Environment-friendly hot melt adhesive attached three-in-one material for mask and preparation method thereof

An environmentally friendly, hot-melt adhesive technology, applied in separation methods, chemical instruments and methods, applications, etc., can solve the problems of short mask effective time, inability to block fine particles, mask effect failure, etc., and achieve long protection time , good physical properties, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

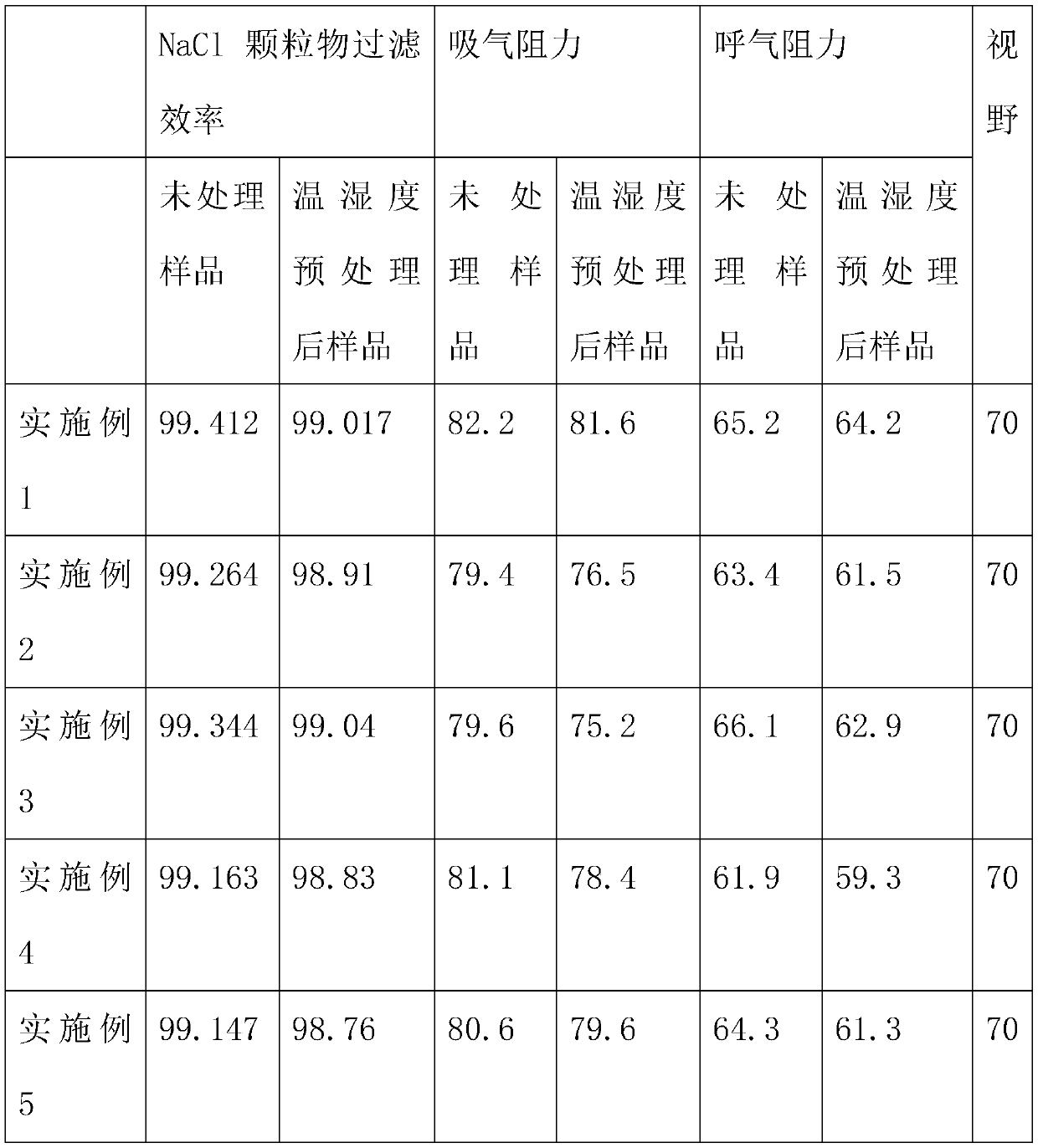

Embodiment 1

[0039] A three-in-one material for environmental protection hot melt adhesive bonding of masks, including an upper protective layer, a middle filter layer and a lower protective layer parallel to each other, between the upper protective layer and the middle filter layer and between the middle filter layer and the lower filter layer The protective layers are fixedly connected by hot-melt adhesive films.

[0040] The upper protective layer is made of PP non-woven fabric.

[0041] The middle filter layer is made of ePTFE nanofiber membrane made of expanded polytetrafluoroethylene.

[0042] The lower protective layer is made of PP non-woven fabric.

[0043] The hot-melt adhesive film is a polyurethane hot-melt adhesive film with a melting point of 120°C.

