Pressure oil tank liquid and oil supplementing system and method

An oil system and oil tank technology, which is applied in the field of pressure oil tank filling and oil replenishment system, can solve the problems that the upper oil tank filling and oil replenishment scheme cannot be adopted, the equipment cost and operating cost increase, and the energy consumption increase, etc., to achieve reduction High requirements, reduce equipment operating costs, and reduce the effect of equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

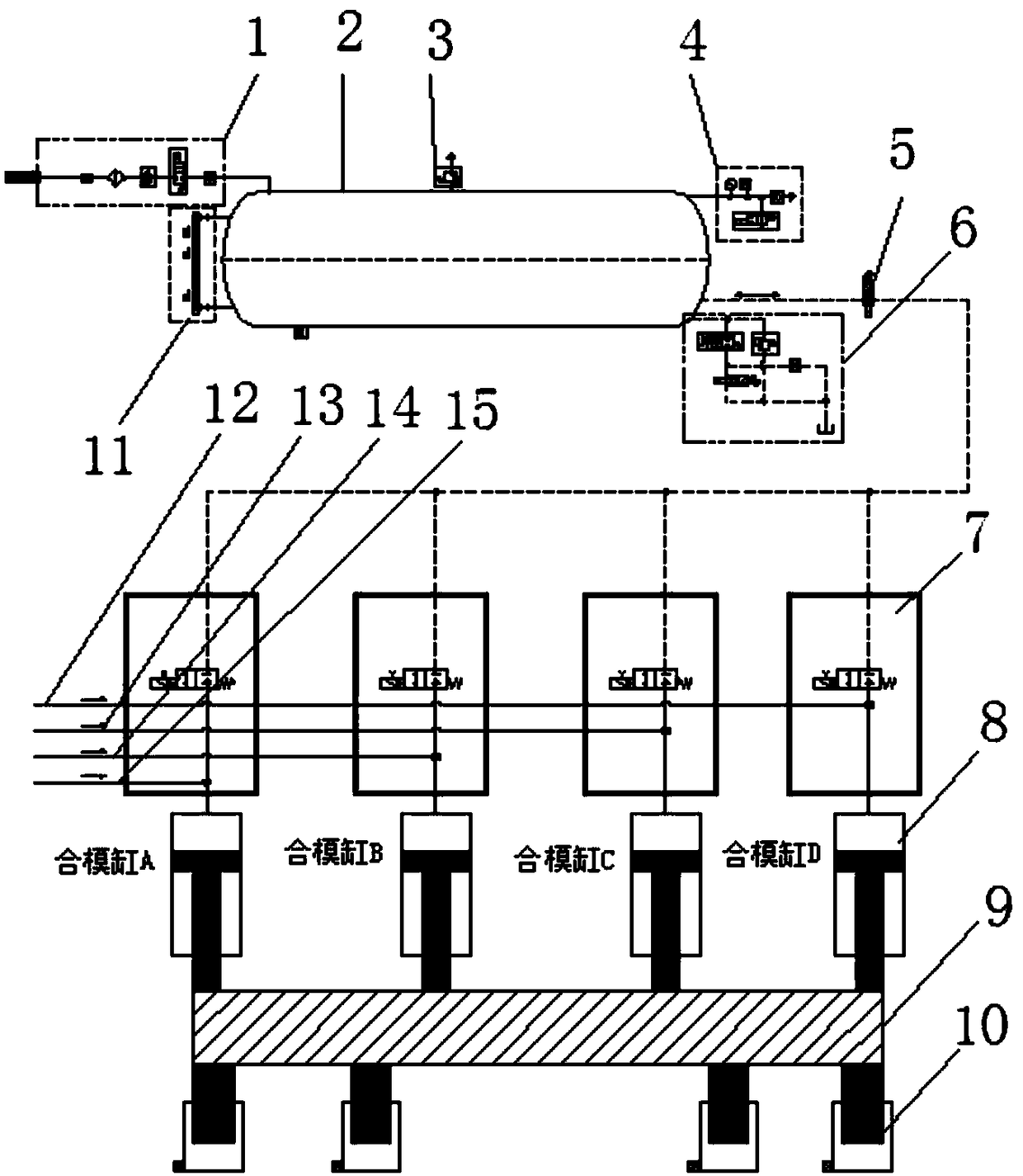

[0038] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0039] attached figure 1 It can be seen that a pressure oil tank filling and replenishing system includes an air charging device 1, a pressure oil tank 2, an air pressure safety valve 3, an air pressure measuring and deflation device 4, a liquid filling pipeline switch valve 5, and an oil safety oil discharge device 6 , liquid filling switch valve 7, clamping cylinder 8, press beam 9, press return cylinder 10, liquid level detection device 11, in the figure, 12 is pressure oil A, 13 is pressure oil B, 14 is pressure oil C, 15 is pressure oil D;

[0040] The inflation device 1 is connected with the pressure oil tank 2;

[0041] The inflation device 1 fills the pressure oil tank 2 with compressed air to ensure that the gas-liquid pressure in the pressure oil tank 2 reaches the set value; the pressure oil tank 2 is a pressure vessel for containing gas and liquid; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com