Cleaning assisting filter

A filter and separator technology, applied in the field of wet smelting purification equipment, can solve problems such as entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

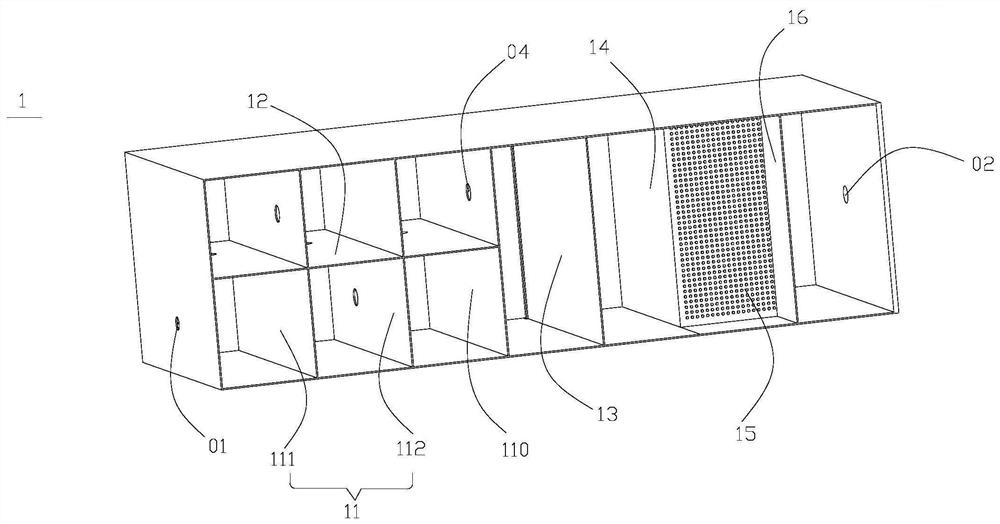

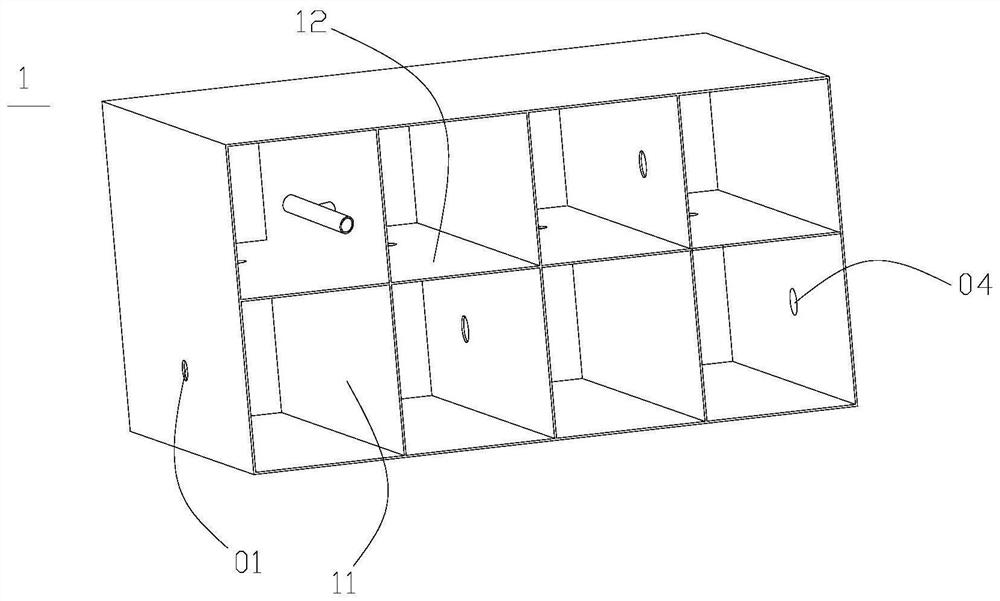

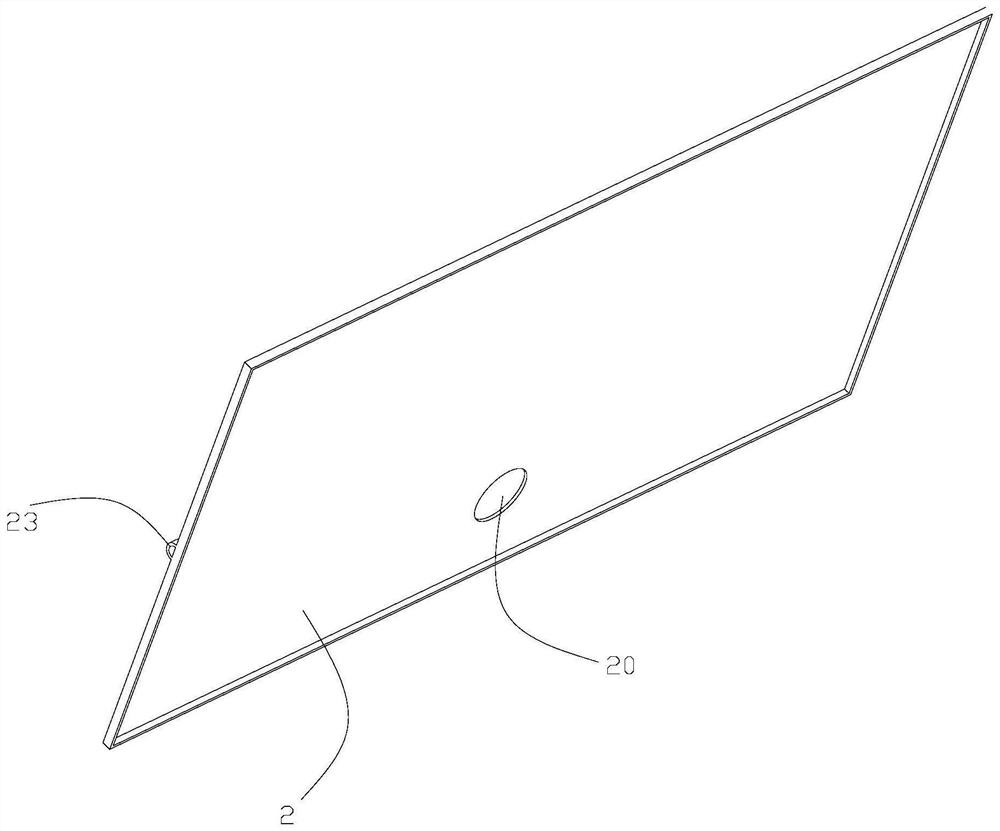

[0050] This embodiment provides a cleaning aid filter, including a box body 1 and a box cover 2, which are arranged on the first material inlet 01 and the first material outlet 02 of the box body 1, and the box body 1 is provided with a first partition 11. The box 1 is separated by a first partition 11 , and the first partition 11 is along the direction of the right side of the box 1 and parallel to the right side of the box 1 . One end of the first partition 11 is fixed on the front side of the box body 1 , and the other end is fixed on the rear side of the box body 1 . The first partition plate 11 is sealed and connected to the bottom of the box body 1 without gaps. The first partition 11 divides the box 1 into a plurality of small boxes A3, and the volume of the small boxes A3 becomes smaller along the material flow direction. The quantity of the first dividing plate 11 is 6, is provided with hole on the first dividing plate 11, and the hole on the first dividing plate 11 i...

Embodiment 2

[0053]This embodiment provides a cleaning aid filter, including a box body 1 and a box cover 2, which are arranged on the first material inlet 01 and the first material outlet 02 of the box body 1, and the box body 1 is provided with a first partition 11. The box 1 is separated by the first partition 11. The first partition 11 is along the direction of the right side of the box 1 and parallel to the right side of the box 1. The number of the first partitions 11 is 10. Along the material flow direction, the first partition 11 close to the direction of the first feeding port 01 is the first first partition 111 , and so on is the second first partition 112 to the tenth first partition. The casing 1 is provided with a second partition 12, the casing 1 is separated by the second partition 12, the second partition 12 is along the direction of the front side of the casing 1, the number of the second partition 12 is one, and the second partition 12 One end of two dividing plates 12 is...

Embodiment 3

[0056] Embodiment 3 provides a cleaning aid filter, except for the technical features described below in Embodiment 3, other structures are the same as in Embodiment 1.

[0057] The quantity of the first dividing plate 11 is 3 pieces, and the first piece-the 3rd piece first dividing plate all has 1 hole, and the hole diameter of the hole on the first piece-the 3rd piece first dividing plate is equal, and the third The hole height on the first partition plate is smaller than the hole height of the first feeding port 01, and the hole on the third first partition plate forms the second feeding port 04. There is a tee structure 03 in the box body 1, and the holes on the first partition of the first block to the third block are connected with the tee structure 03. By setting the tee structure 03, the box body with the same area can extend the material flow path. Further strengthen the separation effect of organic phase and water phase. The material enters the middle end 032 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com