Liquid storage tank and liquid feeding device

A technology for liquid storage tanks and tank covers, which is applied to liquid distribution, transportation or transfer devices, special distribution devices, packaging, etc., which can solve problems such as troubles and achieve the effect of easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

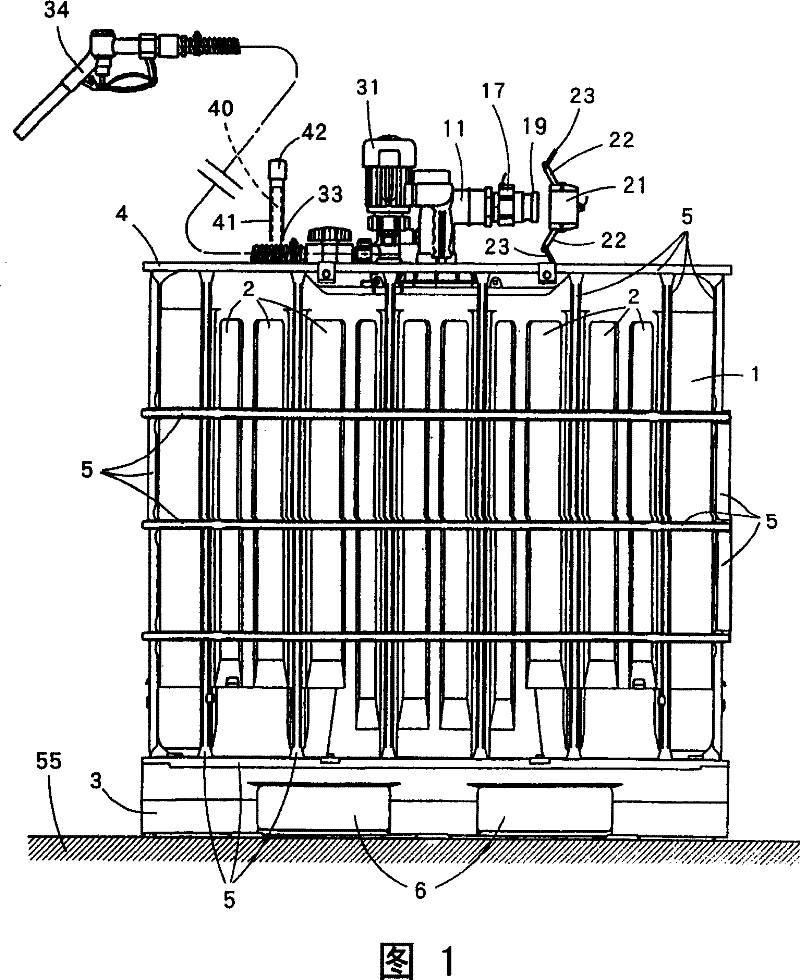

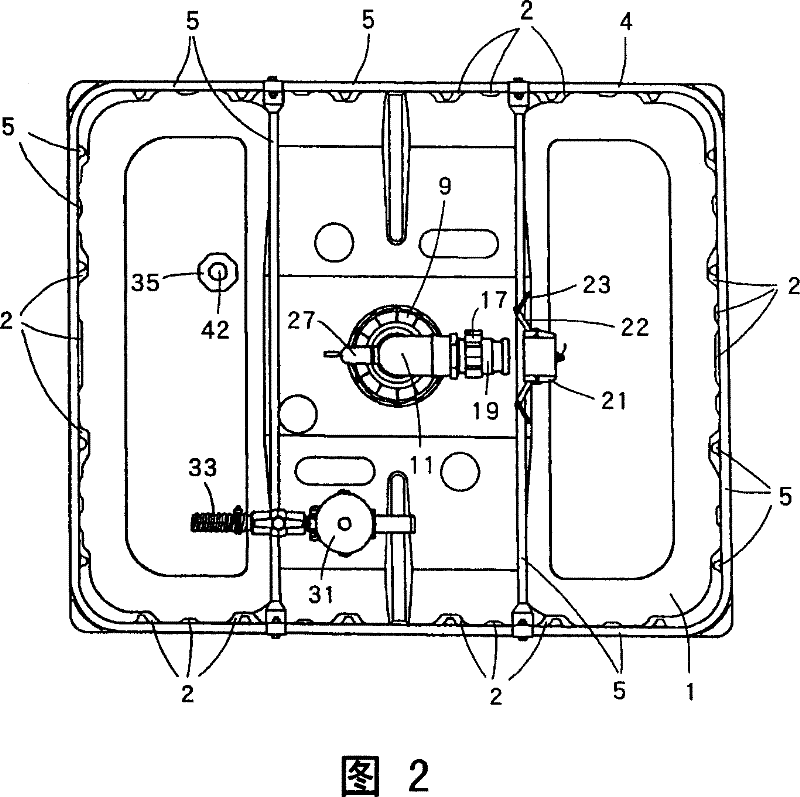

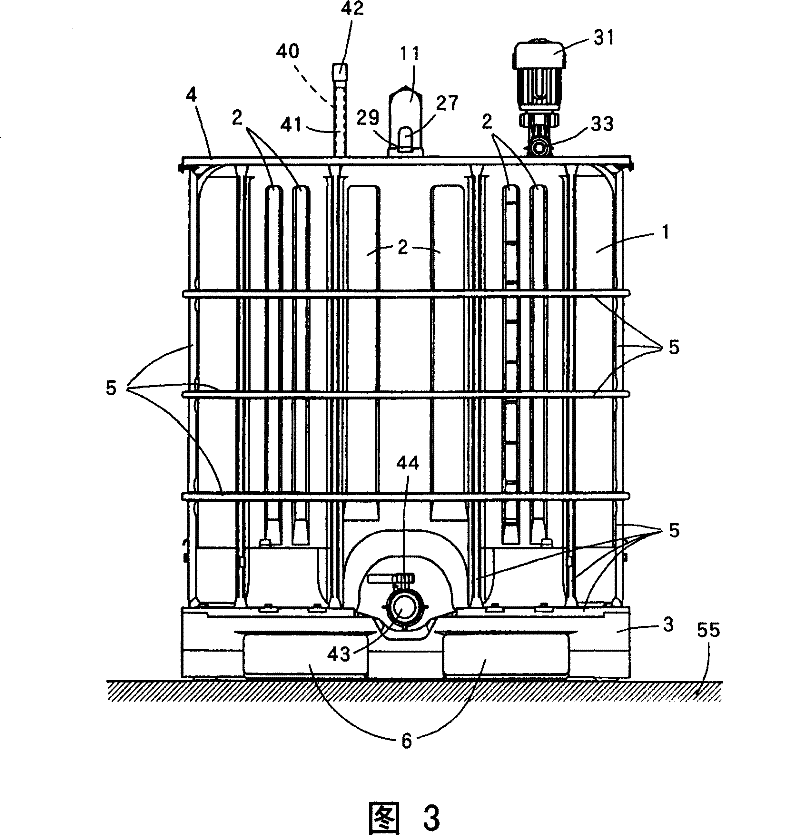

[0059] Next, the present invention will be described for a liquid storage tank of urea water as an aqueous solution of a reducing agent for purifying exhaust gas of a diesel engine and an illustrated embodiment of the supply device. Figure 1 to Figure 8 Among them, reference numeral 1 denotes a transparent or translucent liquid storage tank made of synthetic resin, which is in the shape of a substantially rectangular parallelepiped capable of holding about 1,000 liters of urea water, and a plurality of concave parts or concave ribs 2 for rigidity enhancement are formed on its peripheral surface .

[0060] The above-mentioned liquid storage tank 1 is placed, for example, on a platform 3 for transport by a forklift, and is stably installed in a suitable place such as a fuel supply base, a truck station, or a factory at ordinary times.

[0061] The numeral 4 in the figure represents the protective net installed around the above-mentioned tank 1, which is constructed by assemblin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com