Polypyrrole/manganese dioxide-methylene blue nano composite particle and preparation method thereof

A technology of nano-composite particles and manganese dioxide, which is applied in the direction of wave energy or particle radiation treatment materials, drug combinations, and pharmaceutical formulations, to achieve the effects of improving therapeutic effects, shortening reaction time, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation and characterization of polypyrrole / manganese dioxide-methylene blue nanocomposite particles:

[0045] (1) Dissolve 1.5g of polyvinyl alcohol 13000-23000 in 18mL of secondary water and stir at 80°C for 40 minutes; after the solution cools down to room temperature, add 1.25g of FeCl 3 ·6H 2 O, and stirred for 1 hour; then 135 μL of pyrrole monomer was added and stirred at 4°C for 4 hours; after the reaction, centrifuged and washed 5 times with hot secondary water to obtain polypyrrole nanoparticles, which were freeze-dried for later use.

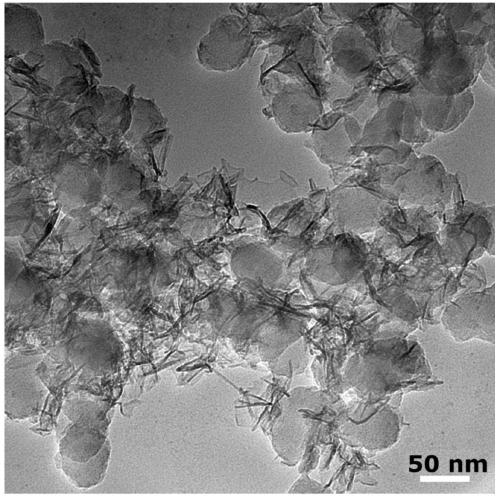

[0046] figure 1 In order to use a transmission electron microscope to characterize the morphology of the obtained polypyrrole nanoparticles, the scale bar is 200 nm. The results show that the obtained polypyrrole nanomaterials are spherical, with good dispersion and an average size of 68.18nm.

