Woollen sweater production machining device

A processing device and a technology for wool sweaters, which are applied in the field of wool sweater production, can solve problems such as slow drying speed, and achieve the effects of fast drying speed, convenient water removal, and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

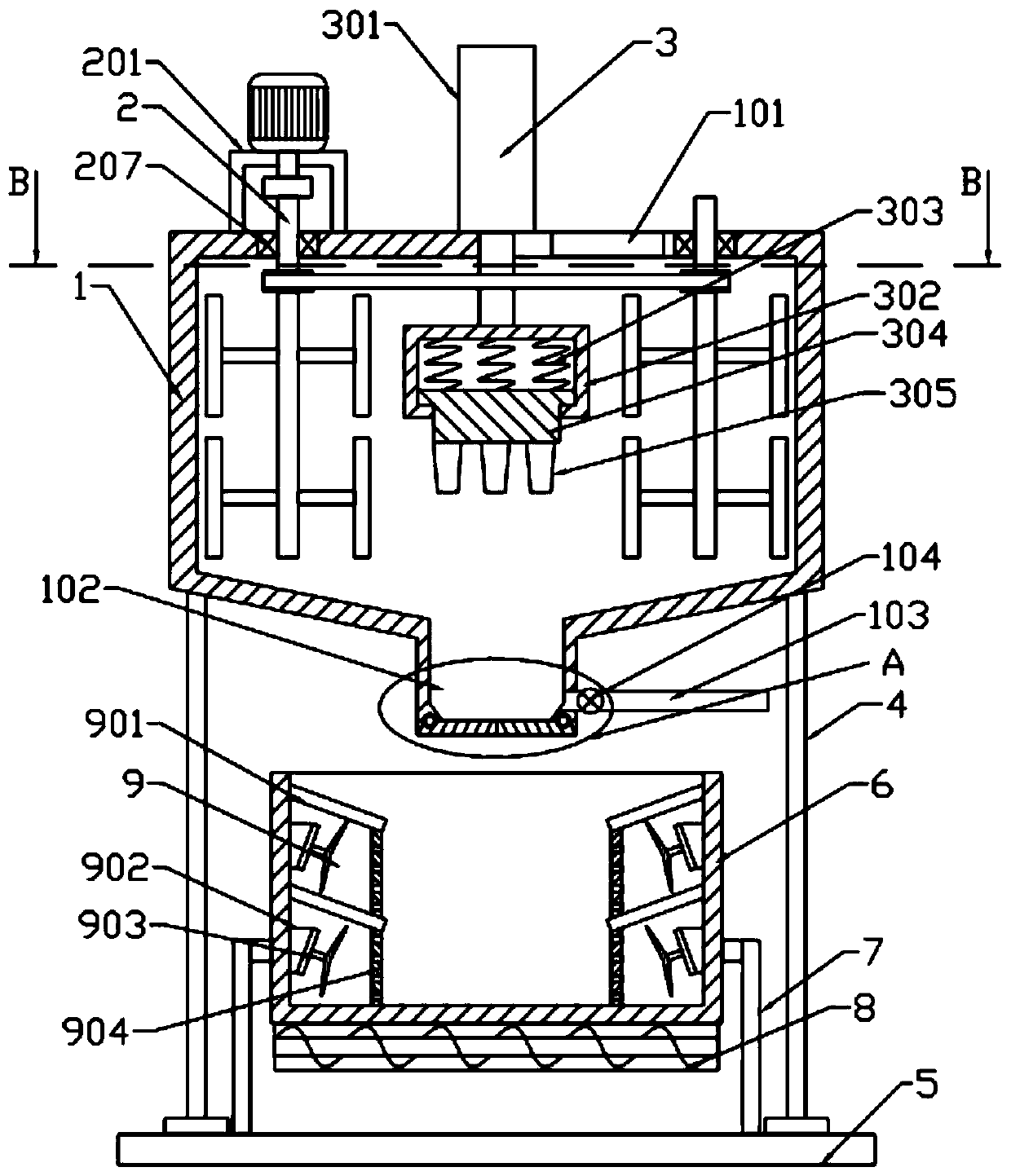

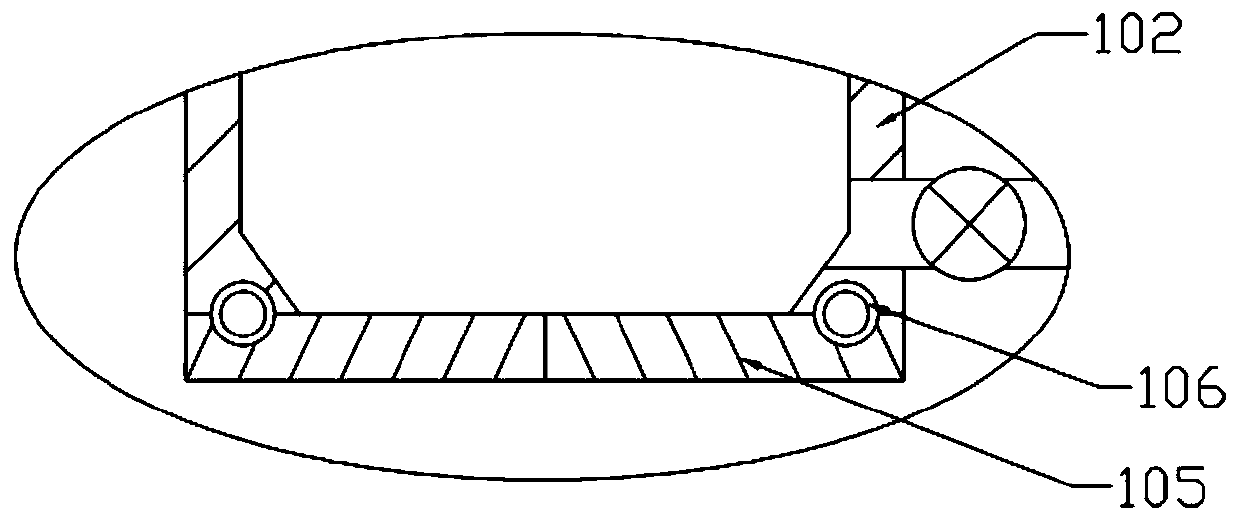

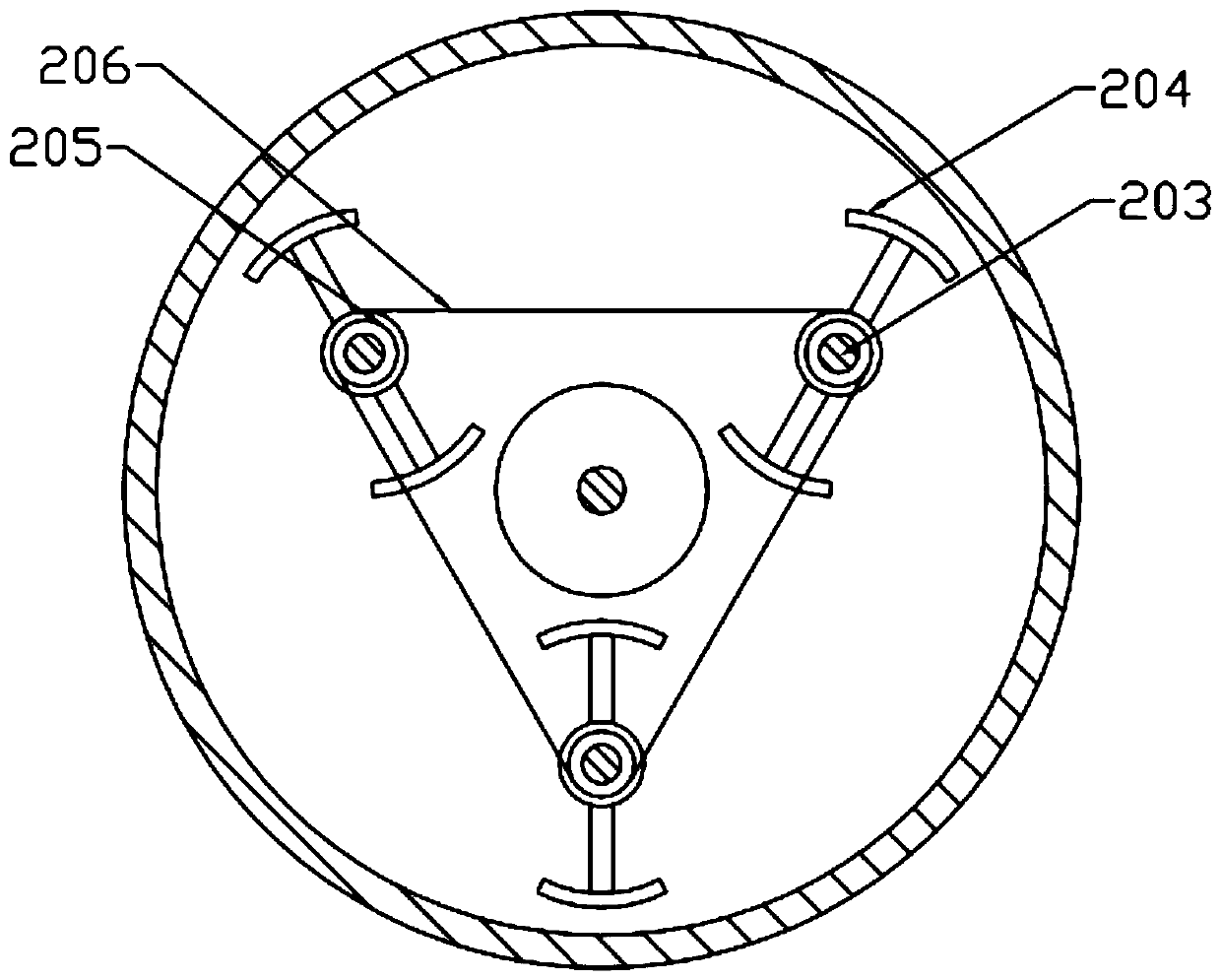

[0021] see Figure 1~4 , in an embodiment of the present invention, a sweater production and processing device includes a cleaning box 1, the top of the cleaning box 1 is provided with a feed port 101, and the bottom of the cleaning box 1 is provided with a discharge port 102, so A drain pipe 103 is installed on the discharge port 102, a valve 104 is installed on the drain