Thermal-bridge-free thermal insulation block containing T-shaped insulation boards

A technology of thermal insulation blocks and thermal insulation boards, which is applied in the direction of building materials, etc., can solve the problems that thermal bridges cannot be effectively solved, the effect of energy saving is not outstanding, and the effect of thermal insulation is not ideal, so as to improve the effect of energy saving and thermal insulation, improve the efficiency of masonry, The effect of resolving material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

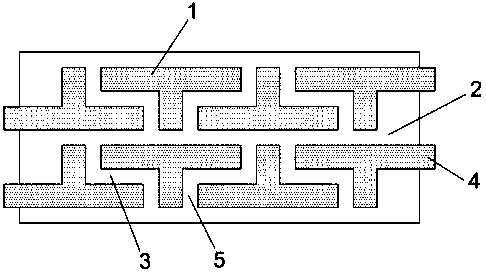

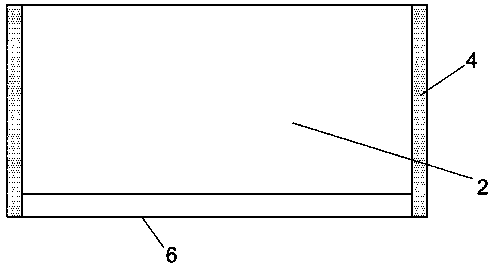

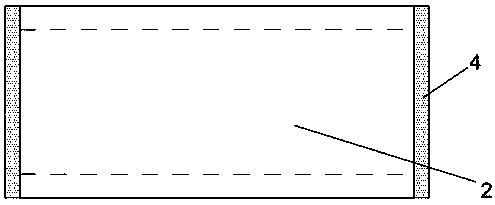

[0022] Example: such as Figure 1 to Figure 8 As shown, in the non-thermal bridge insulation block with T-shaped insulation boards, T-shaped insulation boards 1 are arranged side by side in concrete 2 in two rows, and T-shaped insulation boards 1 are made of rigid polyurethane material. Insulation boards 1 are staggered in front and back, and overlap each other. The overlapping length of adjacent T-shaped insulation boards 1 in the same row is 40mm in the longitudinal direction. Concrete longitudinal ribs 3 and concrete transverse ribs are formed between adjacent T-shaped insulation boards 1 in the same row. 5. The thicknesses of the concrete longitudinal ribs 3 and concrete transverse ribs 5 are all set at 25-30 mm. Different rows of concrete longitudinal ribs 3 and concrete transverse ribs 5 are arranged in alignment with the T-shaped insulation board 1. Two rows of T-shaped ribs near both ends of the block The thermal insulation board 1 protrudes from the left and right sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com