A kind of positive electrode active material and its preparation method and lithium secondary battery

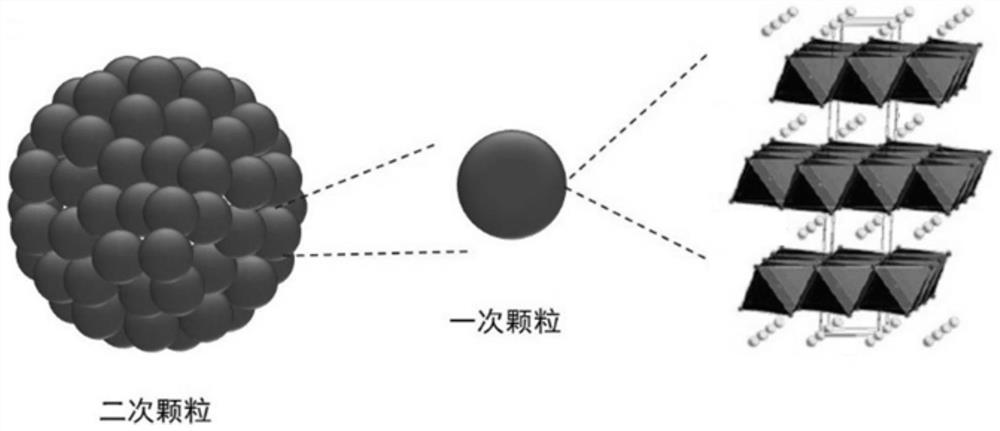

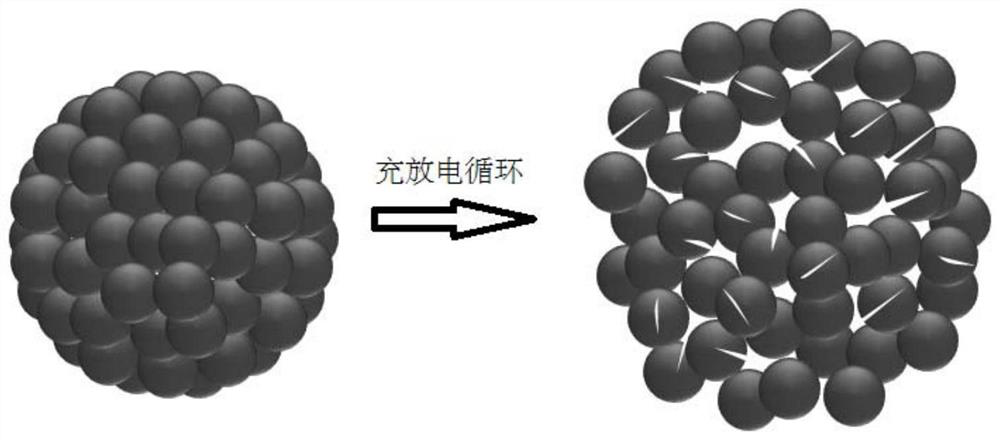

A positive electrode active material and secondary particle technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as uneven lithium deintercalation state, battery capacity attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

