Multi-energy cooperative self-adaptive drying system and drying method

A drying system and self-adaptive technology, applied in solar heating systems, drying solid materials, drying gas layout, etc., can solve the problems of large temperature and humidity fluctuations in solar radiation drying room, difficult to achieve drying process, poor stability of working process, etc. , to achieve the effect of improving drying quality and drying efficiency, improving energy utilization rate and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

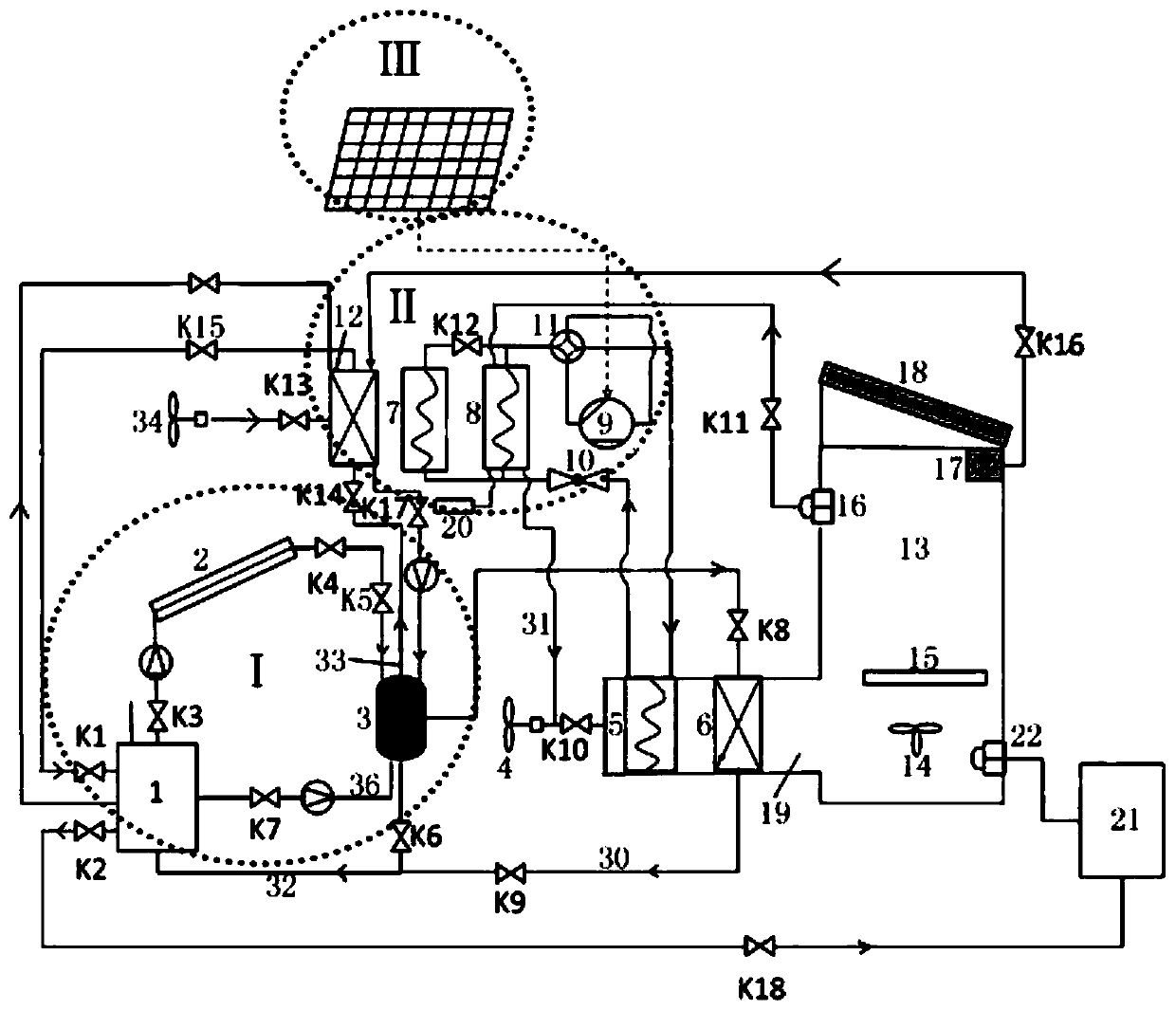

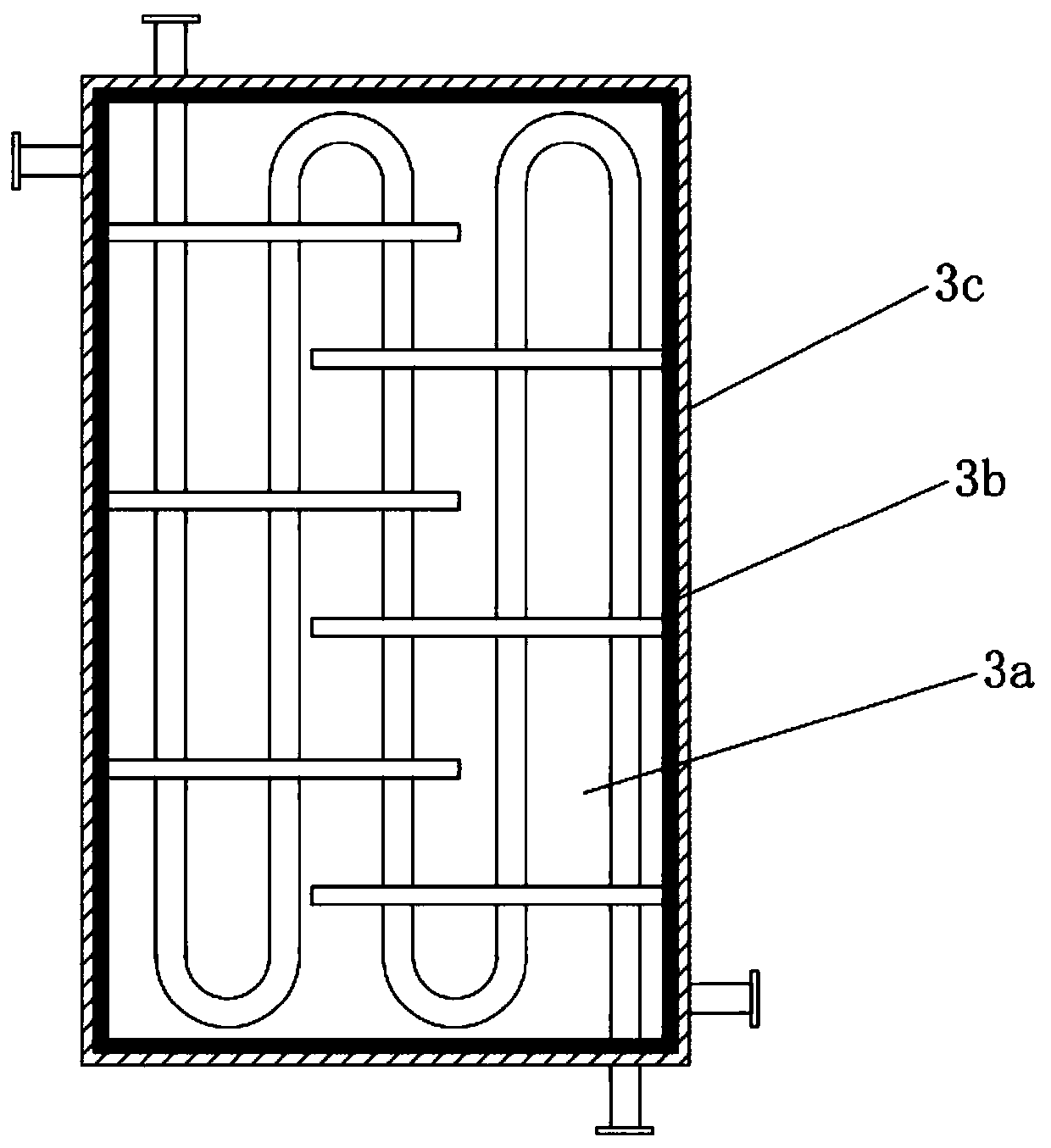

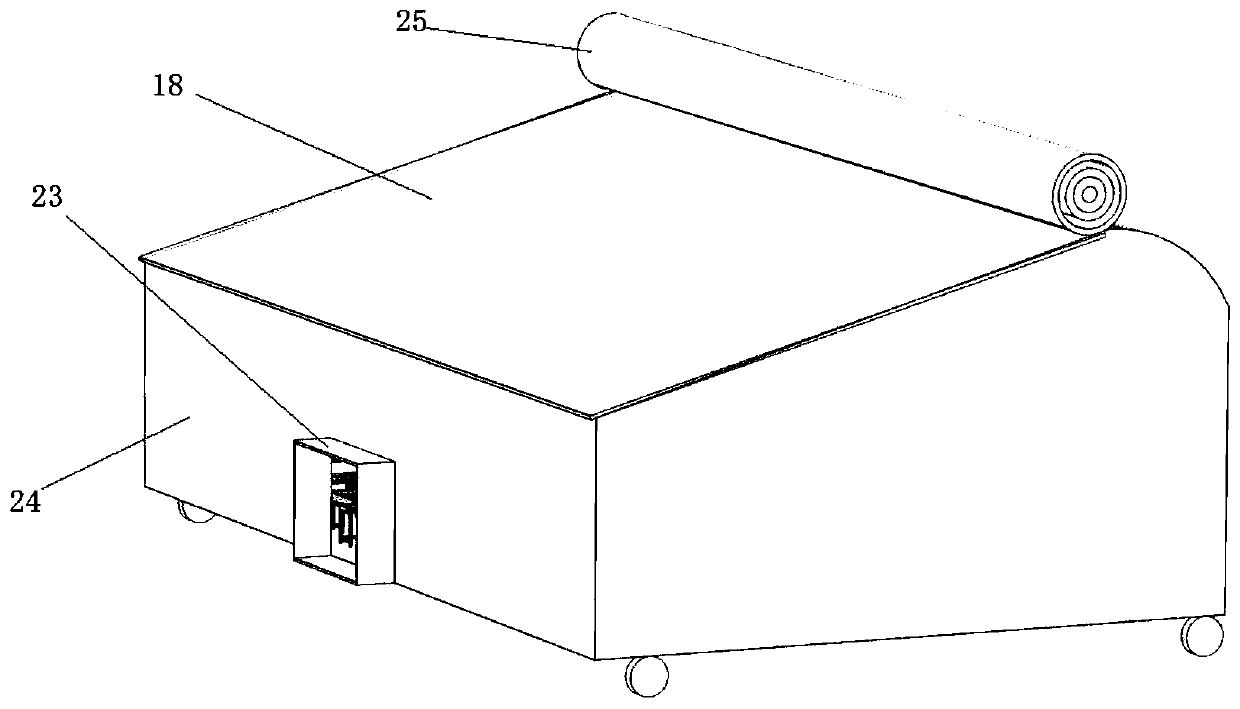

[0051] figure 1 Shown is a multi-energy cooperative self-adaptive drying system and drying method provided by the present invention, including a phase change heat storage drying mechanism I, a heat pump drying mechanism II, a photovoltaic power generation mechanism III and a solar radiation drying chamber 13; the solar radiation The first heat exchanger 6 and the first evaporative condenser 5 are also installed in the drying chamber 13, and the phase change heat storage drying mechanism I is connected to the first heat exchanger 6, and the heat pump drying mechanism II is connected to the first evaporative condenser 5 ; The photovoltaic power generation mechanism III is electrically connected to the heat pump drying mechanism II.

[0052] The first heat exchanger 6 is mainly used for heat exchange between the hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com