Deep fluorine removal agent as well as preparation method and application thereof

A defluoridation agent, deep technology, applied in the field of pollutant treatment, can solve the problems of unfavorable large-scale quantitative production, complex preparation process of defluoridation agent, harsh process conditions, etc., achieve obvious defluorination effect, stable water output effect index, and run low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

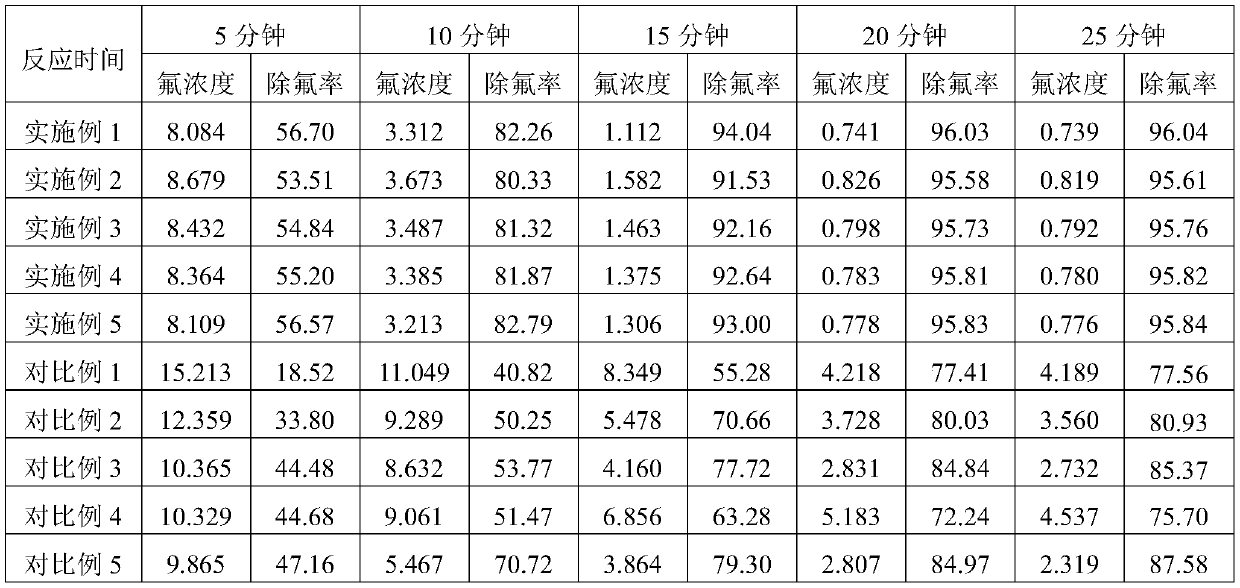

Examples

Embodiment 1

[0022] The deep defluoridation agent described in this embodiment is composed of the following components in parts by mass: 70 parts of polyaluminum chloride, 10 parts of aluminum sulfate, 5 parts of ferric chloride, 10 parts of slaked lime, 3 parts of sodium metaaluminate, 2 parts of methyl diallyl ammonium chloride. Weigh the raw materials in selected parts by mass, grind, stir, and fully mix to prepare the deep defluoridation agent CF-1.

Embodiment 2

[0024] The deep defluoridation agent described in this embodiment is composed of the following components by mass: 66 parts of polyaluminum chloride, 12 parts of aluminum sulfate, 6 parts of ferric chloride, 12 parts of slaked lime, 2 parts of sodium metaaluminate, 2 parts of methyl diallyl ammonium chloride. Weigh the selected raw materials in parts by mass, grind, stir, and fully mix to prepare the deep defluoridation agent CF-2.

Embodiment 3

[0026] The deep defluoridation agent described in this embodiment is composed of the following components by mass: 68 parts of polyaluminium chloride, 11 parts of aluminum sulfate, 5 parts of ferric chloride, 11 parts of slaked lime, 4 parts of sodium metaaluminate, 1 part of methyl diallyl ammonium chloride. Weigh the selected raw materials in parts by mass, grind, stir, and fully mix to prepare the deep defluoridation agent CF-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com