Composite carbon material lubricating additive, super-lubricity lubricant and preparation method and application thereof

A technology of lubricating additives and composite materials, applied in the field of super-slippery lubricants and nanomaterials, can solve the problems of inability to achieve super-slippery behavior, poor lubrication performance of pure water, easy rupture of water films, etc., and achieve good wear resistance and lubrication. Good performance and stable process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043]In the second aspect, the preparation method of the lubricating additive of the above-mentioned composite carbon material, the specific steps are:

[0044] 1) Mix dopamine hydrochloride solution, water, and Tris solution, then add HCl solution to adjust the pH value, then add nano-diamond colloid aqueous solution, and react to obtain polydopamine-wrapped nano-diamond composite material;

[0045] 2) adding the obtained polydopamine-wrapped nano-diamond composite material into the graphene oxide solution, and reacting to obtain the graphene oxide / polydopamine / nano-diamond composite material;

[0046] Or, 3) the graphene oxide / polydopamine / nanodiamond composite material obtained in step 2) is repeated successively in step 1) in the reaction mixed with dopamine hydrochloride, water, Tris solution, HCl solution and in step 2).

[0047] In some embodiments of the present invention, the reaction mixture obtained in step 3) is centrifuged, the supernatant is removed, and then fr...

Embodiment 1

[0071] 1) Prepare graphene oxide by Hummer method: first, cool the dry flask of 1000mL in ice-water bath for 5min, then add 100mL of analytically pure sulfuric acid, add 2g flake graphite, 1.8g copper nitrate, 5.4g sodium chlorate ( 2g flake graphite, 1.2g sodium nitrate, 8.0g potassium permanganate), control the reaction temperature at 5°C, and stir for 2h. Then, the flask was taken out, placed on a collector type constant temperature heating stirrer, and stirred and reacted at 35° C. for 2 h. Finally, 150 mL of deionized water was added, and then the reaction temperature was raised to 95° C. with a thermostat heating stirrer, and the stirring was continued for 1 h to obtain a graphite oxide solution. Prepare the required concentration by diluting as needed, and ultrasonically vibrate for 2 hours to obtain the graphene oxide solution with the required concentration.

[0072] 2) Prepare a 0.1 g / mL nano-diamond colloid aqueous solution in a 100 mL beaker, and then prepare 5.0 ...

Embodiment 2

[0075] The difference from Example 1 is that the concentration of the graphene oxide solution in step 3) is 1.0 mg / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

