A kind of nut surface treatment process

A surface treatment and nut technology, which is used in drying cargo handling, drying solid materials, dryers, etc., can solve the problems affecting drying efficiency and drying time, so as to accelerate the speed of water removal, protect the nut, The effect of facilitating passage through curved channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described with reference to the accompanying drawings.

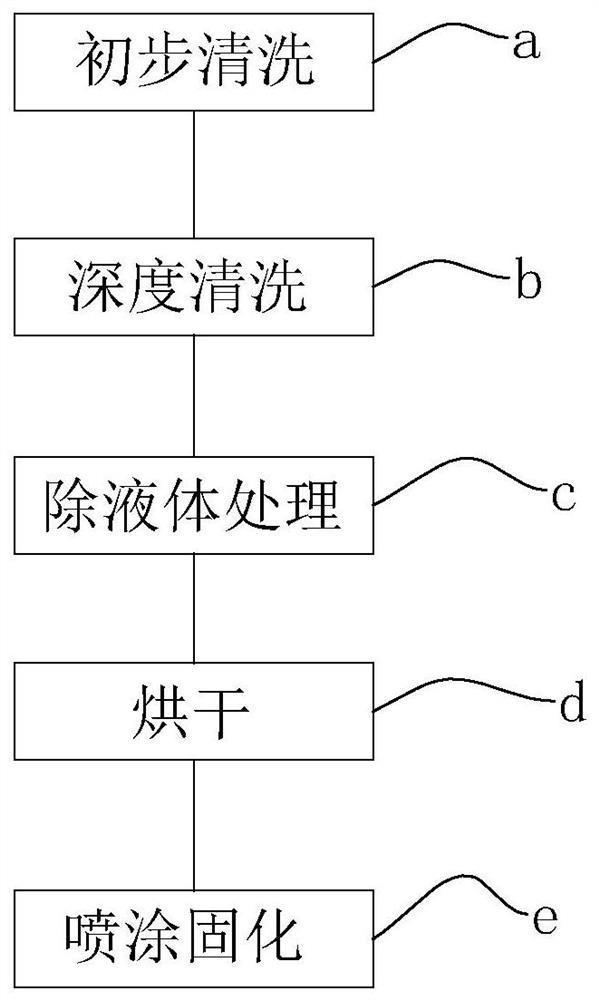

[0034] refer to figure 1 , figure 2 , which is a nut surface treatment process disclosed in this embodiment, includes the following steps:

[0035] a. Preliminary cleaning: Clean the nut with a washing machine to remove iron filings and sundries on the surface of the nut.

[0036] b. Deep cleaning: Put the cleaned nuts into the caustic soda solution for deep cleaning 1-3 times, and then put them into the hydrochloric acid solution for deep cleaning.

