Raschig ring one-step forming die

A technology of forming die and Raschig ring, applied in forming tools, manufacturing tools, feeding devices, etc., can solve the problems of reducing production efficiency, time-consuming, time-consuming and laborious, etc., and achieve the effect of improving production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

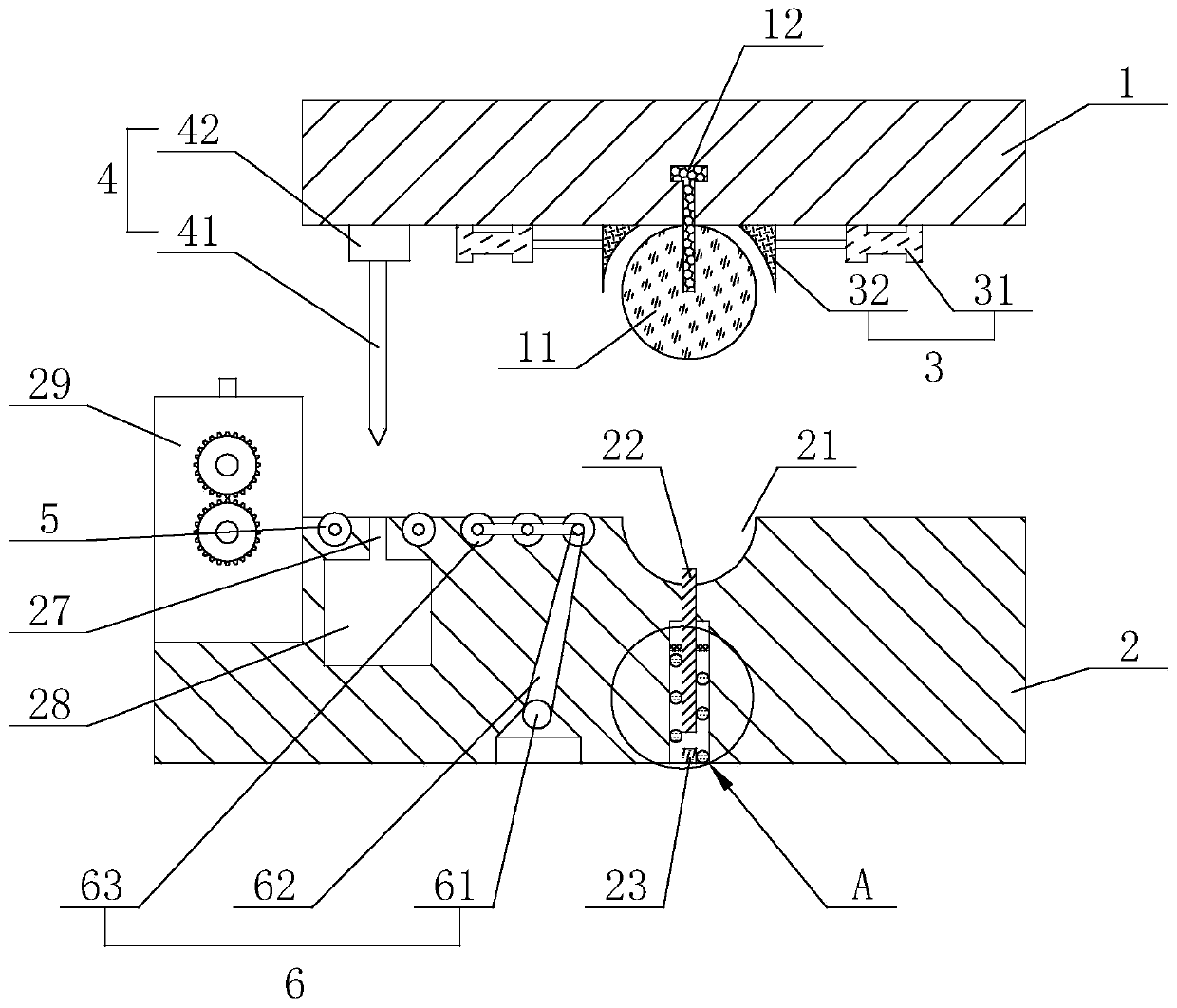

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

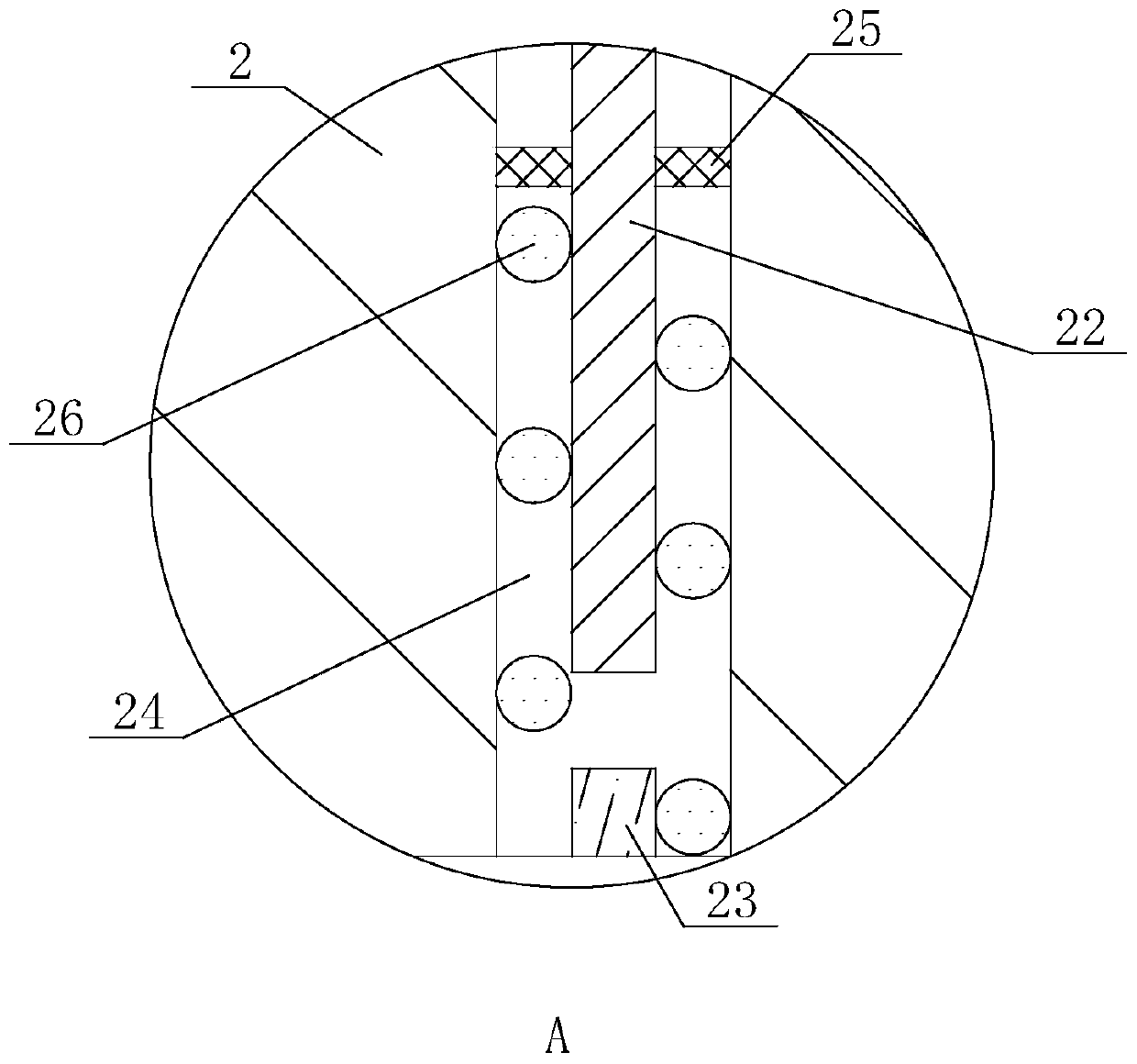

[0038] refer to figure 1 , is a Raschig ring one-time molding die 11 disclosed in the present invention, including an upper die 1 and a lower die 2, and the side of the upper die 1 close to the lower die 2 is detachably and fixedly connected with a forming die 11, and the left and right sides of the forming die 11 Extrusion mechanisms 3 for attaching the stainless steel plate to the molding die 11 are respectively provided on the sides. Wherein, the upper die 1 close to the lower die 2 is fixedly connected with a screw rod 12, and a threaded hole is provided in the molding die 11, and one end of the screw rod 12 is threadedly connected with the threaded hole. The forming die 11 is threadedly connected to one end of the screw rod 12, which not only increases the stability of the forming die 11 being fixed on the upper die 1, but also facilitates the removal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com