pipe 103, and a support plate 105 is symmetrically installed on the left and right sides of the bottom of the discharge port 102, and the support plate 105 is twisted by force. The spring 106 is elastically connected to the discharge port 102. A cleaning device 2 is installed on the top of the cleaning box 1. The cleaning device 2 includes: a support 201, a servo motor 202, a rotating shaft 203, a cleaning blade 204, a synchronous wheel 205 and Synchronous belt 206, described bearing 201 is connected with the top of cleaning box 1 by screw, and servomotor 202 is installed on described bearing 201, and descri...

Embodiment 2

[0023] see figure 1 , in the embodiment of the present invention, the blowing device 9 includes: a baffle 901, a mounting table 902, a fan 903 and a ventilation plate 904, the baffle 901 is connected with the drying box 6 by screws, and the baffle 901 is arranged obliquely , the angle between the baffle plate 901 and the horizontal plane is 20°, the end of the baffle plate 901 is welded with a ventilation plate 904, and the bottom of the baffle plate 901 is installed with a mounting platform 902 on the inner wall of the drying box 6, A fan 903 is installed on the mounting table 902, and the fan 903 is arranged in parallel with the baffle plate 901, which can prevent the wool from being blown out of the drying box 6 when the fan 903 is blowing, and when the cleaned wool enters the drying box 6 , is heated by the heater 8, and is blown by the fan 903, so that the drying speed of the wool is faster.

[0024] In this woolen sweater production and processing device, wool and clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com