High-speed stirring drilling machine and construction method thereof

A high-speed mixing and drilling rig technology, applied in drilling equipment and methods, rotary drilling rigs, drill pipes, etc., can solve the problems of inconvenient transportation, low work efficiency, serious equipment loss, etc., to reduce construction procedures, improve construction efficiency, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

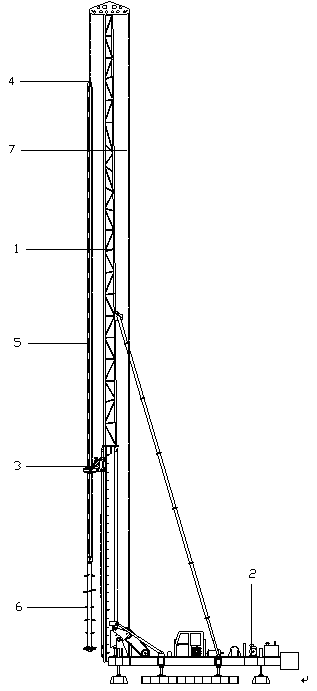

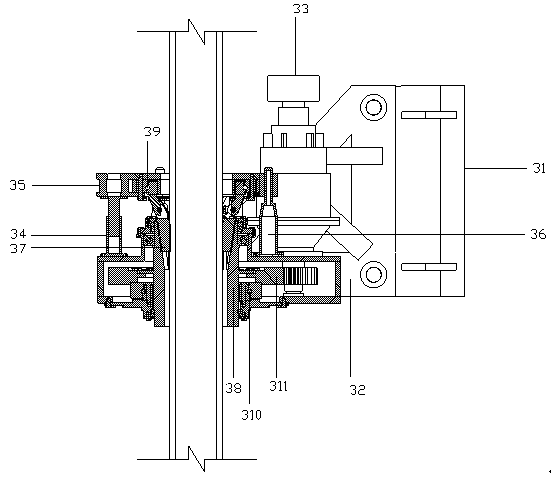

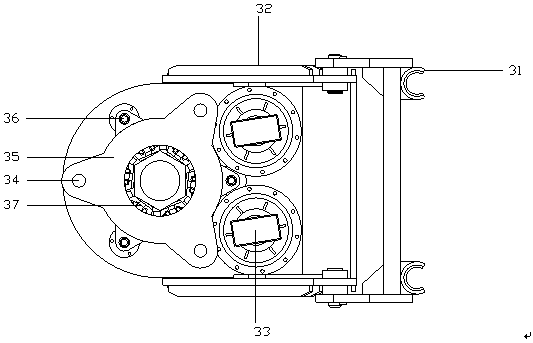

[0033] Such as Figure 1~3As shown, a high-speed mixing drilling rig is characterized in that it includes a pile frame 1, a chassis 2, a vertical rotary power system, a circular rotary power system, a rotary drive 3, a rotary pressure plate 4, a drill rod 5, a drill bit 6, and a chain 7. Solidified material pumping system, high-pressure gas supply system, and control system; the rotary drive 3 includes a guide rail 31, a bracket 32, a hydraulic motor 33, a compression cylinder 34, a connector 35, a limit rod 36, a block 37, Slewing sleeve 38, upper slewing bearing 39, lower slewing bearing 310, gear 311; the pile frame 1 and the chassis 2 are connected by bolts, and the vertical slewing power system and the hoop slewing power system are installed on the chassis 2, The rotary drive 3 is connected to the pile frame 1 through the guide rail 31, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com