Device for testing impact resistance of refractory castable for boiler cold ash bucket

A technology of refractory castables and impact resistance, which is applied in the directions of measuring devices, analysis materials, strength characteristics, etc., can solve the problems of deformation and cracking of cold ash hopper castables, and achieve the effect of ensuring the accuracy of the test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

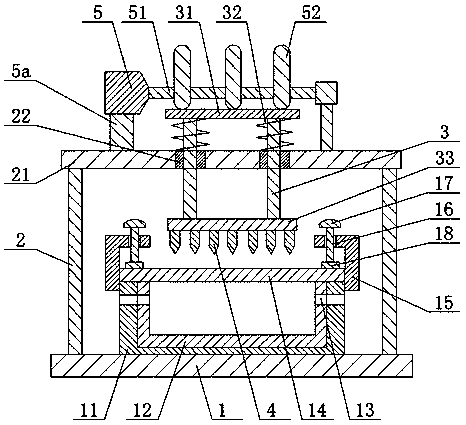

[0017] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and implementation methods.

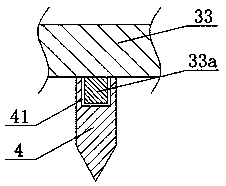

[0018] Such as figure 1 As shown, a test device for the impact resistance of refractory castables for boiler cold ash hoppers, including a base 1, the top of the base 1 is provided with a storage seat 11, the storage base 11 is fixedly connected with the base 1, and the inner wall of the storage base 11 is provided with concrete Layer 12, the storage seat 11 and the concrete layer 12 are all provided with air holes 13, and the top of the storage seat 11 is provided with a sample plate 14, and charcoal fire and other combustibles can be placed in the concrete layer 12, and the charcoal fire is used to heat the sample plate 14. 13 is convenient to feed oxygen and is beneficial to combustion; the storage seat 11 is U-shaped, and its end is symmetrically provided with a right-angle plate 15, which is fixedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com