Screw drilling tool, vertical drilling tool testing method and well inclination simulation testing equipment

A technology of testing equipment and testing methods, applied in directional drilling, testing of wellbore/well components, mechanical components, etc., can solve the problems of long cycle, high cost, and difficulty in measuring the deviation correction ability of well inclination angle tools, and achieves a reduction in height. requirements, accurate measurement, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Other objects and advantages of the present invention will become clear by explaining the following preferred embodiments of the present application.

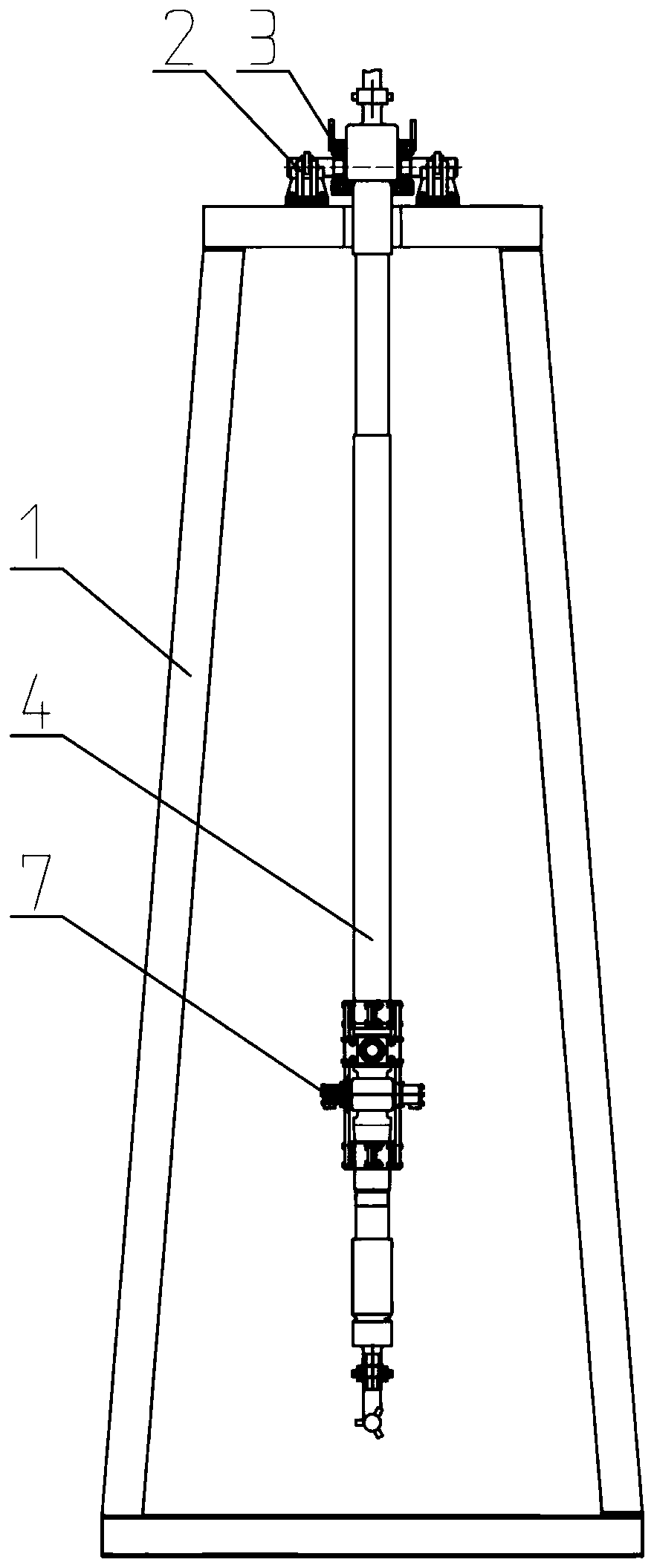

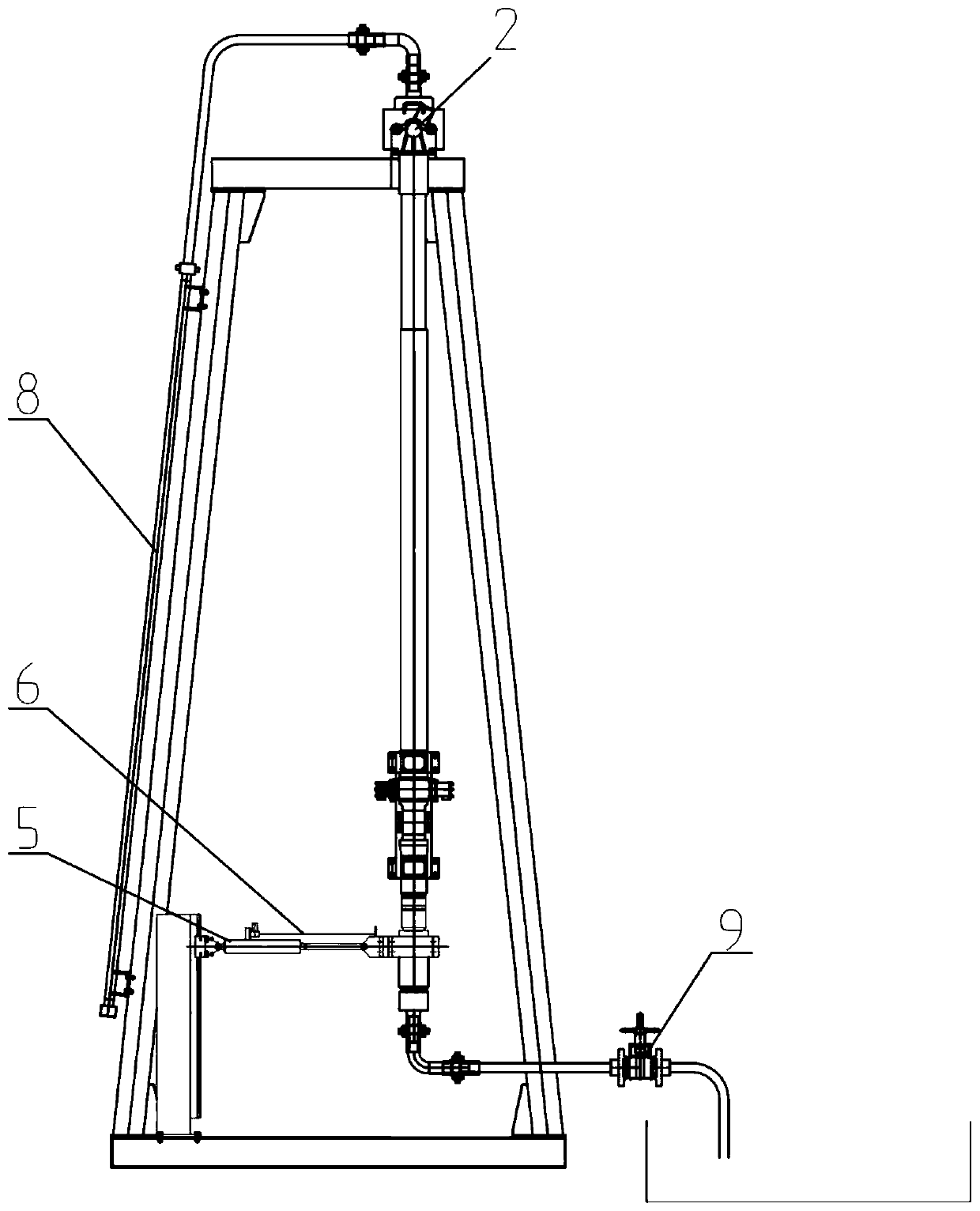

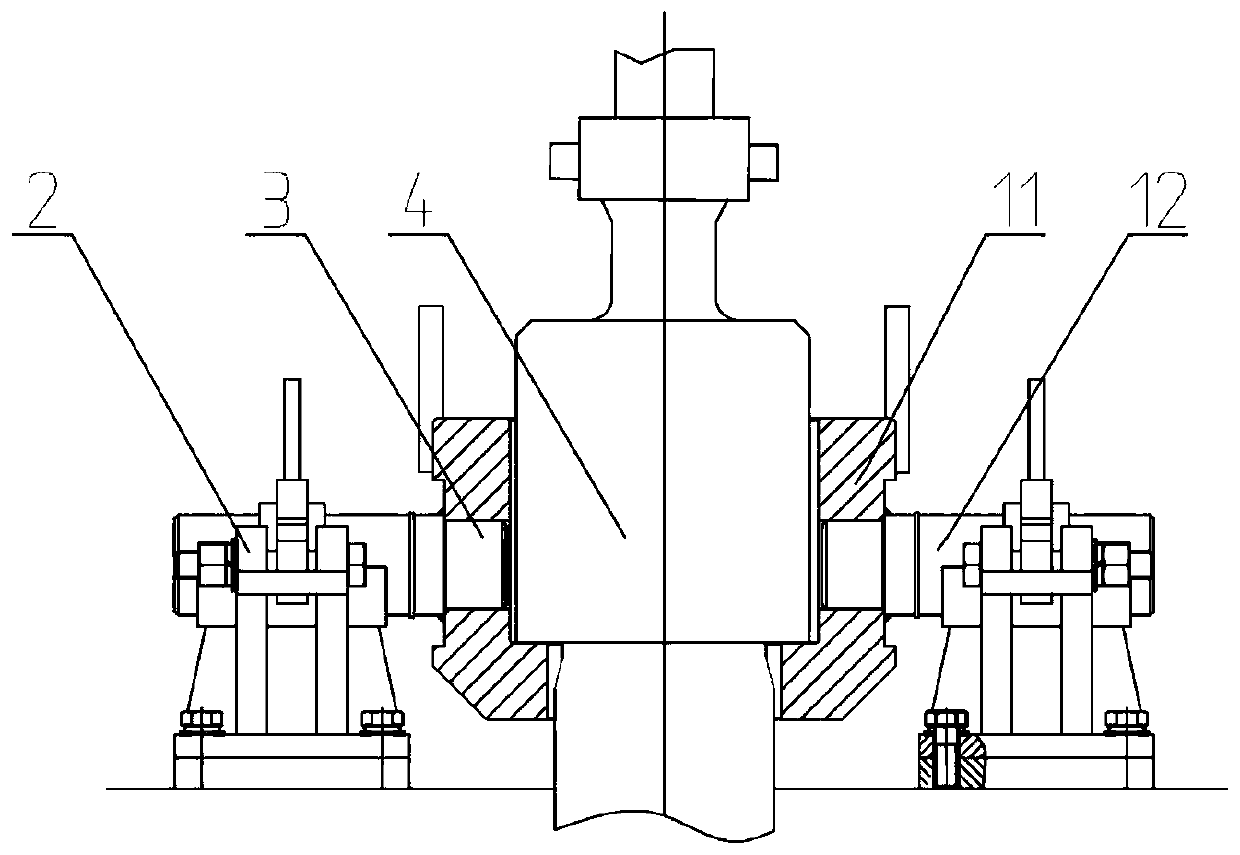

[0059] figure 1 It is a front view of a simulated drilling deviation testing device of the present invention. figure 2 for figure 1 side view.

[0060] Such as figure 1 , figure 2 As shown, a simulated well deviation test equipment includes a main support 1 , a push-pull device 5 and an angle measurement device 6 . Wherein, the first end of the tool under test 4 is pinned to the main bracket 1 . One end of the push-pull device 5 is connected to the main support 1 , and the other end is connected to the measured tool 4 . The push-pull device 5 is used to push or pull the tested tool 4 to deflect the tested tool 4 . The angle measuring device 6 is connected with the tool under test 4 for measuring the offset distance of the second end of the tool under test 4 .

[0061] Specifically, the main support 1 is vertical,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com