Self-inspection circuit and self-inspection method of signal acquisition loop of vacuum degree monitoring device

A monitoring device and signal acquisition technology, applied in circuits, high-voltage air circuit breakers, electric switches, etc., can solve the problem that the effectiveness of the vacuum degree online monitoring system cannot be guaranteed, the vacuum degree of the vacuum circuit breaker cannot be effectively reflected, and the vacuum degree monitoring system is not effective. With self-check function and other issues, to achieve the effect of easy promotion, high reliability, and verification effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

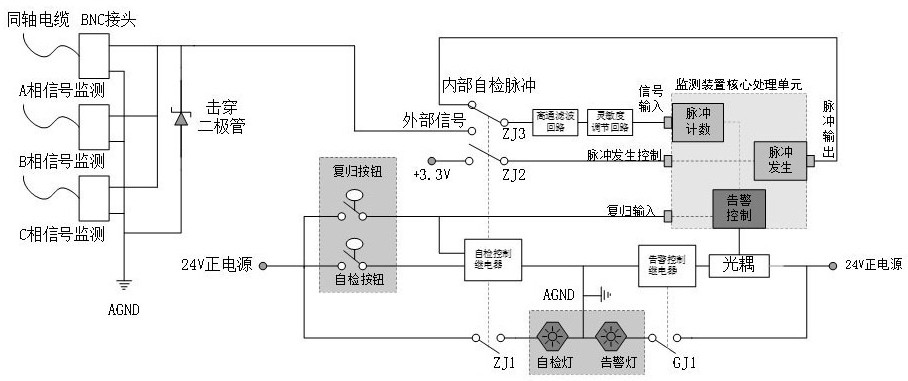

[0031] Such as figure 1 As shown, a signal acquisition loop self-test circuit of a vacuum degree monitoring device includes a vacuum degree monitoring device and a self-inspection unit connected to the core processing unit circuit of the vacuum degree monitoring device; the core processing unit of the vacuum degree monitoring device includes a pulse generator module, a pulse counting module and an alarm control module, the self-check unit includes a self-check button, a reset button, a self-check control relay, an alarm control relay, an optocoupler, a high-pass filter circuit and a sensitivity adjustment circuit, the self-check button and the The reset buttons are all connected to the self-inspection control relay, the self-inspection control relay, the alarm control relay, the optocoupler and the alarm control module are connected in sequence, and the self-inspection control relay controls the pulse generation module to send a pulse signal , the pulse signal enters the pulse...

Embodiment 2

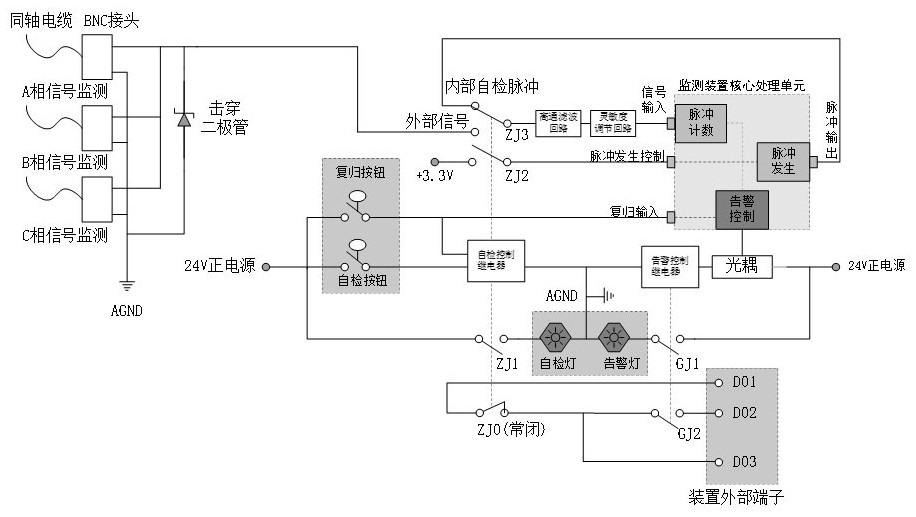

[0039] Such as Figure 2~3 , the vacuum degree monitoring device signal acquisition loop self-inspection circuit of the embodiment of the present invention is different from the first embodiment in that: the vacuum degree monitoring device external terminal D01, the self-inspection control relay self-inspection locking normally closed node ZJ0, the alarm control relay The node GJ2 is sequentially connected to the external terminal D02 of the vacuum degree monitoring device, and the external terminal D03 of the vacuum degree monitoring device is connected to the self-inspection locking normally closed node ZJ0 of the self-inspection control relay.

[0040] The panel of the vacuum monitoring device is provided with the self-test button, reset button, running light, self-test light and warning light.

[0041] In order to avoid the alarm signal generated by the self-inspection of the device in the operation and maintenance process from being falsely reported to the superior monito...

Embodiment 3

[0043] A method for self-inspection of a vacuum degree monitoring device signal acquisition loop, comprising the following steps: S1: Press the self-inspection button, the pulse generation input control node ZJ2 of the self-inspection control relay is closed, and the core processing unit of the vacuum degree monitoring device is controlled to output a self-inspection high At the same time, the self-inspection control relay signal selection switch node ZJ3 switches the external signal to the internal self-inspection pulse signal sent by the pulse generation module, and the self-inspection control relay node ZJ1 controls the self-inspection light to light up;

[0044] Press the self-test button, and at the same time block the normally closed node ZJ0 through the self-test control relay self-test, and block the external terminals D01 and D02 of the vacuum degree monitoring device to avoid sending the self-test alarm signal to the background processing system during operation and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com