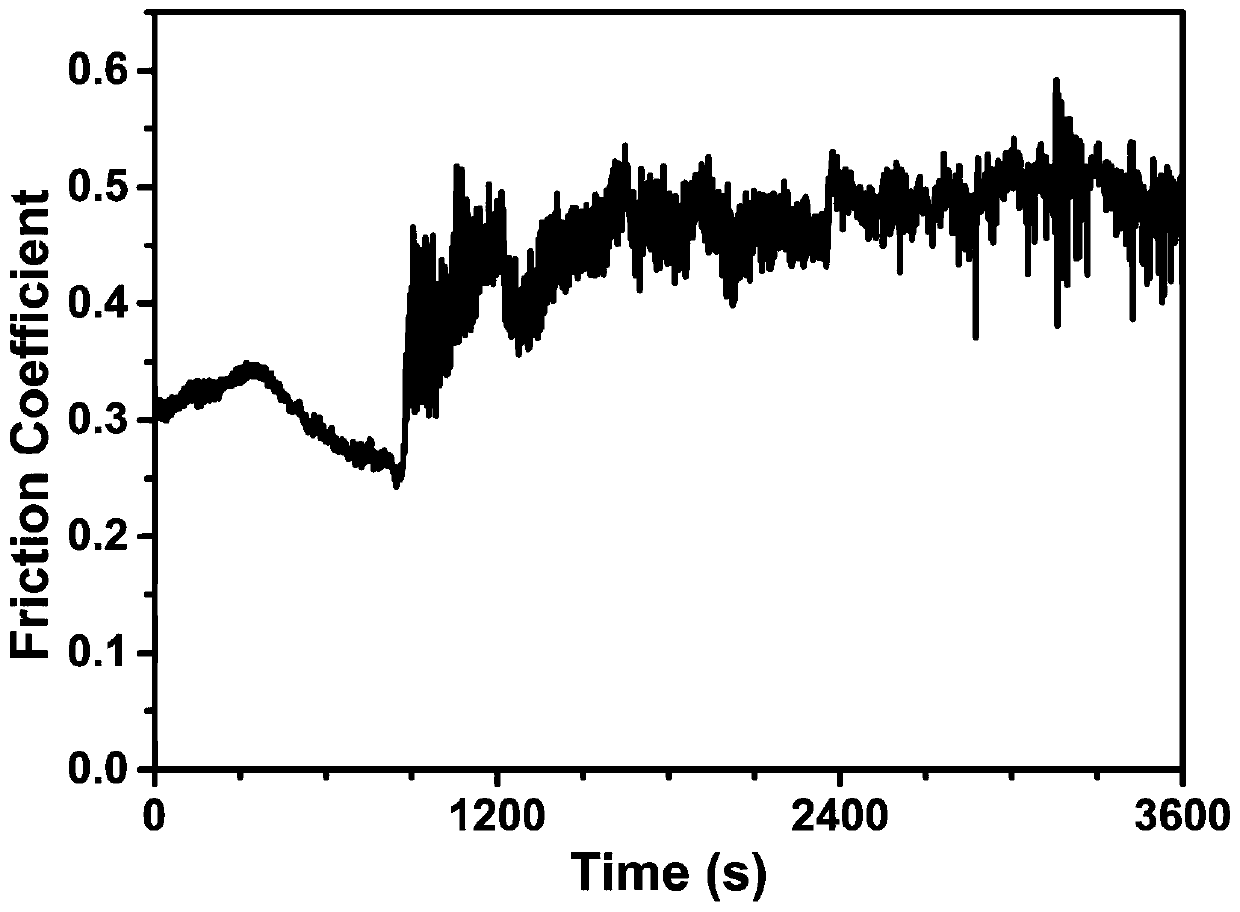

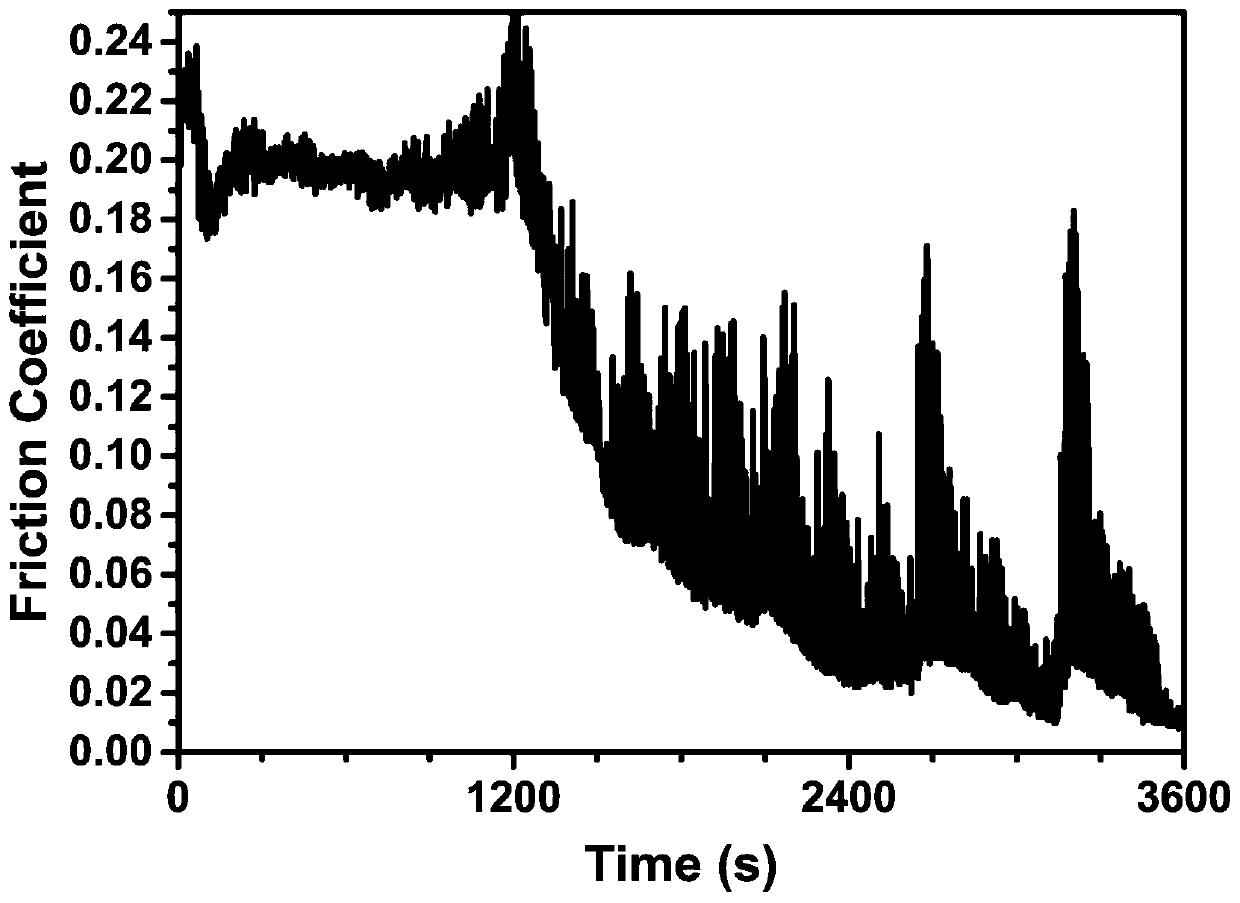