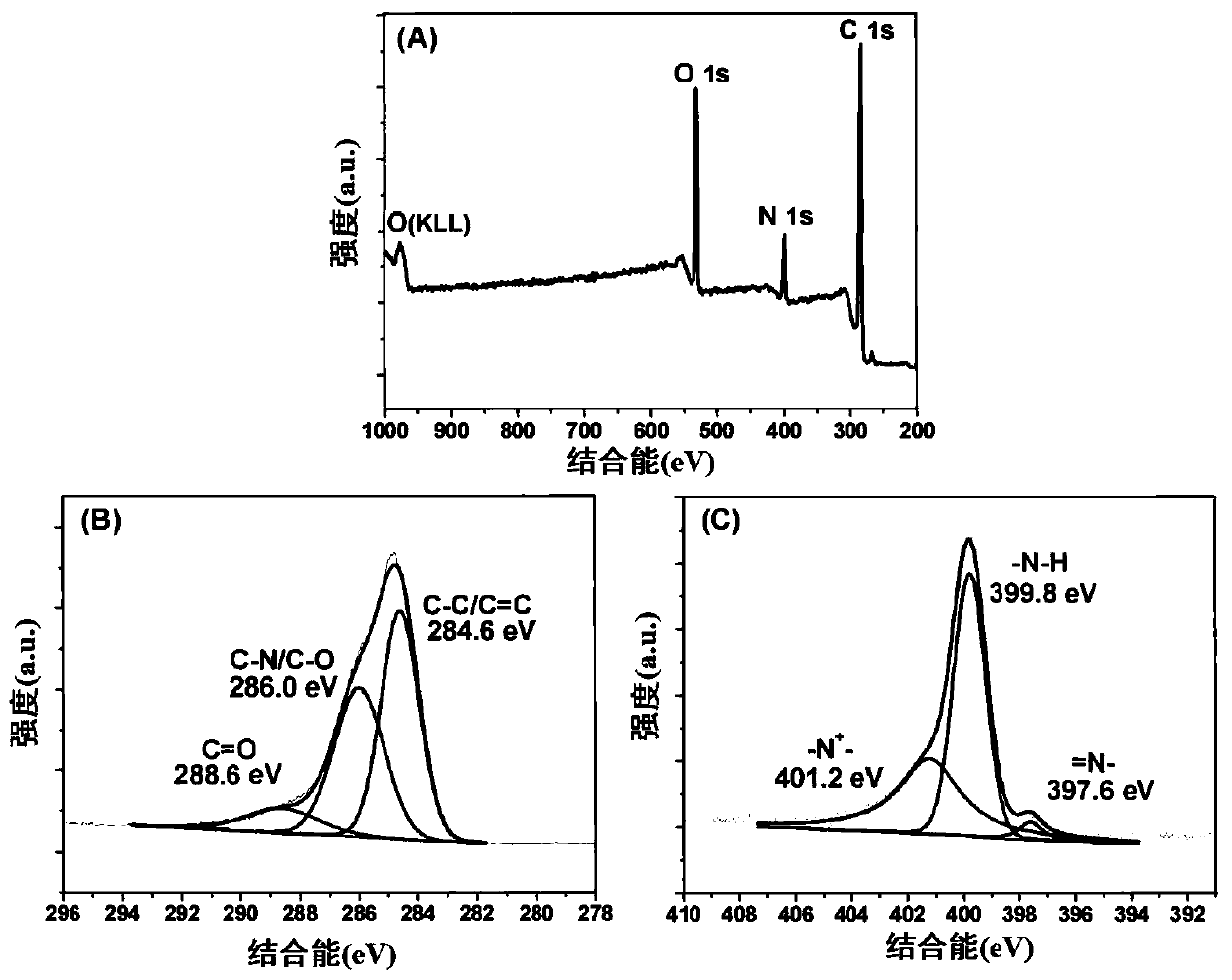

[0047] figure 2 For the result of characterizing the obtained polypyrrole nanoparticles by X-ray photoelectron spectrometer, ...

Embodiment 2

[0057] Preparation and characterization of polypyrrole / manganese dioxide-methylene blue nanocomposite particles:

[0058] (1) Dissolve 1.6g of polyvinyl alcohol 13000-23000 in 20mL of secondary water, stir at 75°C for 50 minutes; after the solution cools down to room temperature, add 1.3g of FeCl 3 ·6H 2 0, balanced stirring for 1.5 hours; then add 140 μL of pyrrole monomer, and stir for 4.5 hours at 3°C; after the reaction, centrifuge and wash with hot secondary water for 4 times to obtain polypyrrole nanoparticles, which are freeze-dried for later use;

[0059] (2) Disperse 20 mg of polypyrrole nanoparticles prepared in step (1) in 8 mL of secondary water by ultrasonic dispersion, and set aside; dissolve 12.5 mg of potassium permanganate in 12 mL of secondary water, and add it dropwise to the above dispersed Stirring in the polypyrrole nanoparticles, reacting for 15 minutes, washing with secondary water and absolute ethanol three times alternately, and drying to obtain poly...

Embodiment 3

[0063] Preparation and characterization of polypyrrole / manganese dioxide-methylene blue nanocomposite particles:

[0064] (1) Dissolve 1.55g of polyvinyl alcohol 13000-23000 in 19mL of secondary water and stir at 70°C for 45 minutes; after the solution has cooled to room temperature, add 1.2g of FeCl 3 ·6H 2 O, and stirred for 1 hour; then added 138 μL of pyrrole monomer, and stirred for 3.5 hours at 5° C.; after the reaction, centrifuged, and washed with hot secondary water for 3 times to obtain polypyrrole nanoparticles, freeze-dried for later use;

[0065] (2) Disperse 17 mg of polypyrrole nanoparticles prepared in step (1) in 8 mL of secondary water by ultrasonic dispersion and set aside; dissolve 5 mg of potassium permanganate in 12 mL of secondary water and add dropwise to the dispersed polypyrrole nanoparticles. Stirring in the pyrrole nanoparticles, reacting for 5 minutes, washing with secondary water and absolute ethanol four times alternately, and drying to obtain p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com