A composite concrete viscosity-reducing material and its application

A concrete and composite technology, applied in the field of building materials, can solve the problem of high viscosity of concrete, and achieve the effects of good dispersion, good adaptability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

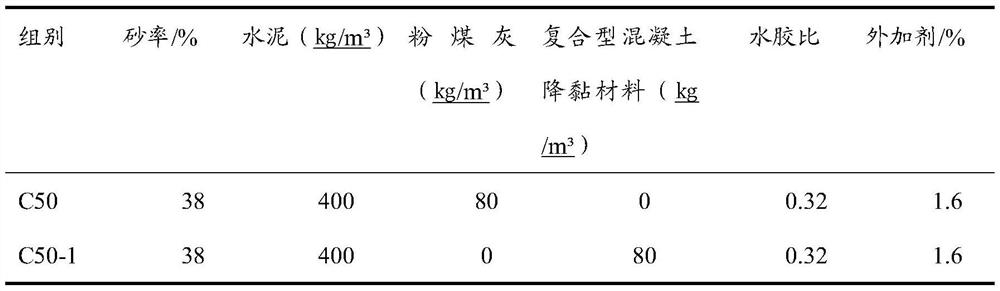

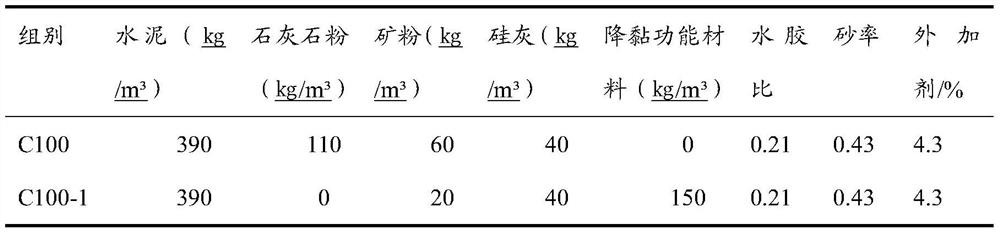

Examples

Embodiment 1

[0027] The preparation method of a composite concrete viscosity-reducing material provided in this embodiment comprises the following steps:

[0028] (1) Preparation of hydrophilic monomers:

[0029] Add 100g of methacrylic acid into the three-necked flask, add NaOH aqueous solution (10wt%) and N,N-dimethyl-1,3-propanediamine molar ratio of 0.6:1 and N,N-dimethyl- 1,3-propanediamine, then add KOH equivalent to 0.35% of the total weight of methacrylic acid, NaOH aqueous solution (10wt%) and N,N-dimethyl-1,3-propanediamine as a catalyst, under nitrogen protection , start electric stirring, and react at 85°C for 4 hours. After the reaction is completed, Intermediate C is obtained; Intermediate C is washed with water, and then the washed Intermediate C is added to a three-necked flask, and 300g of ethanol is added, according to Intermediate C: 3- Sodium chloro-2-hydroxy-propylsulfonate:sodium chloroacetate is 0.4:1:1.9 molar ratio, add 3-chloro-2-hydroxy-propylsulfonate and sodiu...

Embodiment 2

[0044] The preparation method of a composite concrete viscosity-reducing material provided in this embodiment comprises the following steps:

[0045] (1) Preparation of hydrophilic monomers:

[0046] Add 100g of methacrylic acid into the three-necked flask, and add NaOH aqueous solution (10wt%) and N,N-dimethyl-1,3-propanediamine according to the molar ratio of NaOH and N,N-dimethyl-1,3-propylenediamine of 1.3:1. 1,3-propanediamine, then add sodium methoxide equivalent to 0.8% of the total weight of methacrylic acid, NaOH aqueous solution (10wt%) and N,N-dimethyl-1,3-propanediamine as a catalyst, under nitrogen Under protection, start electric stirring, and react at 85°C for 4 hours. After the reaction is completed, wash the product with water to obtain Intermediate C; then add the washed Intermediate C to a three-necked flask, add 300g of ethanol, and follow Intermediate C: 3-chloro -2-Hydroxy-propylsulfonate sodium:sodium chloroacetate=0.65:1:2.2 molar ratio, add 3-chloro-2...

Embodiment 3

[0061] The preparation method of a composite concrete viscosity-reducing material provided in this embodiment comprises the following steps:

[0062] (1) Preparation of hydrophilic monomers:

[0063] Add 100g of methacrylic acid into the three-necked flask, and add NaOH aqueous solution (10wt%) and N,N-dimethyl-1,3-propanediamine according to the molar ratio of NaOH and N,N-dimethyl-1,3-propylenediamine of 0.69:1. 1,3-propanediamine, then add KOH equivalent to 1.2% of the total weight of methacrylic acid, NaOH aqueous solution (10wt%) and N,N-dimethyl-1,3-propanediamine as a catalyst, under nitrogen protection , start the electric stirring, and react at 85°C for 4 hours. After the reaction is completed, Intermediate C is obtained; Intermediate C is washed with water, and then the washed Intermediate C is added to a three-necked flask, and 300g of ethanol is added, according to Intermediate C: 3- Sodium chloro-2-hydroxy-propylsulfonate:sodium chloroacetate=0.5:1:2.2 molar rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| methylene blue value | aaaaa | aaaaa |

| loss on ignition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com