Spray building type gypsum double-layer thermal insulation composite outer wall and preparation method

A double-layer thermal insulation and spray construction technology, applied in thermal insulation, walls, buildings, etc., can solve the problems of easy fire, low strength of thermal insulation materials, inconvenient use, etc., and achieve the effect of avoiding thermal bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

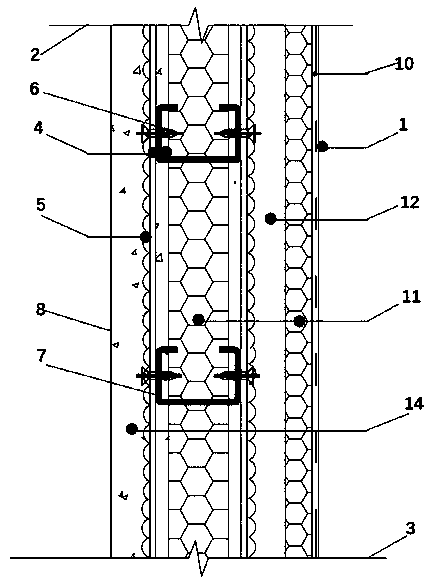

[0050] In conjunction with the accompanying drawings, the following examples describe a spray-built gypsum double-layer thermal insulation composite exterior wall. like figure 1 As shown, the exterior wall in this example is composed of waterproof and crack-resistant protective layer 1, wall upper end beam 2, wall lower end beam 3, light steel keel 4, steel wire mesh 5, screw 6, cage frame 7, wall The inner side 8 is formed, wherein the light steel keel 4 is arranged between the upper end beam 2 of the wall and the lower end beam 3 of the wall, and the screw 6 fixes the steel wire mesh 5 to the light steel keel 4; A cage frame 7 is composed of light steel keels 4, steel wire mesh 5, and screws 6, and is arranged between the upper end beam 2 of the wall and the lower end beam 3 of the wall, and between the cement mortar layer 12 and the gypsum mortar layer 14. Block the body of wall with cavity 13 in the wall.

[0051]In practice, in addition to installing the steel wire mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com