Antibacterial softening shampoo and production method thereof

A shampoo and softening technology, applied in hair care, pharmaceutical formulations, cosmetics, etc., can solve the problems of unsatisfactory antibacterial effect of shampoo, strong decontamination effect, dry hair, etc. Hair smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

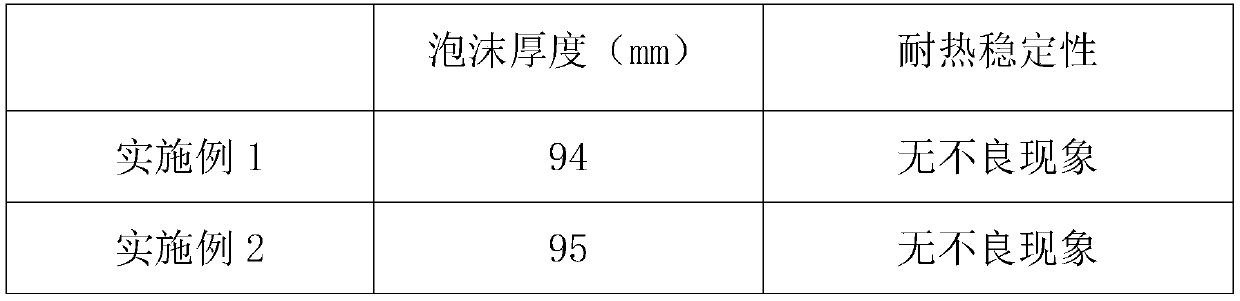

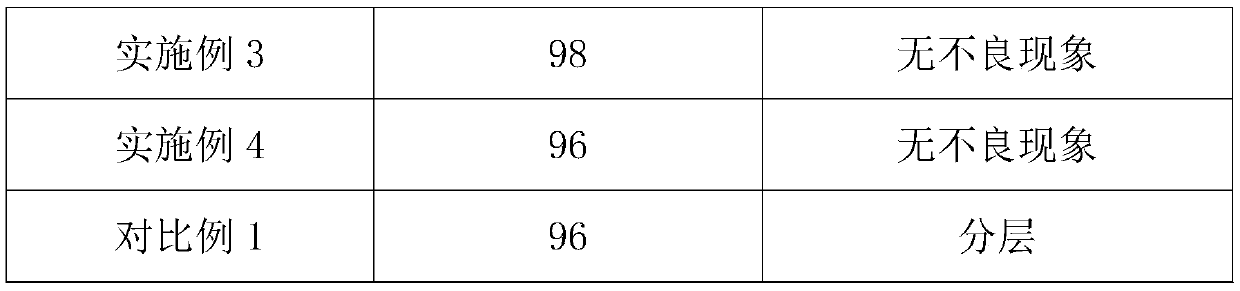

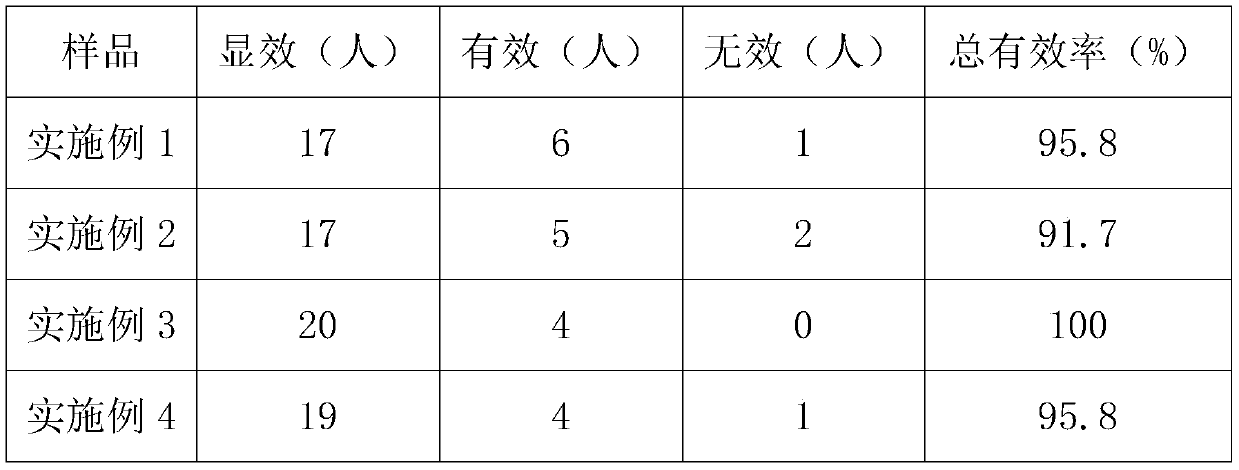

Examples

Embodiment 1

[0022] A kind of antibacterial soft shampoo proposed by the present invention comprises the following raw materials in parts by weight: 2 parts of monoglyceride succinate, 1 part of purslane extract, 6 parts of squalane, 2 parts of xylitol, dodecane 1.0 parts of sodium phenylsulfonate, 0.6 parts of sodium cocoyl glutamate, 0.38 parts of sodium hyaluronate, 0.4 parts of polyquaternium-10, 0.8 parts of xanthan gum, and 80 parts of deionized water; Amaranth extract is prepared by the following method: wash purslane with appropriate amount of deionized water for 3 times, dry, add a composite extractant that is 5 times the mass of purslane after drying, extract at 70°C for 2 hours, and use 200-mesh gauze Filtrate, take the filtrate, concentrate under reduced pressure, and vacuum-dry at 50°C for 4 hours to obtain a dried product. Add an appropriate amount of petroleum ether to the dried product, stir for 20 minutes, and place it in a refrigerator at 4°C for 4 hours. After taking it o...

Embodiment 2

[0029] A kind of antibacterial soft shampoo proposed by the present invention comprises the following raw materials in parts by weight: 4 parts of monoglyceride succinate, 1 part of purslane extract, 8 parts of squalane, 6 parts of xylitol, dodecane 0.8 part of sodium