Intelligent paying-off construction method in decoration engineering based on BIM technology

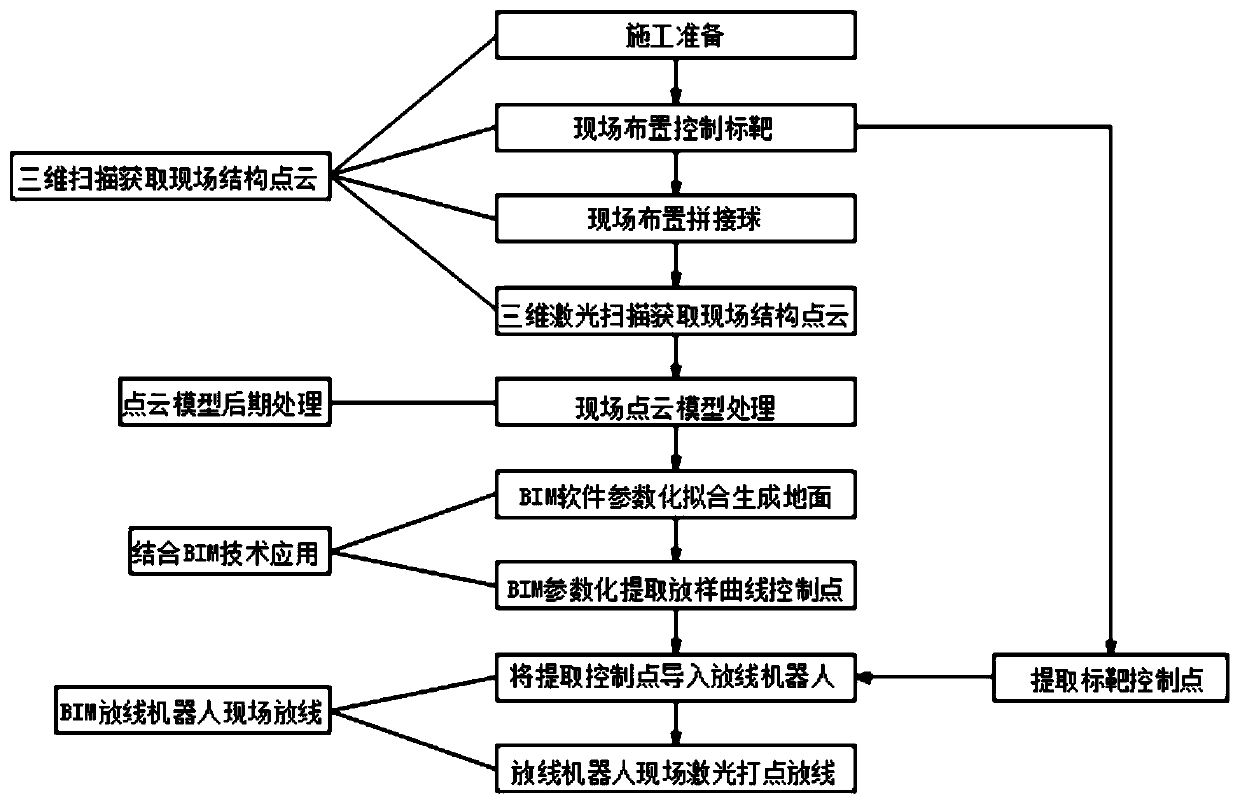

A construction method and engineering technology, applied in the field of construction engineering decoration, can solve the problems of large consumption, long construction period, and large impact on the site environment, and achieve the effects of precise lofting, saving construction period and reducing site pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: Do a good job of site construction preparation. Before 3D scanning, planar control targets are arranged in advance on the completed civil works. On-site planar targets are required to be posted. As a planar control target, the encrypted control network needs to be seen by the instrument. There are enough control points, and according to the volume size, appearance shape and construction site conditions of the completed civil works, arrange several 3D scanning stations (which can form closed wires), and set 3 stations on the buildings within the scope of each station. ~ 4 targets, which are the splicing of point cloud data measured by the stations of the 3D scanner. No less than 3 public splicing spheres should be arranged between each connected measuring station and the 3 splicing spheres cannot be in a straight line. The measuring station conducts three-dimensional scanning of civil engineering. Each measuring station should not be too far away to ensure t...

Embodiment 2

[0082] Embodiment 2, splicing the cloud models of each station refers to importing the point cloud model into Trimble RealWorks and adopting the point cloud stitching method under the absolute coordinate system, splicing the point cloud models obtained by the three-dimensional scanning of each station into a whole, and then the point cloud model Carry out noise reduction, filter and crop the point cloud model after noise reduction according to the reference objects required for setting out, and delete the noise points that do not belong to the completed civil engineering according to the true color and panoramic photos of the point cloud model;

Embodiment 3

[0083] Embodiment 3, import the floor point cloud and target coordinate points extracted after screening into the Rhino (rhino) software of BIM, and use Rhino+Grasshospper (rhino parametric plug-in) to generate the floor through parameterization of the imported floor point cloud Ground (grid dense, concave-convex ground), the Rhino model of the generated floor ground and target coordinate points is merged with the original structure decoration BIM model, the coordinate system is unified, and the control points are selected according to the characteristics of the lofting curve. Relative to the straight line segment, the two ends and the Midpoint; curved curve segment, in addition to extracting the endpoints and midpoints of different curvature radii, the extraction points should also be added according to the requirements of the processing material and the length of the curve, and the control points on the above curve can be obtained by running the algorithm in the Rhino environm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com