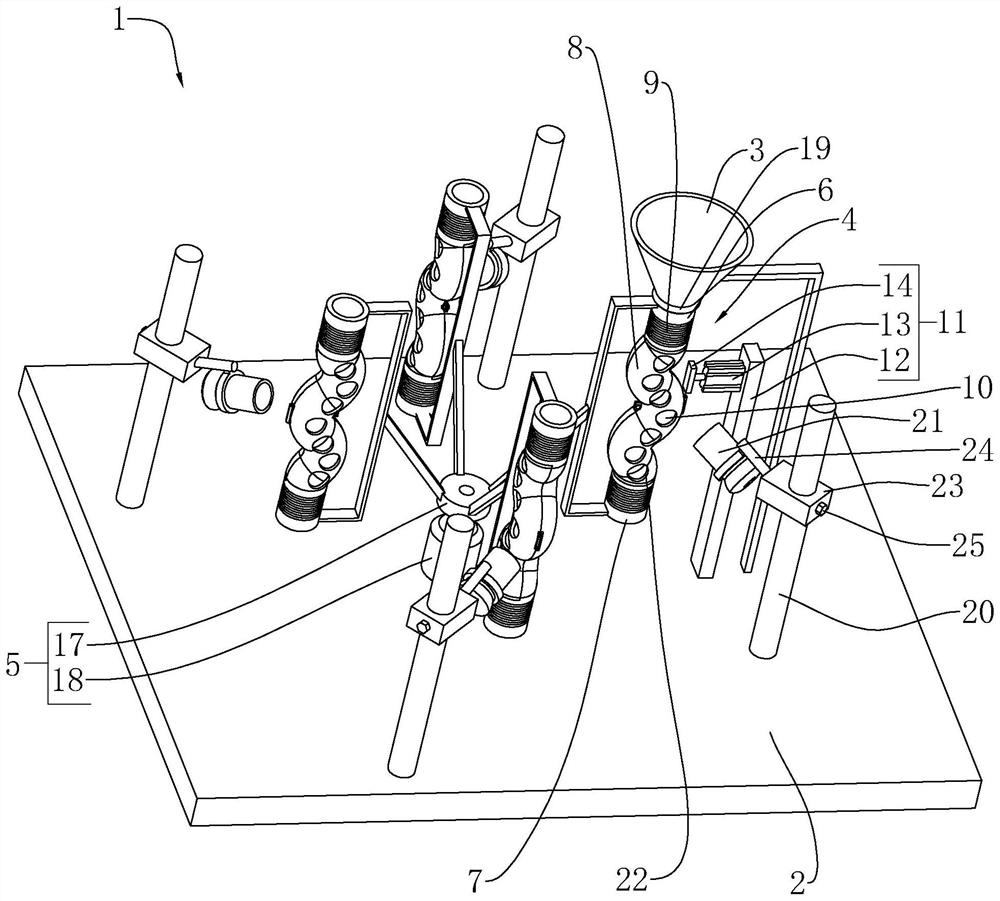

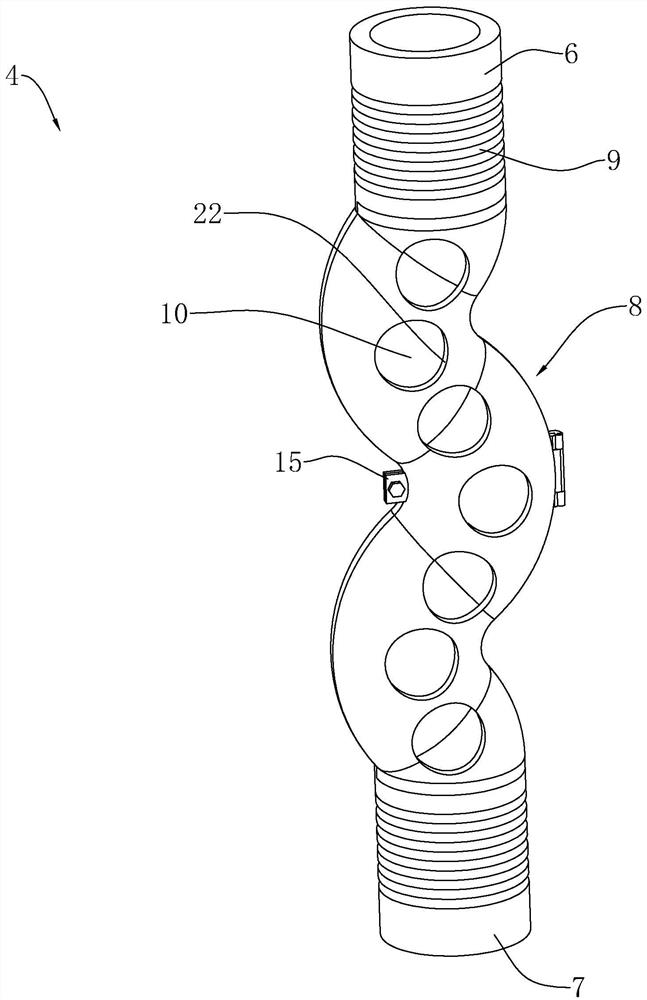

[0037] c. Liquid removal treatment: transport the cleaned nuts to the liquid removal device 1, and the liquid removal device 1 removes the liquid on the nuts.

[0038] d. Drying: Put the nuts into the drying device for drying.

[0039] e. Spraying and curing: Spray the dried nuts, put the sprayed nuts into a curing box for curing, and then get the finished nuts.

[0040] refer to figure 2 The liquid removal device 1 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com