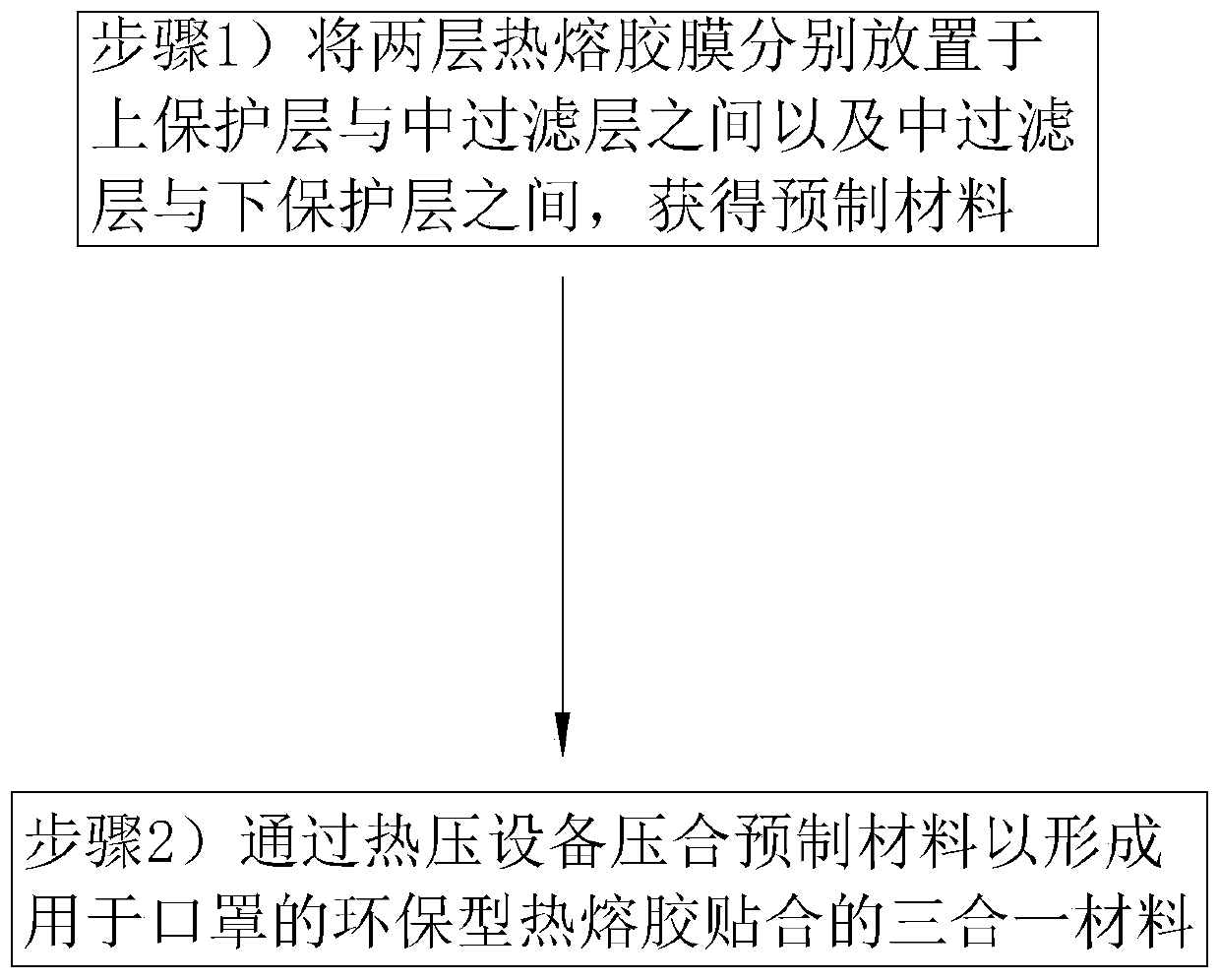

[0044] refer to figure 1 , the preparation method of the three-in-one material used for the environmentally friendly hot melt adhesive bonding of masks is as follows:

[0045]Step 1), place the upper protective layer, the mi...

Embodiment 2

[0048] A three-in-one material that is used for environmental protection type hot-melt adhesive bonding of masks, compared with Example 1, the difference is only:

[0049] The hot melt adhesive film is a polyurethane hot melt adhesive film with a melting point of 135°C.

[0050] In step 2), the pressing temperature is 190°C, the pressing time is 20s, and the pressing pressure is 2.5kgf / m 2 .

Embodiment 3

[0052] A three-in-one material that is used for environmental protection type hot-melt adhesive bonding of masks, compared with Example 1, the difference is only:

[0053] The hot melt adhesive film is a polyurethane hot melt adhesive film with a melting point of 150°C.

[0054] In step 2), the pressing temperature is 200°C, the pressing time is 10s, and the pressing pressure is 3kgf / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com