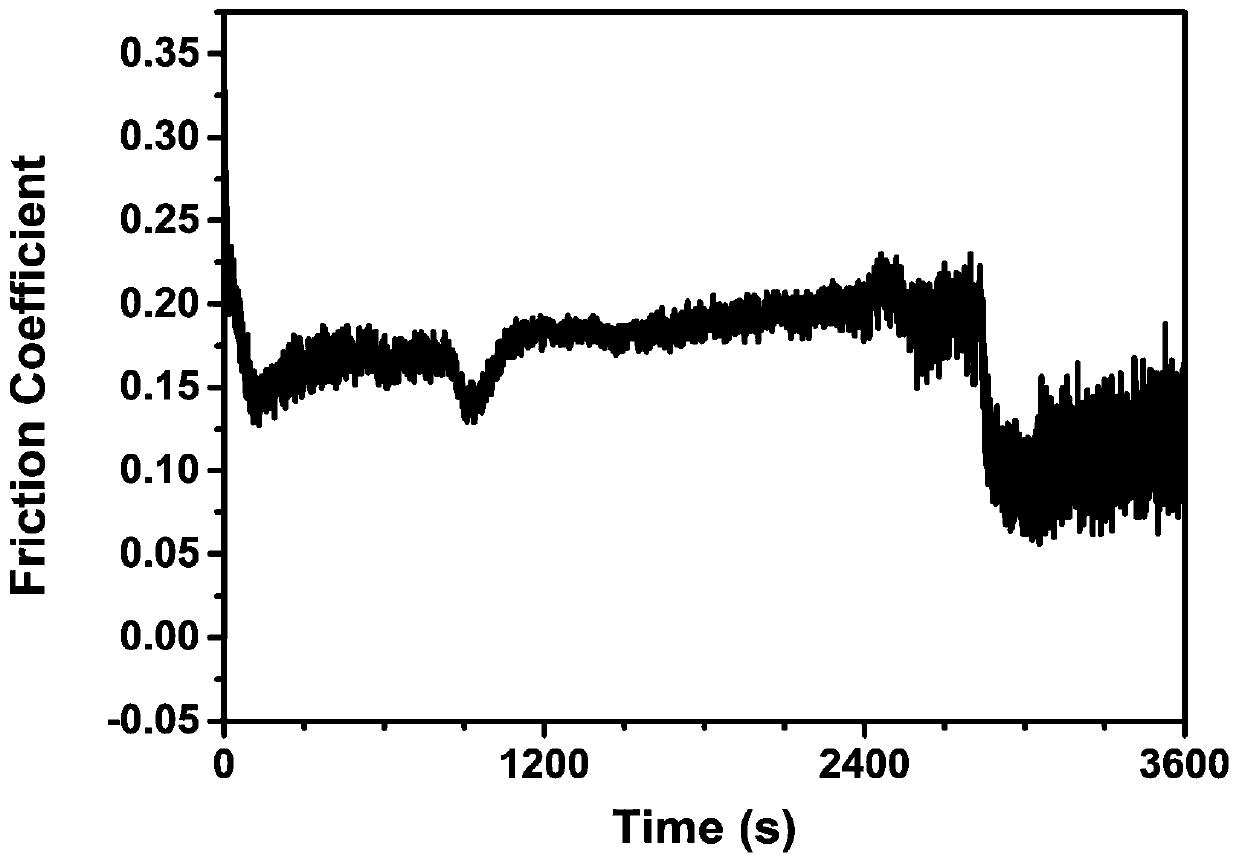

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com