Full-mixed-flow high-shear mixer

A high-shear mixer and fully mixed flow technology, which is applied in the direction of mixers, mixers with rotating stirring devices, drive agitator dissolution, etc., can solve the problem of inability to exert high shear shearing, crushing, mixing capabilities, and lack of fluid The effects of shearing, mixing and dispersing with the bottom wall of the stator are not ideal, so as to meet the needs of green production, energy saving and emission reduction, and increased crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

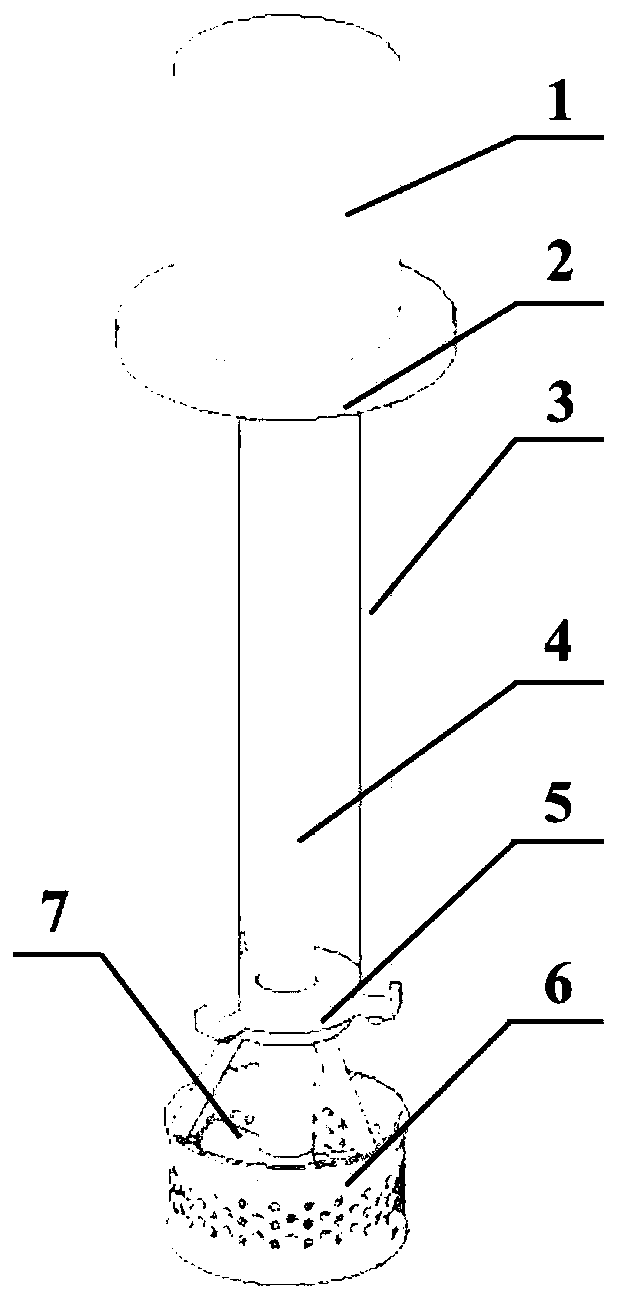

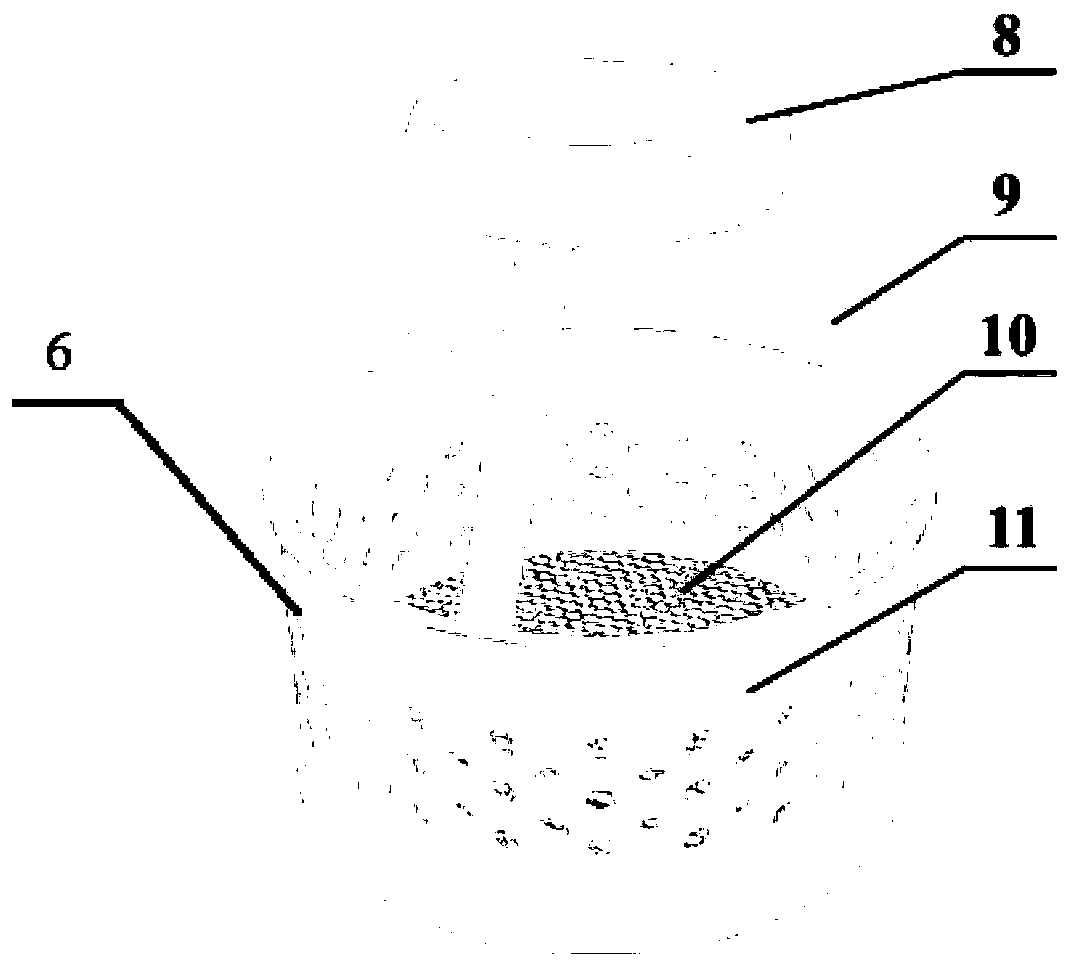

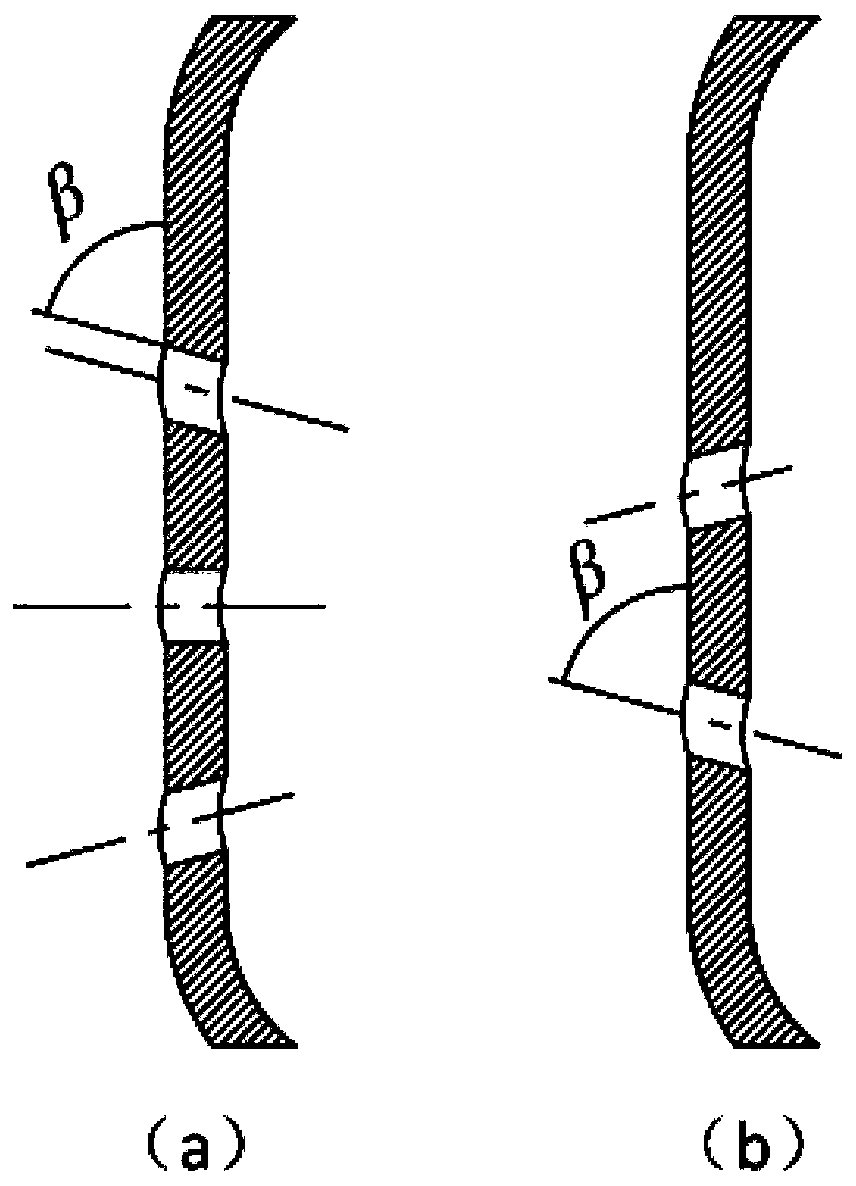

[0020] A full mixed flow high shear mixer (see figure 1 ), including a motor 1 and a main rotating shaft 4, the main rotating shaft 4 runs through the fixed disk 2 and the connecting disk 5, so that the fixed disk 2 is located at the upper end of the main rotating shaft 4, and the connecting disk 5 is located at the bottom of the main rotating shaft 4; The lower end of the rotating shaft 4 is connected with the rotor 7, and the fixed disc 2 is connected with the connecting disc 5 through the fixed rod 3; the connecting disc 5 and the flange 8 (see figure 2 ) connection, the flange 8 is connected with the stator 6 through the support rod 9, and the stator includes a cylindrical side wall 11 and a bottom wall 10 ( image 3 and Figure 4 ), the side wall is provided with a row of holes for regulating the jet flow direction, and the bottom wall is a 3-layer screen, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com