Novel solar frame assembly

A solar energy and frame technology, which is applied in the field of new solar frame components, can solve problems such as wrong processing of frame mounting holes and affect the quality of component product installation, increase friction, prevent uneven filling, and realize component production and installation operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

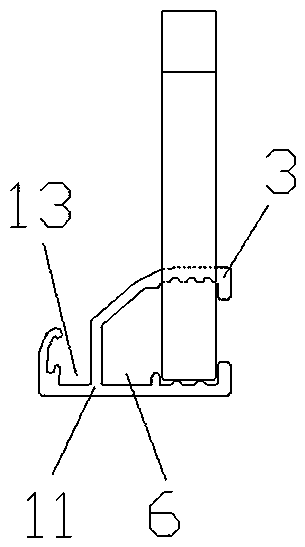

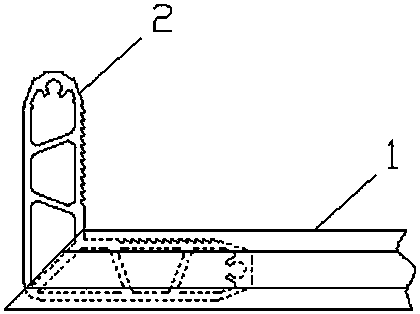

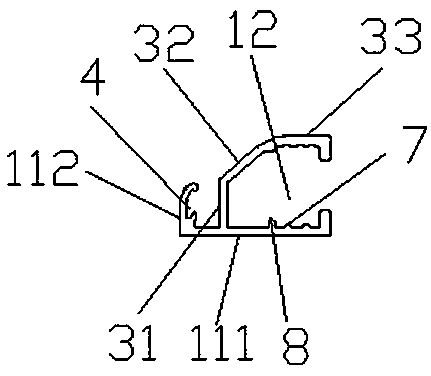

[0021] refer to Figure 1-4 , the present invention provides a new type of solar frame assembly, including a frame assembly 1 and a corner bracket 2, the frame assembly 1 includes a frame piece 11, a sliding cavity 12 embedded in the corner bracket 2, and a card slot 13 for clamping solar energy, the frame piece 11 is composed of a horizontal section 111 and a vertical section 112. The upper end of the horizontal section is vertically provided with a cantilever 3. The cantilever 3 is composed of a vertical section 31, a broken line section 32 and a horizontal section 33. The horizontal section 33 is in phase with the horizontal section 111. Parallel and corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com