Low-platinum proton exchange membrane fuel cell membrane electrode and preparation method thereof

A proton exchange membrane, fuel cell membrane technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of difficult to improve the performance of platinum carbon catalysts and platinum alloy catalysts, and the date of mass production is still in the future. Conducive to separation and recycling, improving recycling rate, and improving the effect of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a low-platinum proton exchange membrane fuel cell membrane electrode, comprising the following steps:

[0029] (1) Weigh 1 gram of 60% Pt / C catalyst (Jonson, UK) into a 50mL beaker, add 12.5mL deionized water, stir and disperse; measure 5mL isopropanol, 11mL Nafion with a mass fraction of 5% Mix the solution with 55mg of polyvinyl alcohol evenly, fully ultrasonically disperse to form catalyst ink, ultrasonically for 10min, and stand at 25°C for 5min;

[0030] (2) Set the area to 5*5cm 2 Soak the polytetrafluoroethylene porous material in the isopropanol solution for 10 minutes, take it out and dry it in an oven at 40°C;

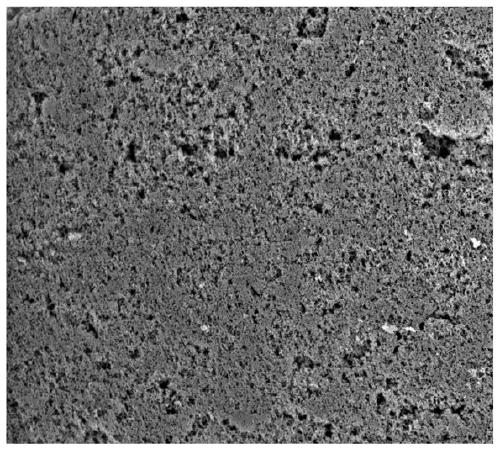

[0031] (3) Soak the porous material obtained in step (2) in the catalyst ink obtained in step (1) for 10 minutes and then dry it in an oven at 140°C for 3 minutes to obtain a porous catalytic layer;

[0032] (4) Spray 3 mL of Nafion solution with a mass fraction of 0.05% on the surface of the porous catalytic layer prepared in ...

Embodiment 2

[0036] A method for preparing a low-platinum proton exchange membrane fuel cell membrane electrode, comprising the following steps:

[0037] (1) Weigh 1 gram of 60% Pt / C catalyst (Johnson Matthey, UK) into a 50mL beaker, add 12.5mL of deionized water, stir and disperse; measure 5mL of isopropanol, 11mL of 5% mass fraction Mix Nafion solution and 30mg polyvinyl alcohol evenly, fully ultrasonically disperse to form catalyst ink, ultrasonically for 10min, and stand at 25°C for 5min;

[0038] (2) Set the area to 5*5cm 2 Soak the polytetrafluoroethylene porous material in the isopropanol solution for 10 minutes, take it out and dry it in an oven at 40°C;

[0039] (3) Soak the porous material obtained in step (2) in the catalyst ink obtained in step (1) for 20 minutes and then dry it in an oven at 140°C for 3 minutes to obtain a porous catalytic layer;

[0040] (4) Spray 3 mL of Nafion solution with a mass fraction of 0.05% on the surface of the porous catalytic layer prepared in ...

Embodiment 3

[0044] A method for preparing a low-platinum proton exchange membrane fuel cell membrane electrode, comprising the following steps:

[0045](1) Weigh 1 gram of 40% Pt / C catalyst (Johnson Matthey, UK) into a 50mL beaker, add 12.5mL of deionized water, stir and disperse; measure 5mL of isopropanol, 7mL with a mass fraction of 5% Mix Nafion solution and 30mg polyvinyl alcohol evenly, fully ultrasonically disperse to form catalyst ink, ultrasonically for 10min, and stand at 25°C for 5min;

[0046] (2) Set the area to 5*5cm 2 Soak the polytetrafluoroethylene porous material in the isopropanol solution for 10 minutes, take it out and dry it in an oven at 40°C;

[0047] (3) Soak the porous material obtained in step (2) in the catalyst ink in step (1) for 20 minutes, then dry it in an oven at 140°C for 3 minutes, and repeat this process 3 times to obtain a porous catalytic layer;

[0048] (4) Spray 3 mL of Nafion solution with a mass fraction of 0.05% on the surface of the porous ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com