LED display screen module and preparation method thereof

A LED display and LED chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of inconsistent ink color of unit boards/modules, uneven mixing of melanin/powder, uneven color and brightness, etc., to reduce mixing light phenomenon, reduce virtual welding or desoldering or damage, and solve the effect of color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as Figure 1 to Figure 5 As shown, the present embodiment provides a method for preparing an LED display module, the method comprising:

[0046] Such as figure 1 As shown, step 1) is first performed, and the LED display module including the LED chip array is fixed on the jig, and the LED chip array is placed upward.

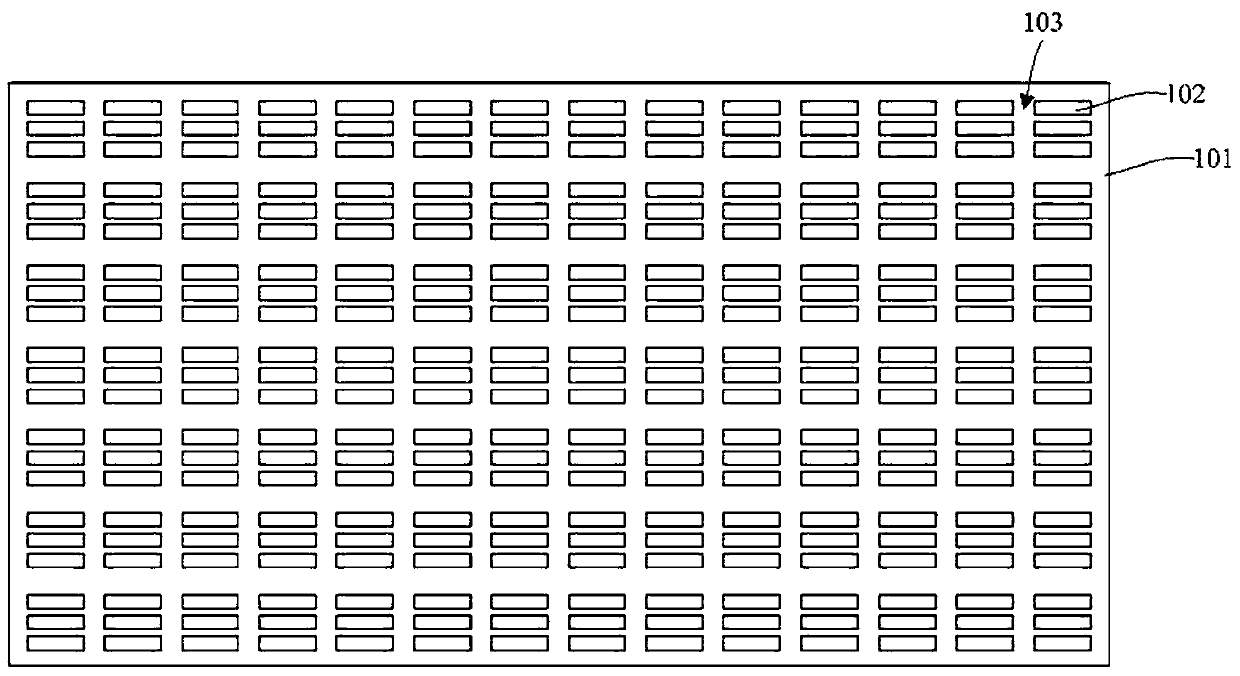

[0047] The LED display module includes: a substrate 101 ; an array of LED chips disposed on the front of the substrate 101 . The substrate 101 may be one of a PCB substrate or a glass substrate. In this embodiment, the substrate 101 is a PCB substrate. The substrate also includes thin film transistors (TFTs). Optionally, there is an electrode array on the front surface of the substrate. Optionally, the back of the substrate is connected to a driver chip and a connector, and the driver chip and connector are arranged on the back of the substrate 101

[0048] The LED chip array includes a plurality of regularly arranged LED chips 102, and the LED...

Embodiment 2

[0079] Such as Figure 7 As shown, this embodiment provides a method for preparing an LED display module, the basic steps of the preparation method are as in Example 1, and the difference from Example 1 is:

