Sound producing device and method of manufacturing sound producing device

A technology for generating device and sound, which can be applied in the direction of sound-producing equipment, fluid using vibration, transducer of piezoelectric-electric polymer, etc., which can solve the problem of high material cost, brittle conductive adhesive, increased manufacturing cost and labor hours. and other problems, to achieve the effect of high strength, sufficient conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

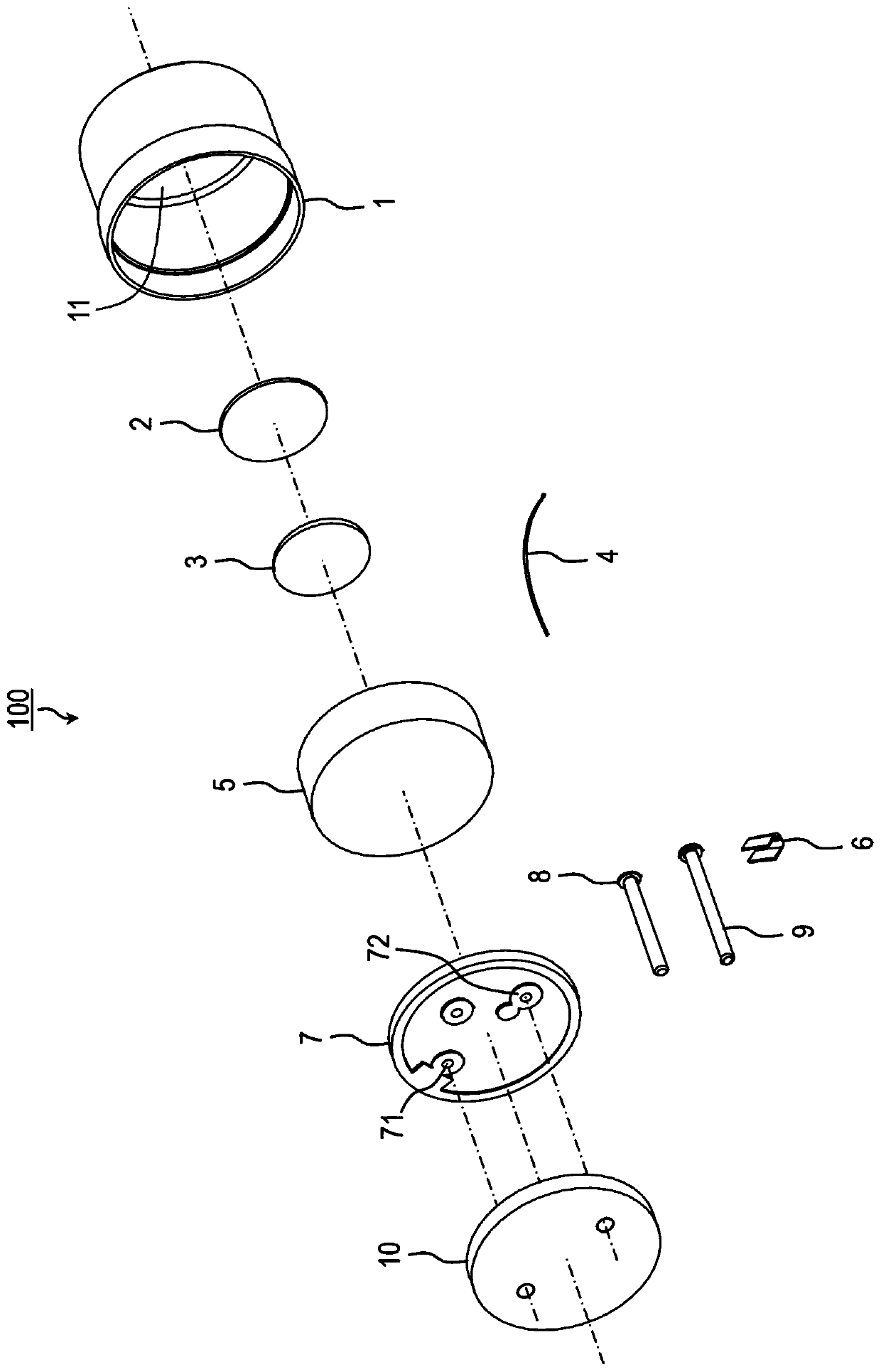

[0013] Below, refer to figure 1 The sound generator 100 of the first embodiment will be described. As shown in this figure, the sound generating device 100 is constituted to include: a cylindrical metal case 1 comprising a bottom surface and a cylindrical surface with an opening on the top; a thin disc-shaped adhesive layer 2; a thin disc-shaped The piezoelectric ceramic (piezoelectric element) 3 is bonded to the bottom surface (inner surface) of the metal case 1 through the adhesive layer 2; the cable 4 connects the piezoelectric ceramic (piezoelectric element) 3 and the substrate 7 Electrical connection; disk-shaped sponge 5, which is sandwiched between piezoelectric ceramics (piezoelectric element) 3 and substrate 7; copper foil 6, which fixes cable 4 to substrate 7; disk-shaped substrate 7; welding Negative-side pins 8 and positive-side pins 9 on the upper surface of the substrate 7 ; and a disk-shaped sealant 10 .

[0014]

[0015] In the cylindrical metal case 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com