Electromagnetic shielding material with a three-layer structure and preparation method thereof

A technology of electromagnetic shielding material and three-layer structure, which is applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of heavy electromagnetic shielding material, complicated processing process, low production efficiency, etc., and achieve low cost, Excellent thermal conductivity and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

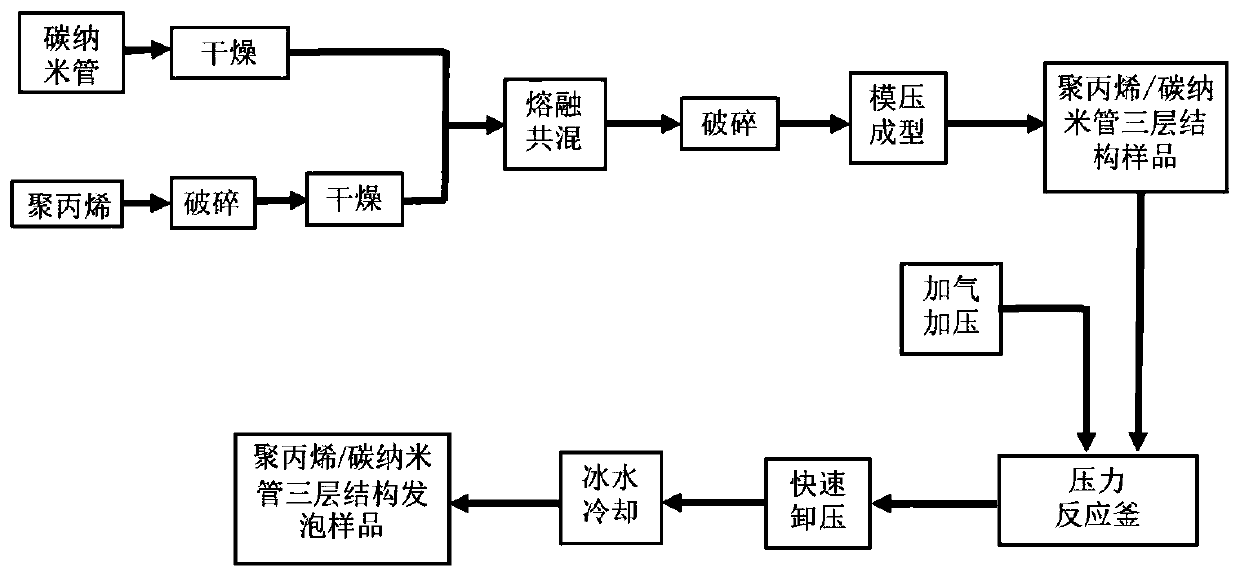

Method used

Image

Examples

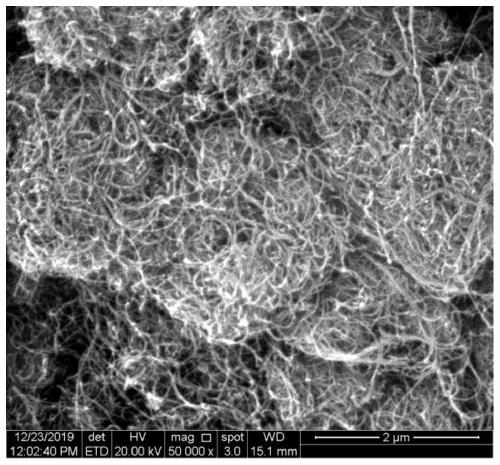

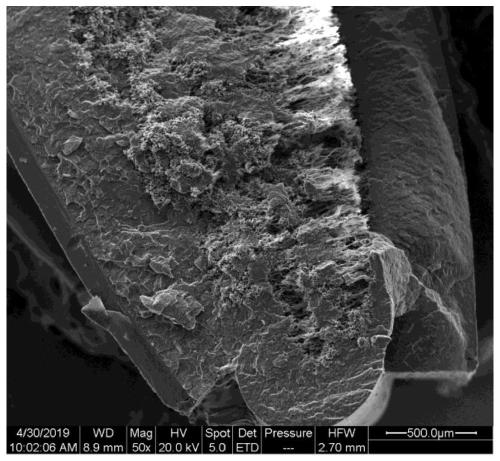

Embodiment 1

[0028] Prepare two groups of polypropylene by mass percentage: carbon nanotube=90:10, one group of polypropylene: carbon nanotube=97:3, wherein the diameter of polypropylene is 0.8mm, the obtained 3 groups of polypropylene / carbon nanotube The tubes were mechanically blended separately, and the resulting mixture was added to an internal mixer for heating, melting and blending to obtain a binary composite material. The binary composite material is granulated separately and then put into a mold and molded by a flat vulcanizing machine. Cut the polypropylene / carbon nanotube spline with a mass proportion of 3% carbon nanotubes into small squares with a thickness of 1mm, and obtain two groups of polypropylene / carbon nanotubes with a mass proportion of 10% carbon nanotubes The splines were cut into small squares with a thickness of 0.45 mm, and the mold was placed on a flat vulcanizing machine for thermocompression molding. The placement order from top to bottom is: the spline with ...

Embodiment 2

[0030] The difference from Example 1 is only that the foaming pressure of the autoclave is 11 MPa; the electromagnetic shielding efficiency of the obtained electromagnetic shielding material is 30.0 dB.

Embodiment 3

[0032] The difference from Example 1 is only that the foaming pressure of the autoclave is 14MPa; the electromagnetic shielding efficiency of the obtained electromagnetic shielding material is 25.9dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com