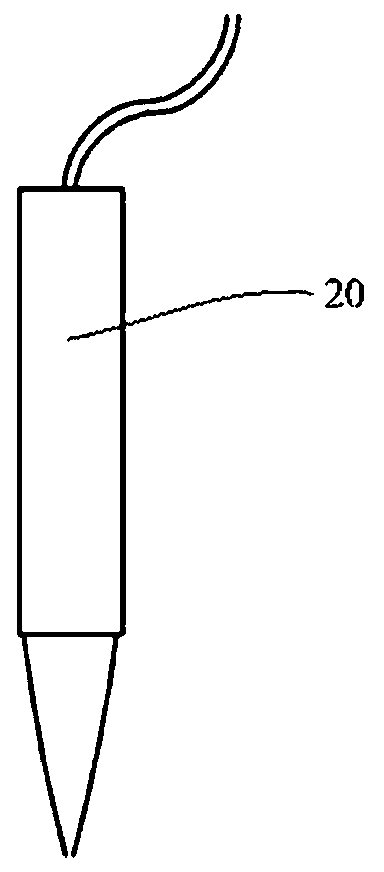

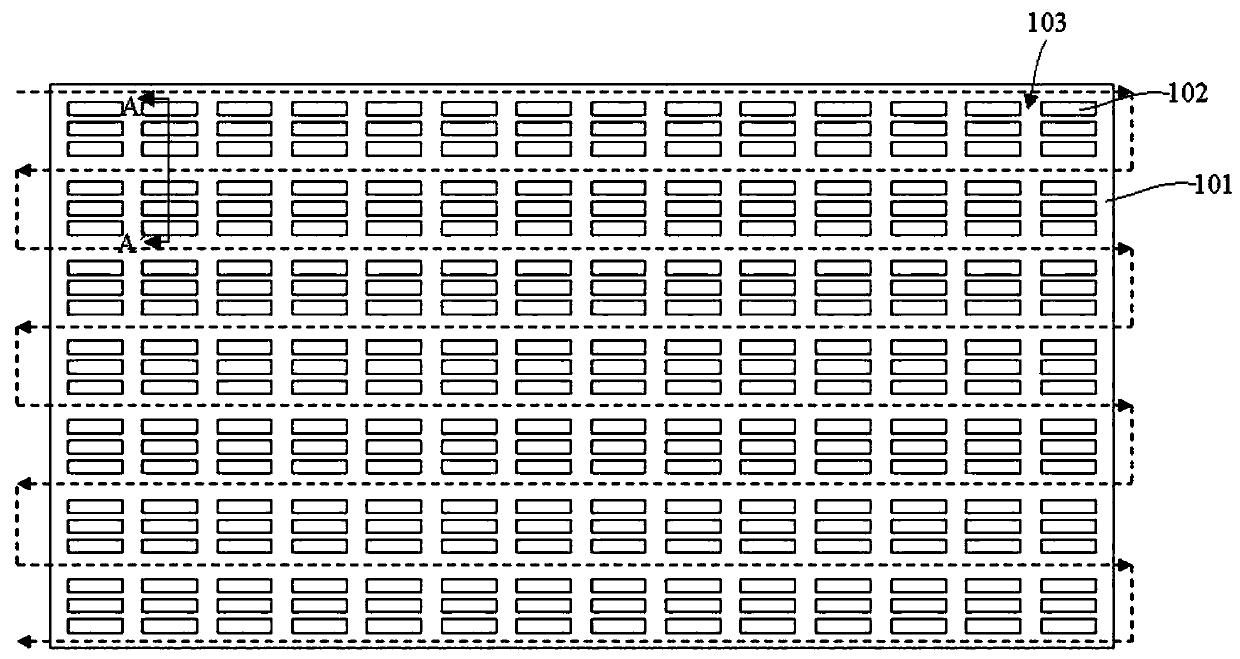

[0080] Step 2) Apply glue on the center line of the gap 103 of the LED chip 102 using a single-needle gluer 20, apply glue longitudinally from one corner of the LED display module substrate to the edge of the other end, and then change the direction by 90° to the other end. For a row of starting points, change the direction by 90° again and apply glue along the dotted line, then apply glue to the following starting points, and apply glue to all partitions in this way.

[0081] This embodiment also provides an LED display module, the difference between the module and Embodiment 1 is:

[0082] The substrate 101 is a glass substrate, and the substrate further includes a thin film transistor (TFT) layer. Optionally, there is an electrode array on the front surface of the subs...

Embodiment 3

[0084] Such as Figure 8 and Figure 9 As shown, this embodiment provides a method for preparing an LED display module, the basic steps of the preparation method are as in Example 1, and the difference from Example 1 is:

[0085] Step 2) Apply glue on the center line of the gap 103 of the LED chip 102 using a multi-needle gluer 30. The gap between the needles of the gluer is consistent with the gap to be glued, as Figure 8 shown. Apply glue from the left side of the LED display module substrate to the edge of the other end, then rotate it 180° downwards, adjust the position to the starting point on the right, apply glue along the dotted line to the left edge of the LED display module, and apply this method cyclically Glue to all partitions like Figure 9 shown.

[0086] In this embodiment, a multi-needle gluing machine is used to apply glue, which can simultaneously apply glue to the gaps 103 of multiple LED chips 102 , which greatly reduces the time required for glue app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com