Immobilized metal organic catalyst for disproportionation reaction, and preparation method thereof

A metal-organic, disproportionation reaction technology, applied in the preparation of organic carbonates, organic compounds/hydrides/coordination complex catalysts, physical/chemical process catalysts, etc. Achieve the effect of improving acidity and activity, improving separation, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add HKUST-1 to Bu 2 In SnO solution (Bu 2 The mass ratio of SnO to HKUST-1 is 3:7), adding anhydrous toluene, heating to reflux at 110°C for 6h, filtering, washing, and vacuum drying overnight to obtain the solid-supported organometallic catalyst 1.

[0023] Methylphenyl carbonate is subjected to decompression disproportionation reaction under the above-mentioned catalyst 1. The reaction process conditions are: under nitrogen condition, 0.5mol methyl phenyl carbonate is added in a 150ml three-necked flask, and the catalyst is added. The amount of catalyst It is 2 wt% of the mass of methyl phenyl carbonate, and reacted for 5 hours at a pressure of 228mmHg and a reaction temperature of 170°C. Diphenyl carbonate was obtained, and the results are shown in Table 1.

Embodiment 2

[0025] Add graphene to Bu 2 In SnO solution (Bu 2 The mass ratio of SnO to graphene is 3:7), adding anhydrous toluene, heating to reflux at 110°C for 6h, filtering, washing, and vacuum drying overnight to obtain the solid-supported organometallic catalyst 2.

[0026] The disproportionation reaction method and conditions are the same as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0028] Add silicone to Bu 2 In SnO solution (Bu 2 The mass ratio of SnO to organic silica gel is 3:7), adding anhydrous toluene, heating to reflux at 110°C for 6h, filtering, washing, and vacuum drying overnight to obtain the solid-supported organometallic catalyst 3.

[0029] The disproportionation reaction method and conditions are the same as in Example 1, and the results are shown in Table 1.

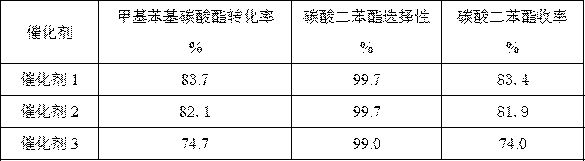

[0030] Table 1

[0031]

[0032] It can be seen from Table 1 that the same organometallic catalyst is immobilized on different supports, and the catalytic activity of the catalyst is different, mainly because the content of OH on different supports is different. The more content on the carrier, the higher the catalytic activity of the catalyst. From the data in the table, using HKUST-1 as the catalyst carrier has a good catalytic effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com