Multifunctional auxiliary shearing device for sheep breeding

A multi-functional and equipment technology, applied in the breeding industry, can solve the problems of difficult pruning, injury to workers, inconvenient operation of sheep, etc., and achieve the effect of speeding up pruning efficiency, avoiding injury, and convenient operation of shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

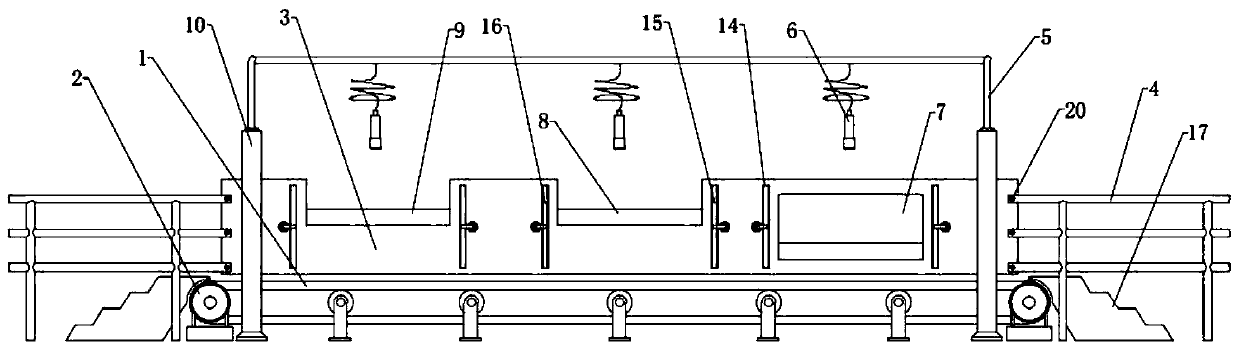

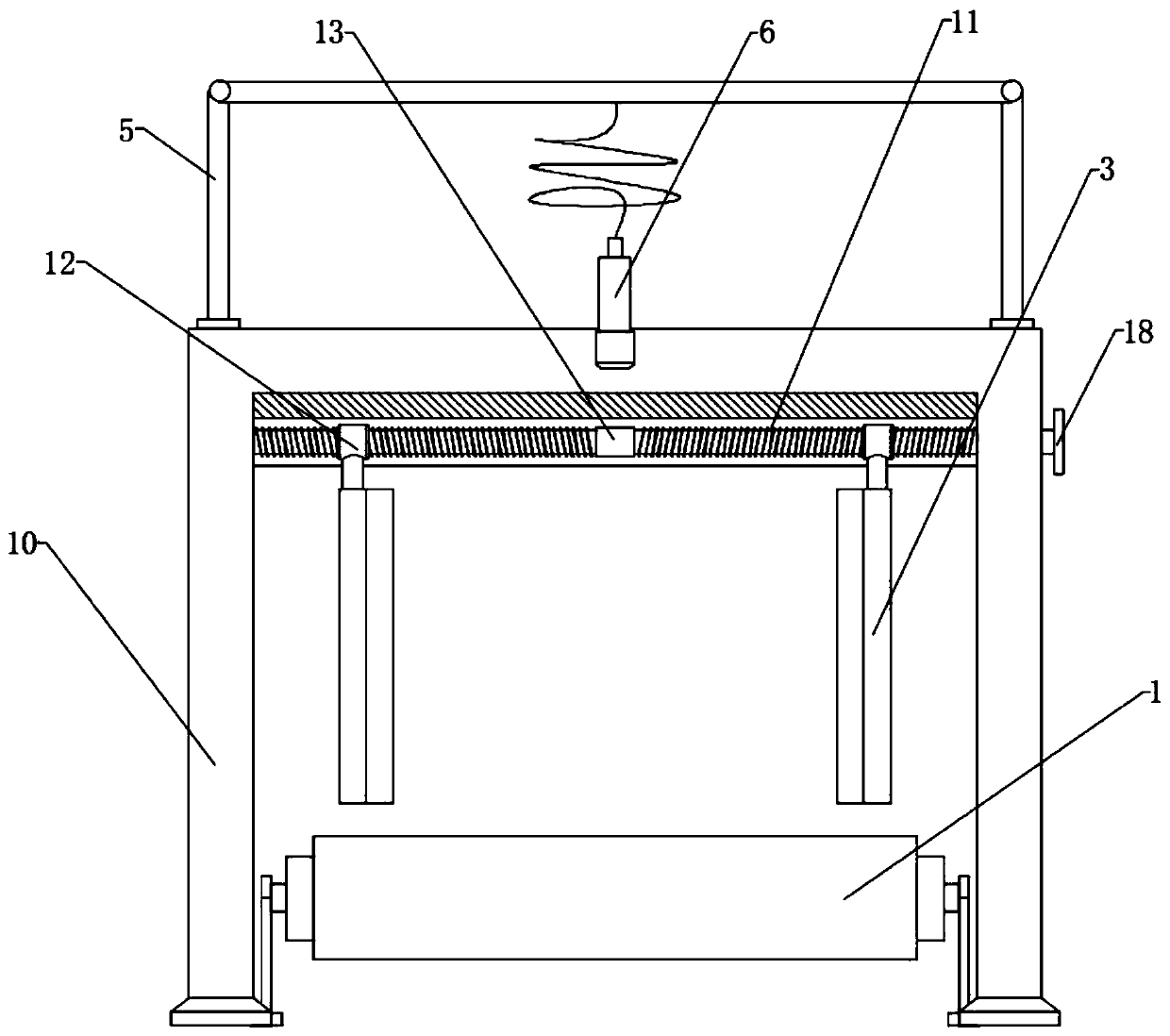

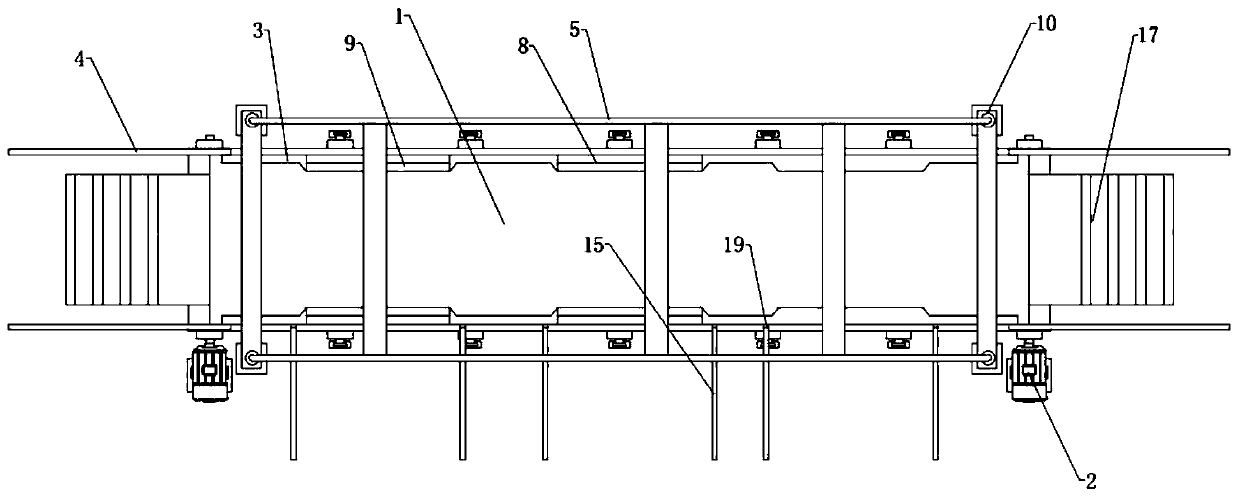

[0028]Example: according to the instructions attached figure 1 -5 It can be seen that this case is a multifunctional auxiliary shaving equipment for sheep breeding, which is mainly composed of a horizontally arranged conveying device and a bracket 5 installed outside the conveying device. The main body of the conveying device is a plate conveyor belt 1, and the plate conveying device Both ends of the belt 1 are respectively provided with a pair of traction motors 2 to be connected to the slat conveyor 1, and a pair of driving guardrails 4 are respectively provided on both sides of the slatted conveyor belt 1; connection; the conveying device is respectively provided with a number of different operating stations, and the bracket 5 and located in different stations are respectively provided with trimmers 6 matched with the number thereof, in the specific implementation process, the traction motor 2 is used as a traction force to drive the plate type The conveyor belt 1 operates,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com