Gray fabric water-removal equipment

A grey cloth and equipment technology, applied in the field of grey cloth dewatering equipment, can solve the problems of increasing the complexity of transportation and transportation cost, easy damage of water jet looms, poor dehumidification effect, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

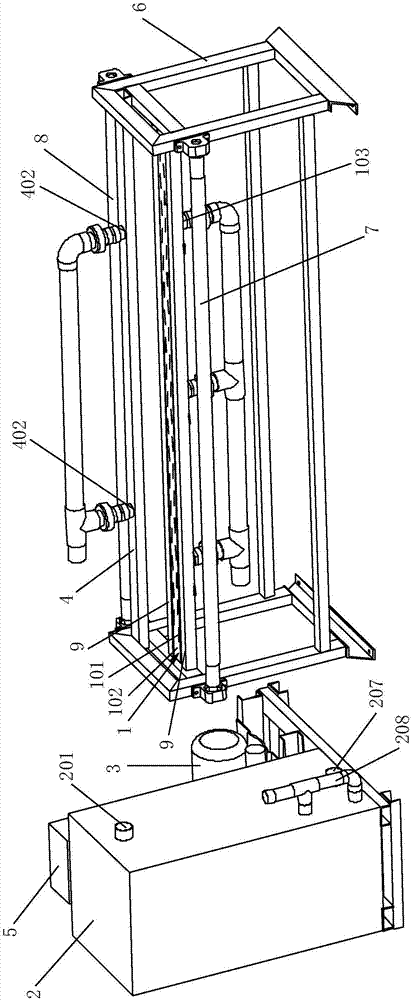

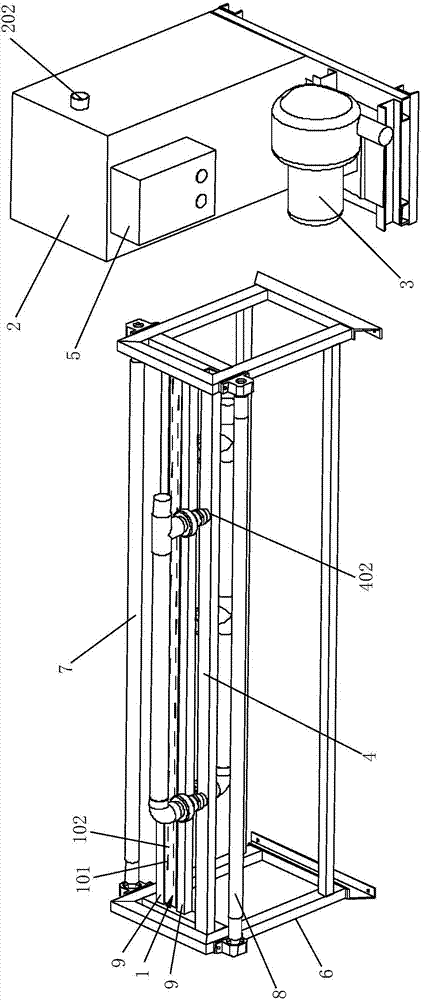

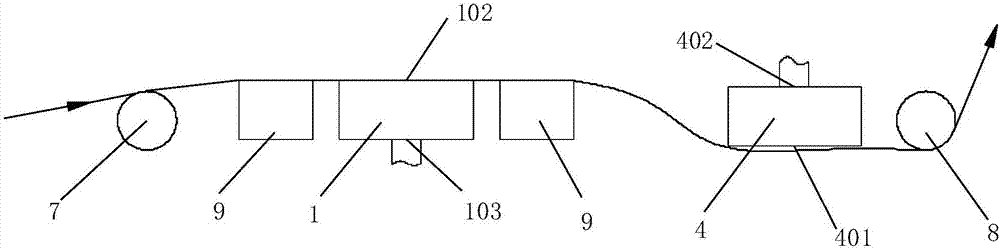

[0024] Such as Figure 1 to Figure 5 As shown, a gray cloth dewatering device is set in the transmission path for separating the gray cloth from large rolls, and includes a suction pipe 1, a water-gas separation device 2, a fan 3, and an air outlet pipe 4 connected in sequence through pipelines. The air suction pipe 1 and the air outlet pipe 4 are arranged sequentially along the conveying direction of the gray cloth, and the positions of the air suction pipe 1 and the air outlet pipe 4 facing the gray cloth are respectively provided with a suction port 101 and an air outlet (not marked in the figure), and the gray cloth is in the During the transmission process, the gray cloth is absorbed by the suction pipe 1, and the hot air is discharged through the air outlet pipe 4 to further dry the gray cloth, and the gray cloth realizes the dehydration process d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com