Micro downhole liquid station

A micro-fluid and micro-technology, applied in drilling equipment, wellbore/well components, wellbore/well valve devices, etc., can solve the problems of high cost of well completion and workover, long oil transmission distance, high risk of collision damage, etc. , to achieve the effect of eliminating downhole safety hazards, improving control delay, and avoiding workover operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more obvious and understandable, the preferred embodiments are described in detail as follows in conjunction with the accompanying drawings:

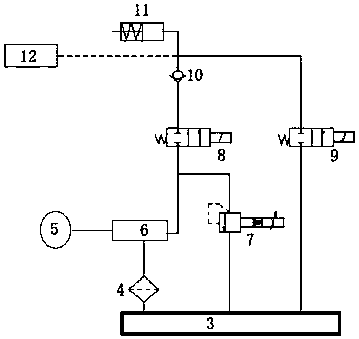

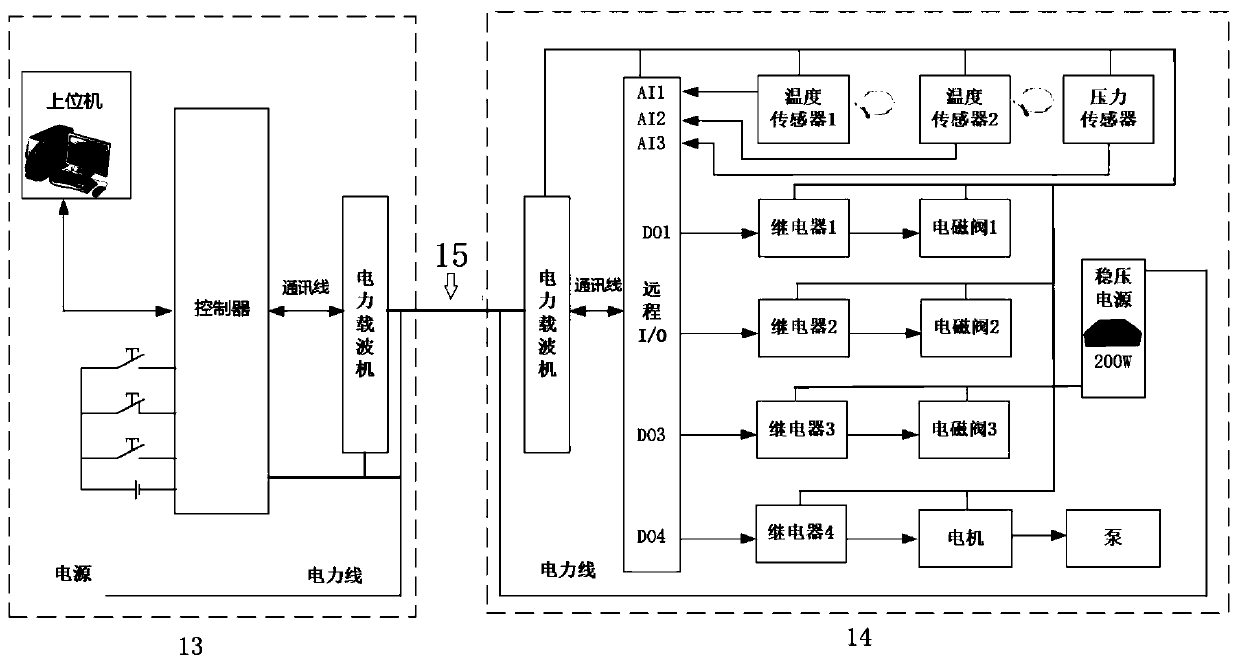

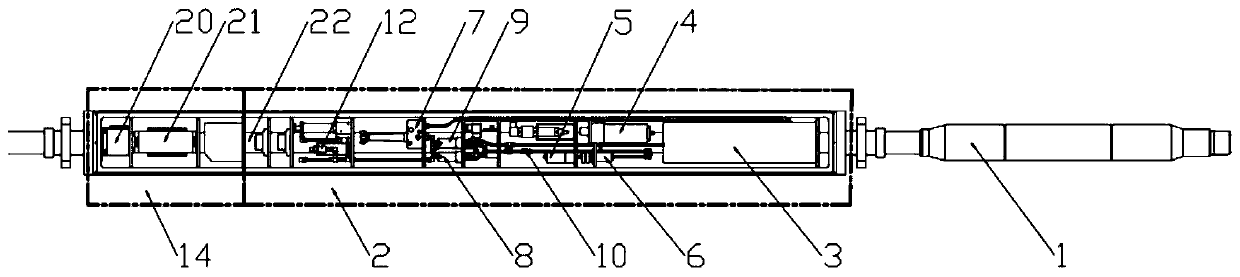

[0025] Such as Figure 1-5 As shown, the present invention provides a kind of miniature downhole liquid station, comprises the upper hole electrical control system 13, the intelligent composite continuous casing 15, the downhole electrical control system 14 and the downhole miniature liquid station 2; The upper hole electrical control system 13 passes the intelligent composite continuous casing 15 is connected with the downhole electrical control system 14, and the downhole electrical control system 14 is connected with the downhole micro liquid station 2; Connect one end of the box to one end of the box. The downhole electrical control system 14 includes a power carrier machine two, a remote data collection transmission module 21 and a relay 22; connected, the other end of the relay 22 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com