Pulse energy storage ceramic material and preparation method thereof

A ceramic material, energy storage technology, applied in electrical components, fixed capacitor dielectrics, circuits, etc., can solve the problems of limited energy storage performance, low electrical strength of energy storage materials, etc., to achieve performance improvement, good energy storage performance, performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

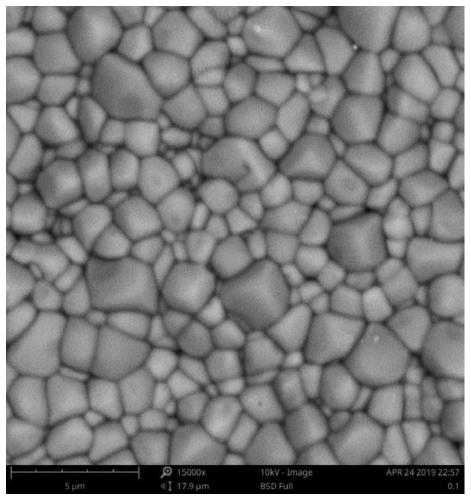

Image

Examples

Embodiment 1-7

[0035] Embodiments 1-7 provide a pulse energy storage ceramic material, including a main crystal phase, and the chemical general formula of the main crystal phase is Sr 0.7+x Ca y Bi 0.2 TiO 3 , where 0.01≤x≤0.05, 0.05≤y≤0.15.

[0036] A preparation method of a pulse energy storage ceramic material, comprising the following steps:

[0037] Step 1: Sr 0.7+x Ca y Bi 0.2 TiO 3 Main crystal phase powder synthesis; the purity is 99% of strontium carbonate, 99.5% of titanium dioxide, 99.5% of bismuth trioxide and 99% of calcium carbonate as starting materials, and the molar ratio between Sr, Ca, Bi and Ti is controlled It is Sr:Ca:Bi:Ti=(0.7+x):y:0.2:1, where 0.01≤x≤0.05, 0.05≤y≤0.15, ball milled and mixed evenly, and pre-fired at 900~1100℃ for 2~4 Hours, with furnace cooling to get Sr 0.7+x Ca y Bi 0.2 TiO 3 The main crystal phase powder; the ball milling process is: using zirconia balls as the ball milling medium, using deionized water as the solvent, and according to ...

Embodiment 8-17

[0050] Embodiments 8-17 provide a pulse energy storage ceramic material, comprising a main crystal phase and a modification additive, and the chemical general formula of the main crystal phase is Sr 0.7+x Ca y Bi 0.2 TiO 3 , where 0.01≤x≤0.05, 0.05≤y≤0.15. The modified additive is CeO 2 , Nb 2 o 5 、Nd 2 o 3 , ZnO, MnCO 3 , SiO 2 One or more of them account for 0.5-4.0% of the total mass of the pulse energy storage ceramic material.

[0051] Among the modified additives, CeO 2 , Nb 2 o 5 、Nd 2 o 3 , ZnO, MnCO 3 , SiO 2 The percentage content of the total mass of the pulse energy storage ceramic material is CeO 2 : 0.2~1.0%, Nb 2 o 5 : 0.5~2.5%, Nd 2 o 3 : 0.1~2.0%, ZnO: 0.2~1.2%, MnCO 3 : 0.1~0.6%, SiO 2 : 0.1 to 1.0%.

[0052] Step 1: Sr 0.7+x Ca y Bi 0.2 TiO 3 Main crystal phase powder synthesis; the purity is 99% of strontium carbonate, 99.5% of titanium dioxide, 99.5% of bismuth trioxide and 99% of calcium carbonate as starting materials, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com