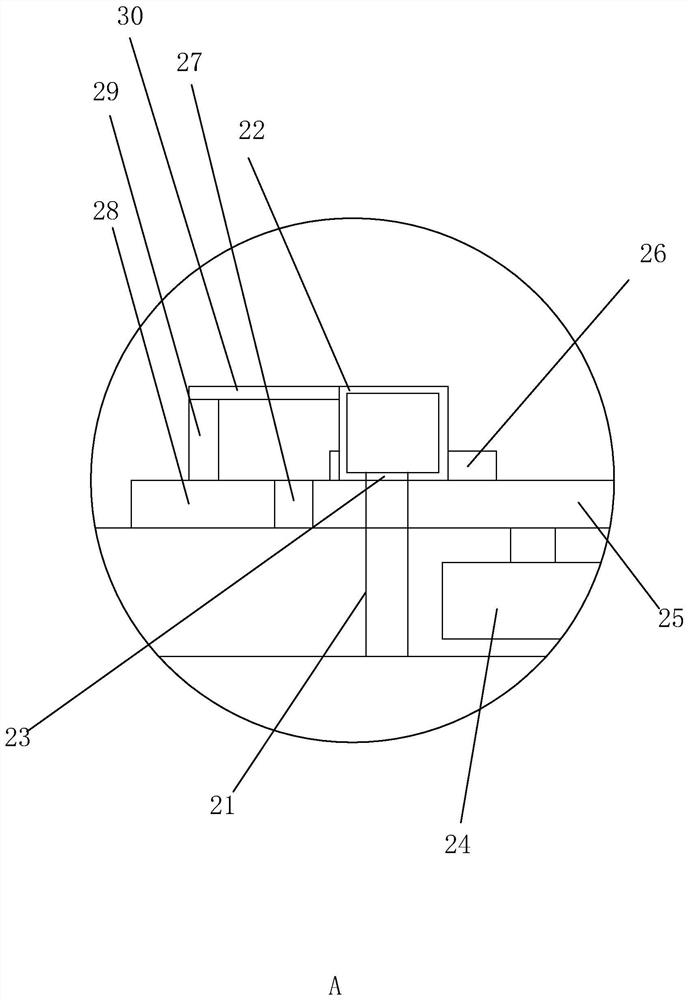

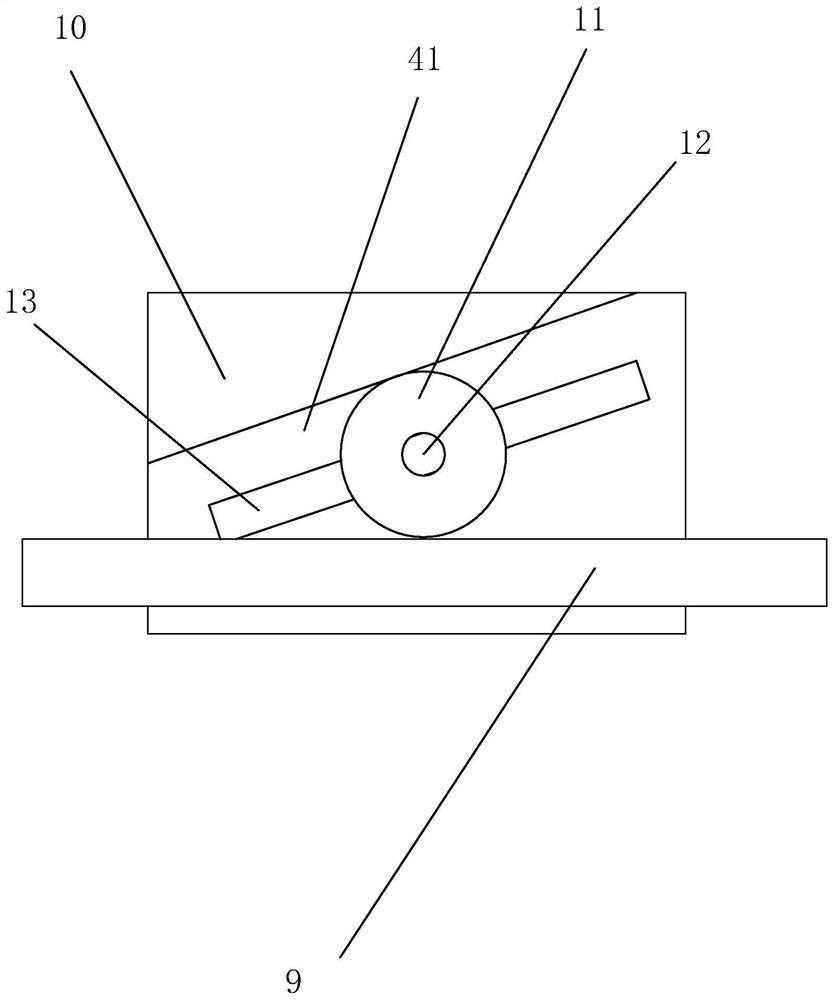

[0035] The present invention will be further described with reference to the accompanying drawings.

[0036] A vertical metal plate belt friction compound device, Figure 1-Figure 9 As shown, two squeeze rollers 1 are included, the two squeeze rollers 1 are arranged horizontally, the middle part of the side of the squeeze roller 1 is provided with a first groove 2, and the inside of the squeeze roller 1 is provided with A plurality of first circulation grooves 3 communicating with the bottom of the first groove 2, each end of the first circulation groove 3 away from the first groove 2 communicates with the outside world, and the squeeze roller 1 is arranged on the first groove 2. One end of a flow groove 3 away from the first groove 2 is provided with a stabilizing groove 4, and the squeeze roller 1 is provided with an arc-shaped plate 5 which is simultaneously in the stabilizing groove 4 and the first flow groove 3, and the arc-shaped plate 5 is used for To close the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com