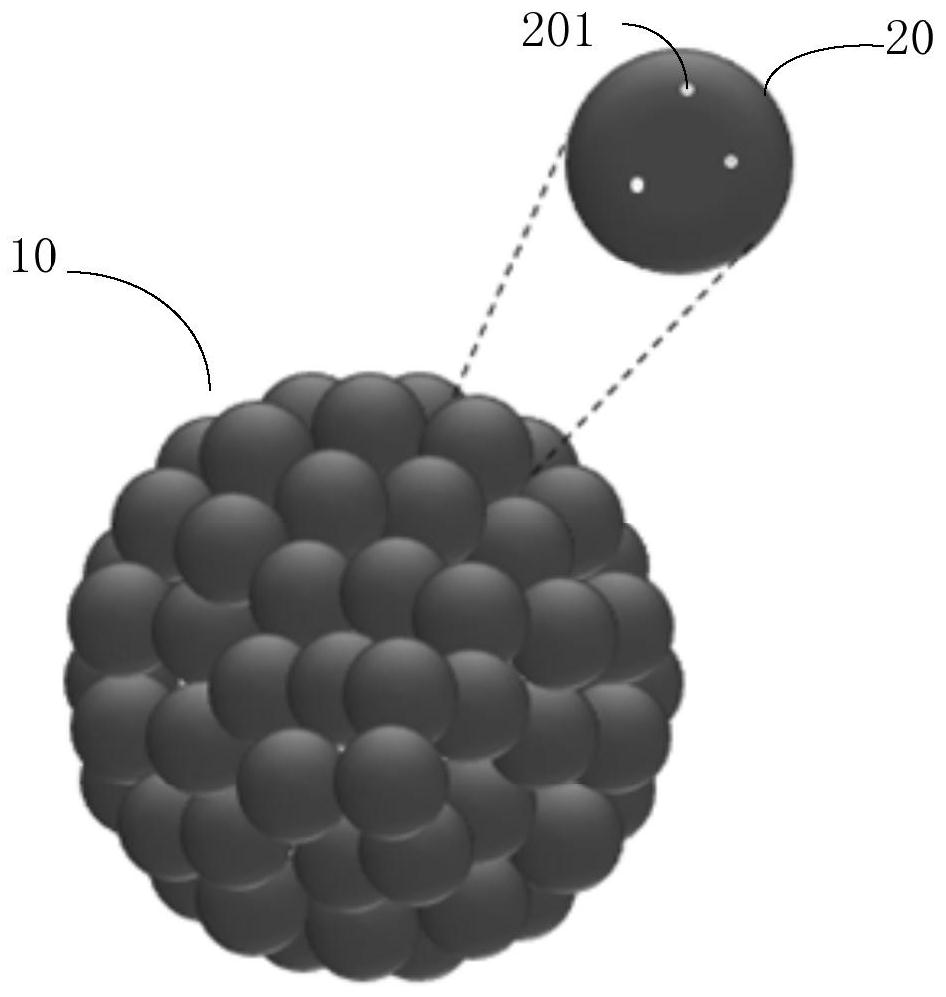

[0048] Correspondingly, an embodiment of the present invention also provides a method for preparing the above positive electrode active material, including the following steps:

[0049] S101. Mix the metal salt and hydrophilic nanoparticles to prepare a mixed solution, so that the hydrophilic nanoparticles are uniformly dispersed in the mixed solution, and the metal ions in the metal salt are in the hydrophilic nanoparticles surface adsorption;

[0050] S102. Add an alkaline material to the mixed solution, make the metal ions use the hydrophilic nanoparticles as nucleation points, and co-precipitate to obtain a positive electrode active material precursor, and the hydrophilic nanoparticles are evenly distributed in the Inside the positive electrode active material precursor;

[0051] S103. Uniformly mix the precursor of the positive electrode active material with the lithium salt, and perform heat treatment in an oxidative atmosphere to obtain the positive electrode active ma...

Embodiment 1

[0067] A kind of nickel cobalt lithium manganese oxide LiNi 0.6 co 0.2 m 0.2 o 2 (NCM622) The preparation method of ternary cathode active material, comprises the steps:

[0068] S101. Add acetylene black with an average particle size of 30nm-45nm into concentrated nitric acid, heat under reflux to 80°C for oxidation treatment for 12 hours, modify the surface of the inert acetylene black with hydrophilic oxygen-containing functional groups, and redisperse in the In water, obtain acetylene black aqueous dispersion liquid, wherein, the concentration of acetylene black nanoparticles is 0.1g / L; Nickel sulfate (NiSO 4 ), cobalt sulfate (CoSO 4 ), manganese sulfate (MnSO 4 ) according to the ratio of molar ratio Ni:Co:Mn=6:2:2 is added in the described acetylene black water dispersion liquid, is configured into the metal salt solution that metal ion total concentration is 2mol / L; And the ammonia of configuration 5mol / L aqueous solution and 10mol / L sodium hydroxide solution;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com