Method and device for detecting thickness and conductivity of metal coating on surface of metal conductor

A technology for surface metal and metal conductors, applied in electromagnetic measuring devices, measuring devices, electric/magnetic thickness measurement, etc., can solve problems such as accuracy dependence, difficulty in finding another parameter, complex calculation of coil impedance theoretical formula, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

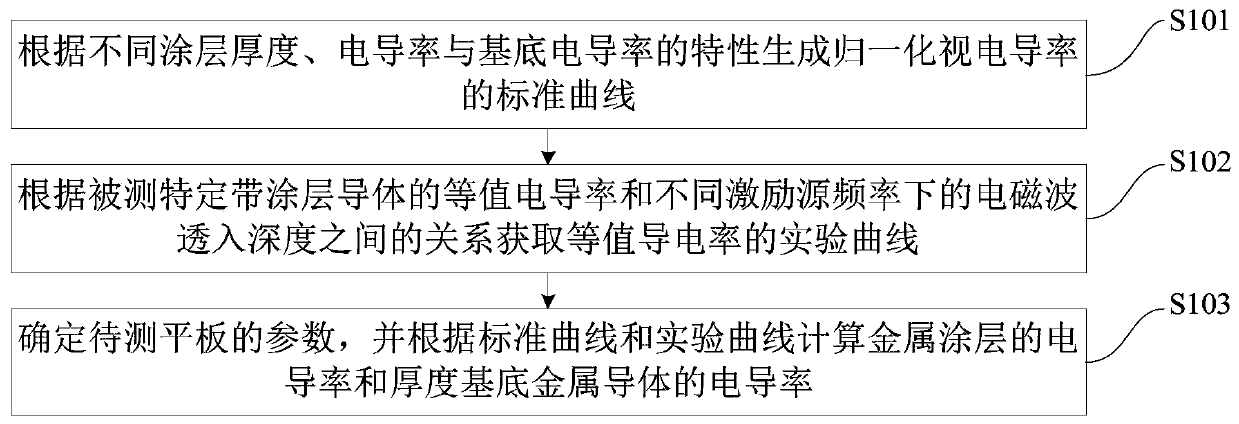

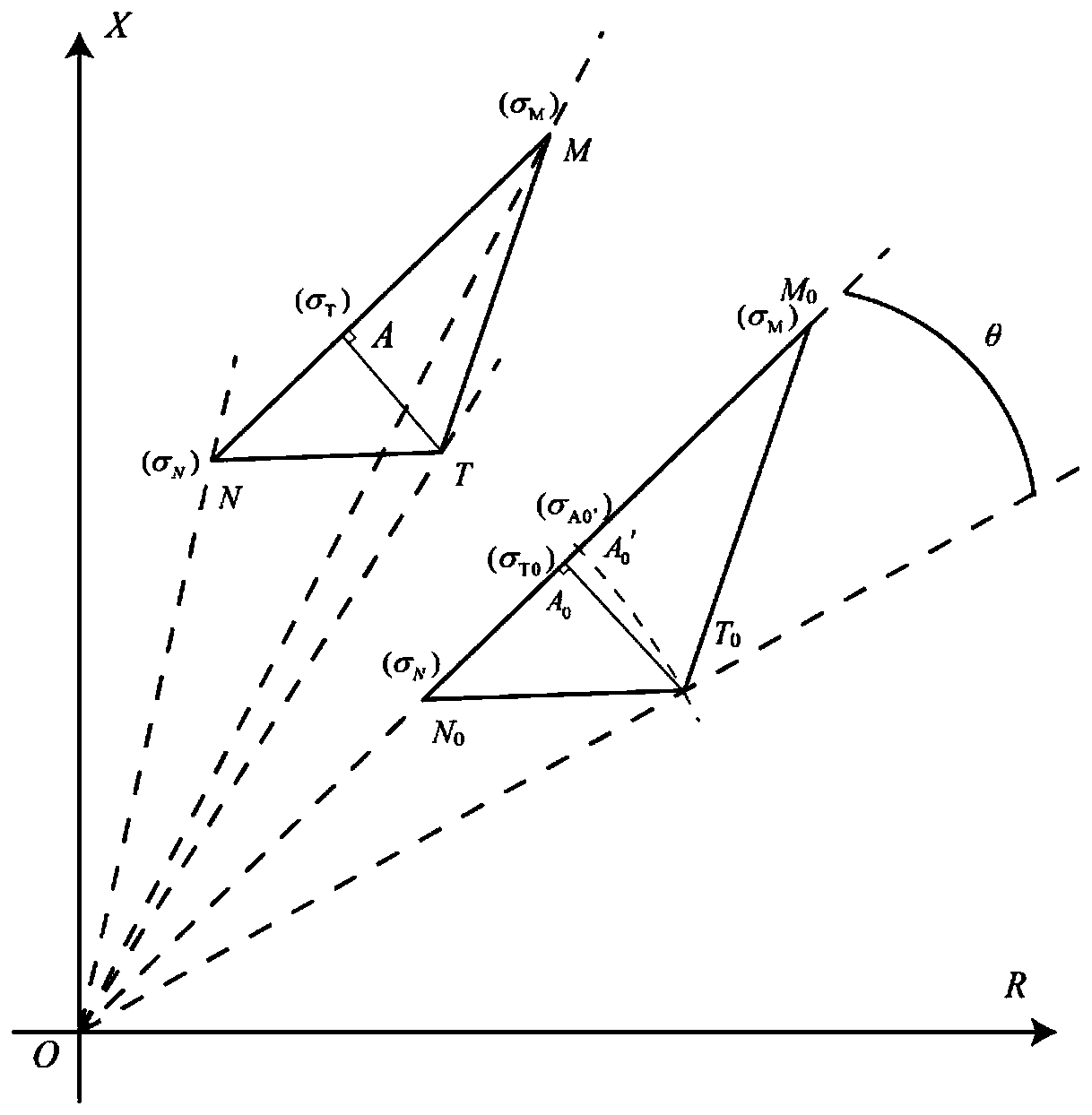

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

