Device for testing thermal response speed of shape memory material

A memory material and thermal response technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, analyzing materials, etc., can solve the problems that the thermal response speed cannot be directly fed back, and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

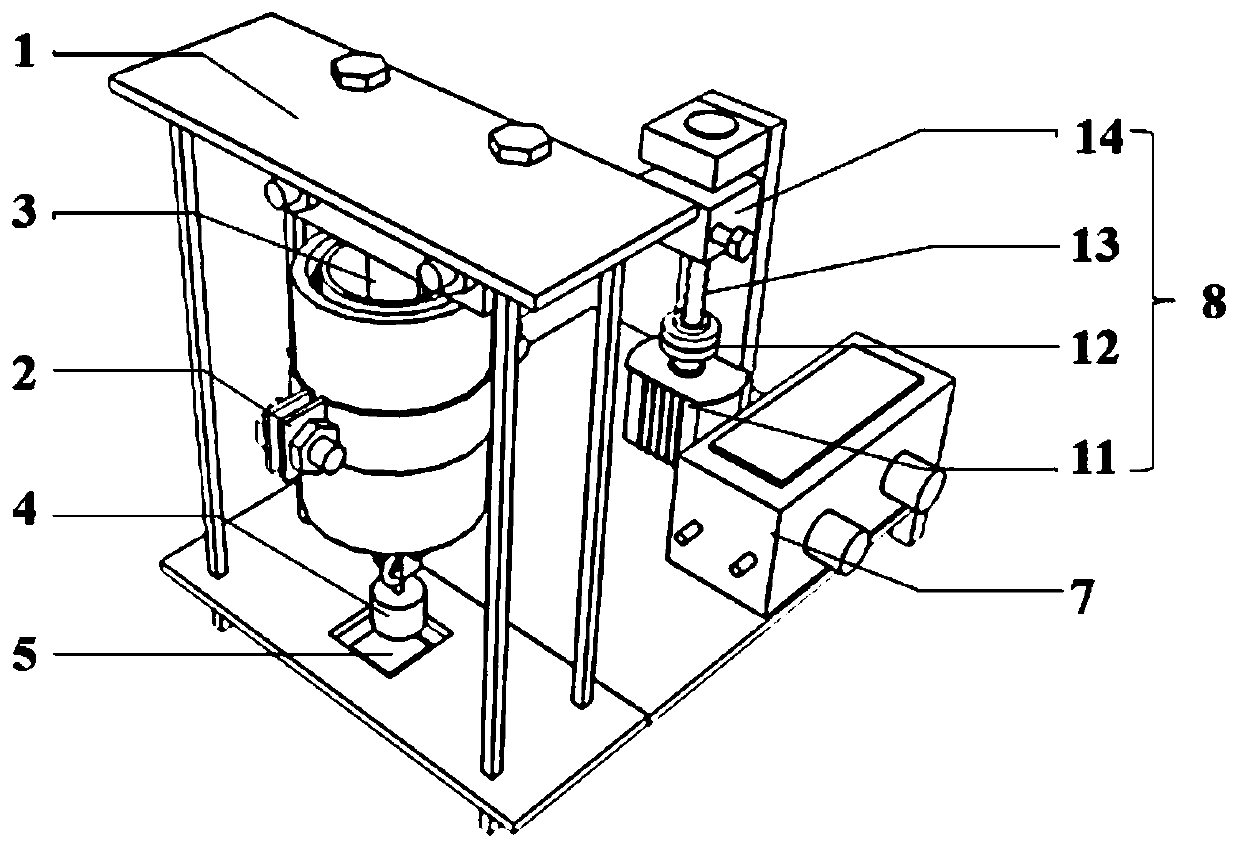

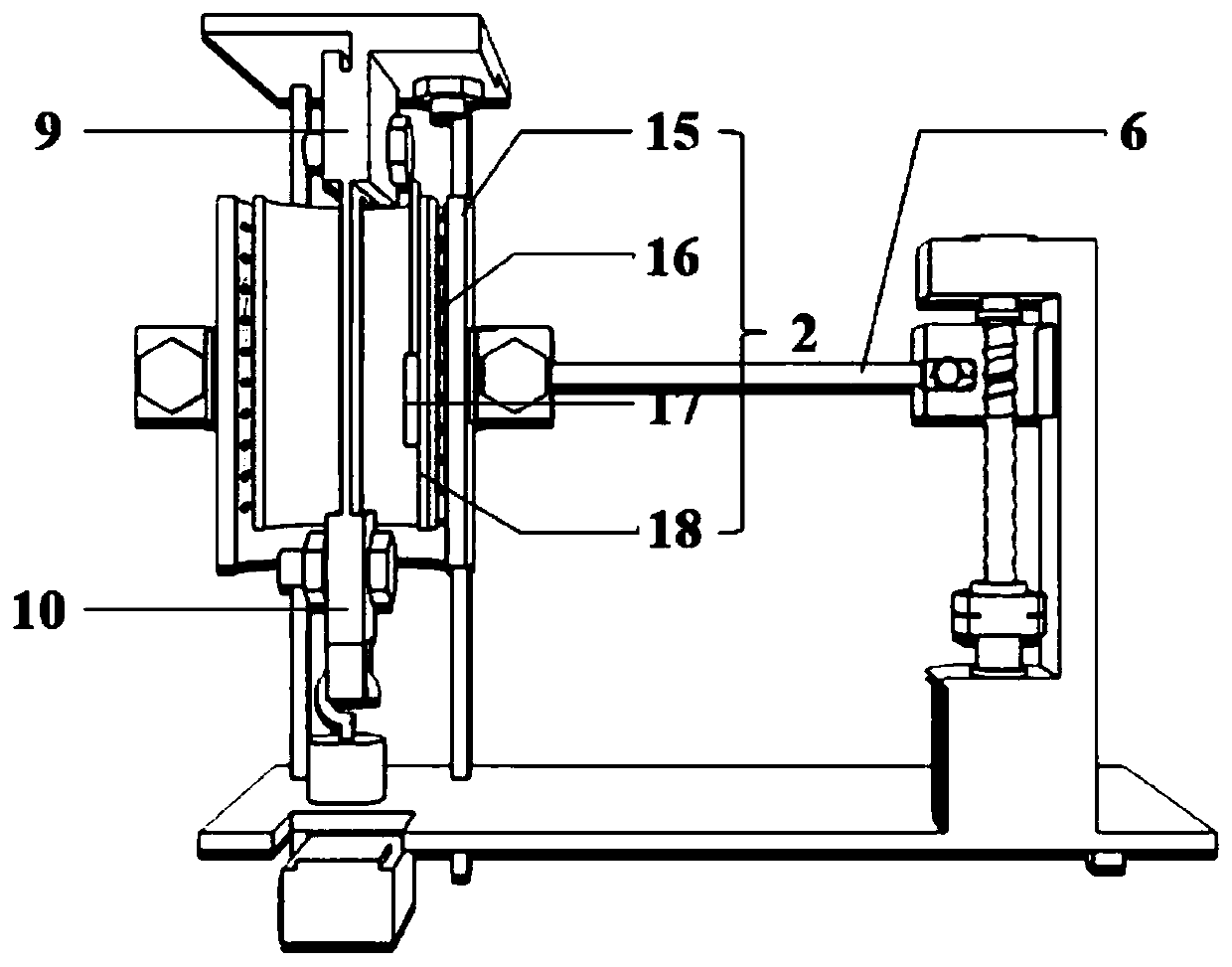

[0030] Such as figure 1 with 2 As shown, the device for testing the thermal response speed of shape memory materials in this embodiment includes a frame 1, a heating cylinder 2, a load weight 4, a displacement sensor 5, an adjustable voltage stabilized power supply 7, a lifting mechanism 8, an upper clamp 9 and Lower fixture 10.

[0031] The frame 1 is a vertical frame structure, including a bottom plate, a top plate and a column between the bottom plate and the top plate. The upper fixture 9 is fixedly installed on the top plate of the frame 1, the upper fixture 9 is used to clamp and fix the top of the test sample 3, the bottom of the test sample 3 is clamped and fixed with the lower fixture 10, and the load weight 4 is hoisted on the lower fixture 10 , so that the test sample 3, the lower clamp 10 and the load weight 4 are in a suspended state under the action of gravity. Wherein, the lower clamp 10 is preferably a U-shaped clamp, which facilitates switching of load weig...

Embodiment 2

[0041] The difference between the device for testing the thermal response speed of the shape memory material in this embodiment and the first embodiment is that:

[0042] The heating cylinder of this embodiment is directly fixed and installed in the middle of the frame, the setting of the lifting mechanism can be omitted, and the test of the thermal response speed of the shape memory material can also be realized, which simplifies the structure of the device and lowers the cost.

[0043] Other structures can refer to Embodiment 1.

Embodiment 3

[0045] The difference between the device for testing the thermal response speed of the shape memory material in this embodiment and the first embodiment is that:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com