phenylsulfonate, 0.6 part of sodium cocoyl glutamate, 0.38 part of sodium hyaluronate, 0.1 part of polyquaternium-10, 0.8 part of xanthan gum, 80 parts of deionized water; Amaranth extract is prepared by the following method: wash purslane twice with an appropriate amount of deionized water, dry, add a composite extractant that is 8 times the mass of purslane after drying, extract at 70°C for 1 hour, and use 200-mesh gauze Filtrate, take the filtrate, concentrate under reduced pressure, and vacuum-dry at 50°C for 4 hours to obtain a dried product. Add an appropriate amount of petroleum ether to the dried product, stir for 20 minutes, and place it in a refrigerator at 4°C for 4 hours. After taking it out from the r...

Embodiment 3

[0036] A kind of antibacterial soft shampoo proposed by the present invention comprises the following raw materials in parts by weight: 4 parts of monoglyceride succinate, 0.8 parts of purslane extract, 8 parts of squalane, 4 parts of xylitol, dodecane 0.8 part of sodium phenylsulfonate, 1 part of sodium cocoyl glutamate, 0.32 part of sodium hyaluronate, 0.3 part of polyquaternium-10, 0.5 part of xanthan gum, 85 parts of deionized water; Amaranth extract is prepared by the following method: wash purslane with appropriate amount of deionized water for 3 times, dry, add a composite extractant that is 6 times the mass of purslane after drying, extract at 70°C for 1.5h, 200 mesh Filtrate through gauze, take the filtrate, concentrate under reduced pressure, and dry in vacuum at 50°C for 4 hours to obtain a dried product. Add an appropriate amount of petroleum ether to the dried product, stir for 25 minutes, and place it in a refrigerator at 4°C for 4 hours. After taking it out of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com