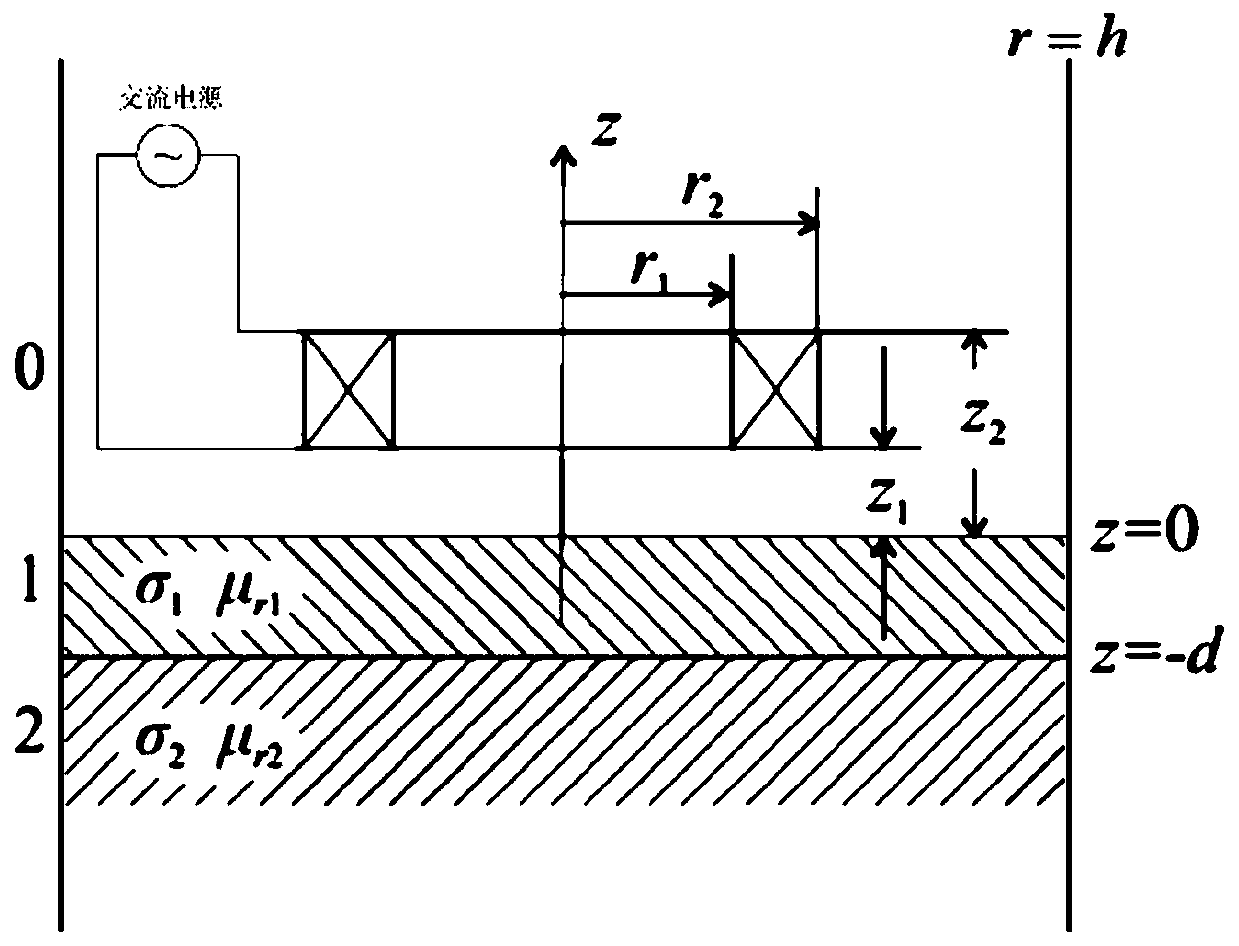

[0044] Coating technology is of great significance for protecting the substrate and improving its high temperature resistance and corrosion resistance, and is widely used in engineering. In the aviation industry, turbine blades are often sprayed with thermal barrier coatings, and the bonding layer is an ultra-thin metal coating; most new concept cars are also being applied with such coatings for surface protection. In order to ensure the safe and reliable operation of such equipment, it is necessary to detect the thickness of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com